Spotted: 3D printing is an additive manufacturing process that creates objects by building them up layer by layer. The technology has been gaining traction in recent years due to its potential benefits, which include reduced construction waste and increased design flexibility. 3D printing is particularly well-suited to the construction industry, where it can be used to create bespoke structural elements quickly and efficiently. One new approach to 3D printing, which is being developed by Imperial College London, EMPA, and other institutions, uses fleets of drones that collectively build a structure from the air.

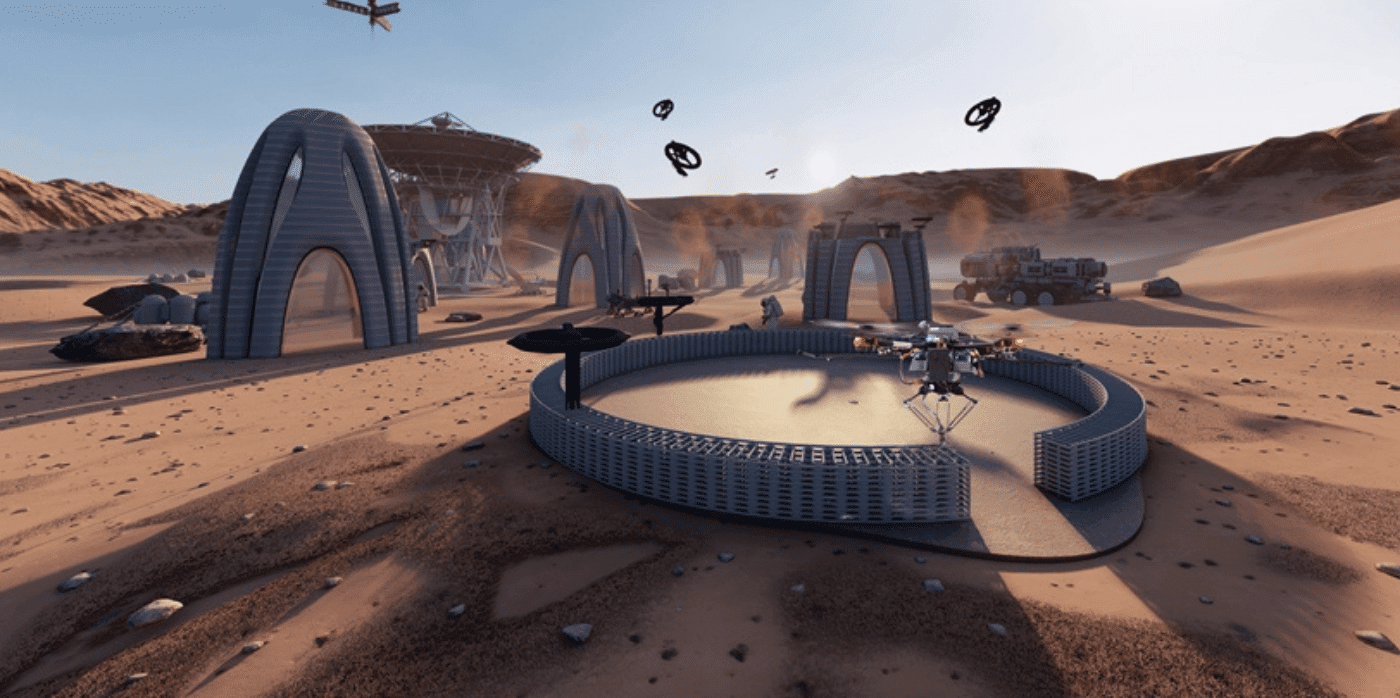

The new system for 3D printing is called Aerial Additive Manufacturing, or AAM. Just like a colony of bees, it involves a fleet of drones working together from a single blueprint. Also like the operation of a colony, AAM consists of two types of drones: BuilDrones, which deposit materials during flight, and quality-controlling ScanDrones, which monitor the BuilDrones’ performance and inform their next manufacturing steps.

The system is designed to be scalable and modular, so that it can be used to construct everything from small buildings to large bridges. This means that AAM has the potential to be faster, cheaper, and more efficient than traditional construction methods. While the drones are autonomous, the entire process can be monitored and adjusted by a human controller.

The system was tested with four cement-like mixtures. The drones had to continuously assess the printed geometry and adapt accordingly to meet the build specifications. Next, the researchers will partner with construction companies to validate the solutions and provide repair and manufacturing capabilities.

With the advancement of drone technology, Springwise has spotted a plethora of drone-based innovations. Among these are robot forest rangers that plant trees and drones that use AI to detect abnormal patterns of gas that indicate the presence fire.

Written By: Katrina Lane