Spotted: Every year, the fashion industry is responsible for 10 per cent of global carbon emissions, which is more than the maritime and aviation sectors combined. Because of this, more and more textile brands are looking for innovative ways to cut back on their carbon footprints. Enter Rubi Laboratories, which makes textiles using captured carbon dioxide.

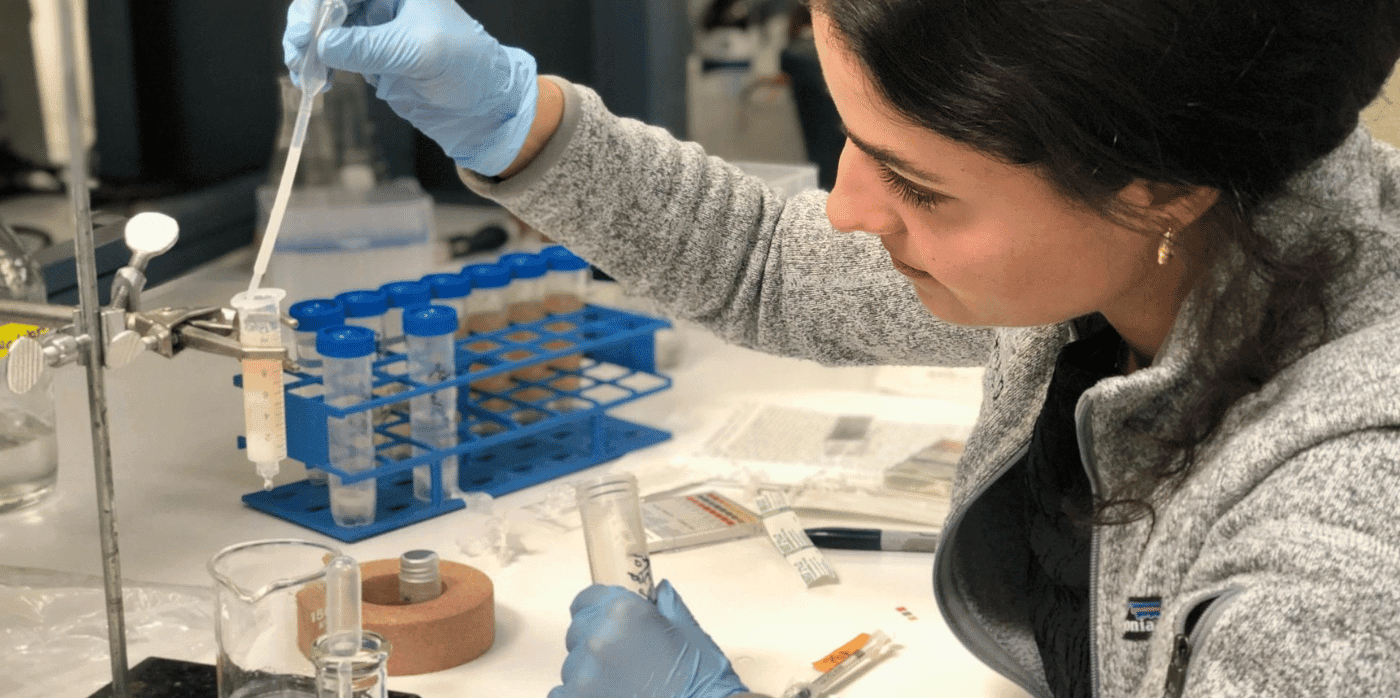

The US-based startup creates textiles through its patent-pending, cell-free biocatalytic process. First, the company captures CO2 from the waste streams of manufacturing processes using its proprietary enzyme system. The gas is then converted into cellulose pulp, which is used to create viscose-based yarn or fibres to be used in textiles.

Viscose, also known as Rayon, is normally made from wood pulp, but Rubi Labs’ solution means no trees need to be cut down to produce the popular material. Using its innovative technology, the startup can create fabrics made 100 per cent from carbon emissions, with almost no water or land needed. The process also produces zero waste and, at the end of their usable life, the textiles will naturally biodegrade.

Earlier this year, the biotech startup secured an additional $8.7 million (around €8 million) in seed funding, bringing its total funds to $13.5 million (around €12.5 million). The extra funding has allowed Rubi Labs to enter its next stage of testing, including projects with Ganni, Reformation, and Urban Outfitters.

The textile industry is booming with sustainable alternative options, and Springwise has spotted fully recyclable 3D-printed footwear, plant-based plastic-free alt leather, and baby shoes that will dissolve in water.

Written By: Anam Alam