Spotted: Fashion design, like many other areas of design, is increasingly digital. Large fashion manufacturers now often digitise their fabrics and then use tools to design products digitally using these fabrics, making sure all measurements and seams are accurate, before manufacturing the physical garments.

However, 3D imaging technology can be very expensive, so smaller designers often have no choice but to produce many physical samples first, each with a different fabric and measurements, wasting time, money, and resources. Bandicoot Imaging Sciences is working to change this with a solution that can quickly and cheaply capture fabrics and materials digitally, without any special equipment, and create digital twins that can be used with other digital design tools.

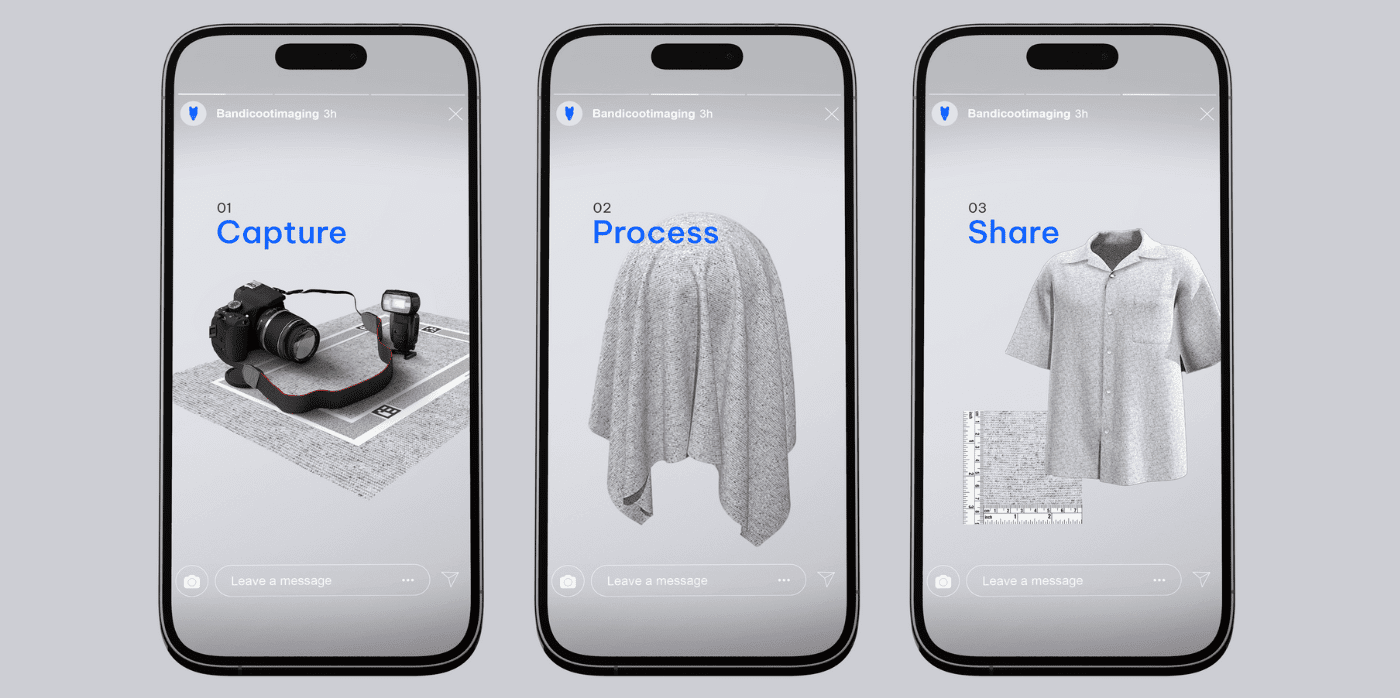

Bandicoot’s Shimmer View system allows designers to scan their physical fabrics with just 10 minutes of training. The photos are then uploaded to the web app where the cloud service automatically generates physically based texture maps and fabric renders. These can be used with other 3D design tools or digitally shared with customers.

Fashion is big business, and this is reflected in Bandicoot’s recent pre-seed funding round. The company raised AU$1 million (around €605,000) to boost innovation and grow the technology, including the addition of new capabilities to the cloud-based platform. Bandicoot CGO Jørgen Sevild told Springwise that “Bandicoot is the fastest growing material digitisation technology on the market, and we are constantly looking to improve the user experience and impact of our pioneering technological developments.”

From upcycling textiles into new products to delivering integrated analysis of the complete fashion supply chain, there is a wide range of innovations aimed at reducing waste in fashion.

Written By: Lisa Magloff