Spotted: The fashion industry has been getting a lot of criticism lately for its unsustainable practices. And for good reason – 87 per cent of the fibres and materials used to make clothing will end up in either incinerators or landfills. Luckily, many companies are now working to solve this problem, including startup Unspun.

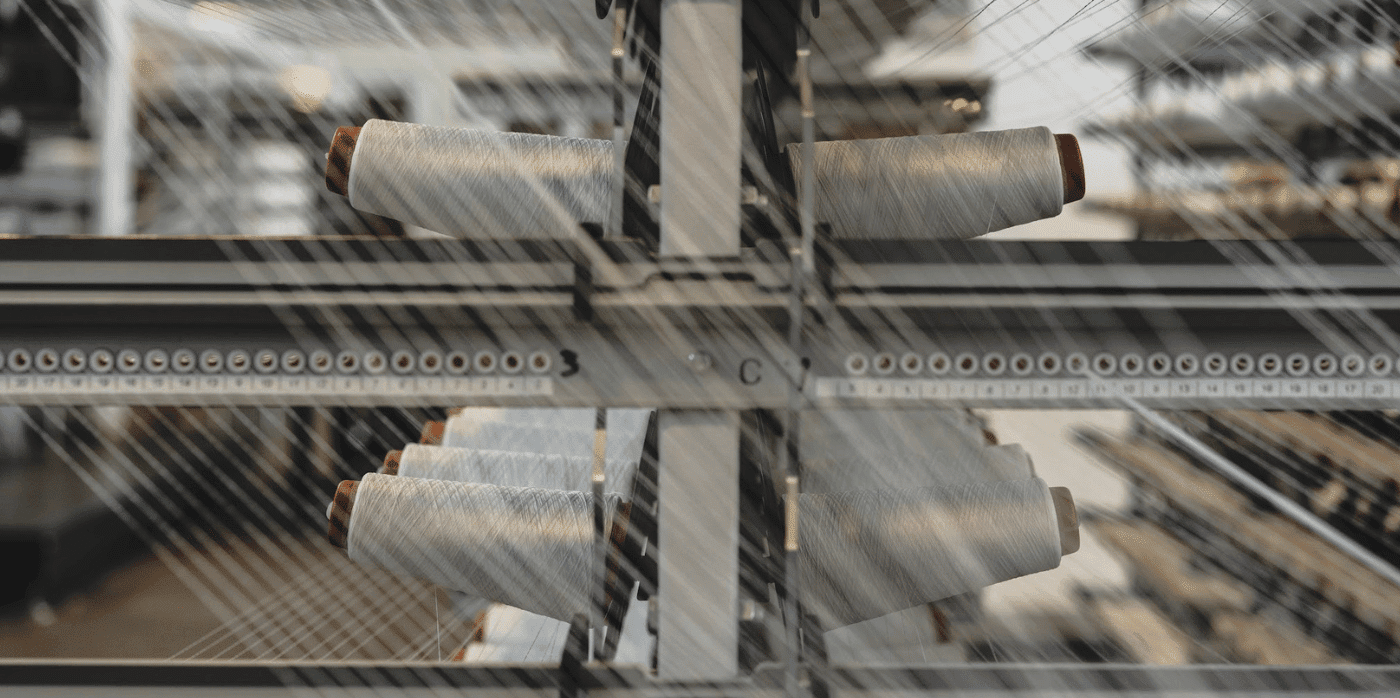

Unspun has developed a unique solution to make textile production more sustainable. The company has developed automated, 3D weaving micro-factories, called Vega, that can weave a pair of trousers in 10 minutes. The factories allow brands to make products locally, reducing the need for manufacturing in large quantities – a major cause of waste.

Unspun highlights that the textile industry’s slow adoption of new technologies has hindered progress in addressing fashion’s impact on climate change. The company hopes to change this by decentralising fashion production and reducing greenhouse gas emissions from shipping and waste.

Unspun recently announced it has raised $14 million (around €17.6 million) in a series A funding round led by Lowercarbon, which will be used to support the development of Vega micro-factories. The company is also developing techniques to ‘unspin’ garments back into yarns, so that they can be re-woven into new products. The ultimate goal is to help brands achieve a local, circular supply chain for woven products.

In addition to Unspun, Springwise has spotted a number of other innovations in the archive that are helping create a more sustainable fashion industry. These include the development of regenerative fibres and carbon-negative textiles.

Written By: Lisa Magloff