Spotted: As the global population, living standards, and economy continue to grow, along with improvements in water supply, so does the volume of wastewater. Each year, 380 billion m3 of municipal wastewater is generated globally, with very little of that ever being recycled. But, on-site wastewater can be reused to create a circular waste economy and reduce the amount of freshwater that would be wasted, and this is where Epic Cleantec comes in.

Born out of work with the Bill and Melinda Gates Foundation’s Reinvent the Toilet Challenge, Epic was founded to use this untapped potential. Epic deploys onsite water reuse systems into the built environment, making cities more resilient, sustainable, and water secure. The company’s OneWater system captures and processes a building’s wastewater, including black and grey water. The process allows a building to recycle up to 95 per cent of its water on-site for reuse in toilet and urinal flushing, laundry, irrigation, and cooling towers.

Epic’s approach produces three outputs: recycled water, recovered heat energy from wastewater to improve building energy efficiency, and carbon-rich soil nutrients for local agriculture and landscaping use. And through a partnership with Devil’s Canyon Brewing Co., Epic Cleantec is also turning this wastewater into beer.

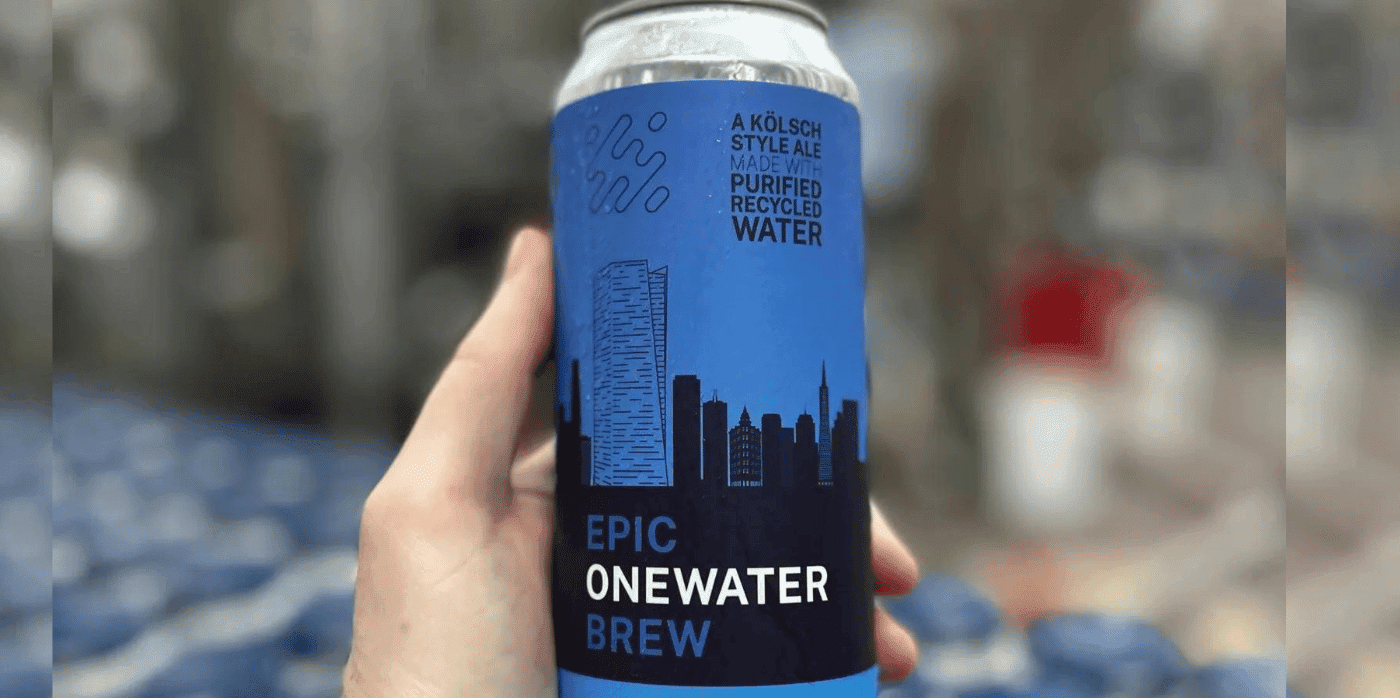

Using its technology, Epic transformed wastewater from a high-rise apartment block in San Francisco into over 2,000 gallons of recycled water, which Devil’s Canyon used to create Epic OneWater Brew – a Kölsch-style ale.

At a time when the world is rapidly urbanising and using more and more water, it’s no wonder why there are so many ways to address water scarcity. In the archive, Springwise has spotted one company that uses wastewater to power biomanufacturing, while another is harvesting water from the air.

Written By: Anam Alam