Spotted: The global carbon capture and storage (CCS) market has increased significantly in recent years, and is projected to continue growing as the world looks for more ways to decarbonise. Often though, these solutions focus on storage underground, offering no commercial value. Paebbl’s technology, by contrast, turns carbon dioxide into a useful building material.

Paebbl took the inspiration for its technology directly from nature. Carbon dioxide mineralisation, the process by which CO2 solidifies and turns into stone, is naturally occurring, but takes centuries to complete. Paebbl has found a non-energy-intensive way to accelerate mineralisation to make it over one million times faster, taking just 60 minutes.

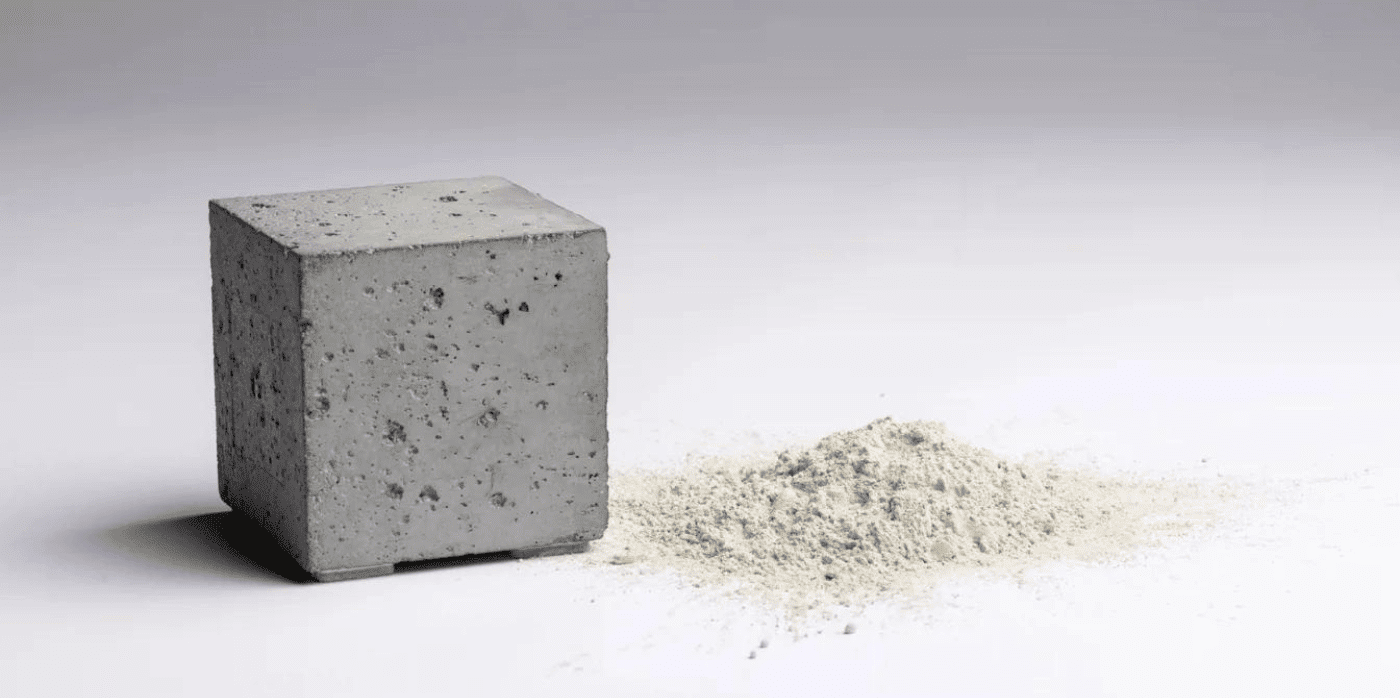

The company takes CO2 captured from the air or directly from polluting industrial sites and combines it with abundantly available silicate rocks to produce a carbon-negative raw material.

This end product can be used as a filler in construction, as a replacement for parts of a concrete mix, and as paper, among other purposes. Unlike many methods of carbon storage or carbon-negative materials, the company also states that its material can be competitively priced.

Paebbl recently commissioned a 500-litre batch production unit, called Obelix, which has enabled the company to boost production capacity by 100 times in just half a year. With Obelix, Paebbl can create 100 tonnes of sustainable construction materials every year. The company expects to start shipping samples early 2024.

It’s not just the construction industry that’s using carbon to create new materials – Springwise has also spotted innovators turning it into chemicals and E-jet fuels.

Written By: Matilda Cox