Spotted: To reach net zero by 2050, we need to drastically reduce our reliance on fossil fuels, and that means ramping up green energy generation. According to the International Energy Agency (IEA), that involves adding 390 gigawatts of wind power generation capacity every year by 2030. But, rising upfront construction costs, particularly for offshore farms, could compromise that goal, with several offshore projects in the US needing to be cancelled or renegotiated due to issues around financing. Hoping to make wind farm construction more affordable is Colorado-based Keystone Tower Systems.

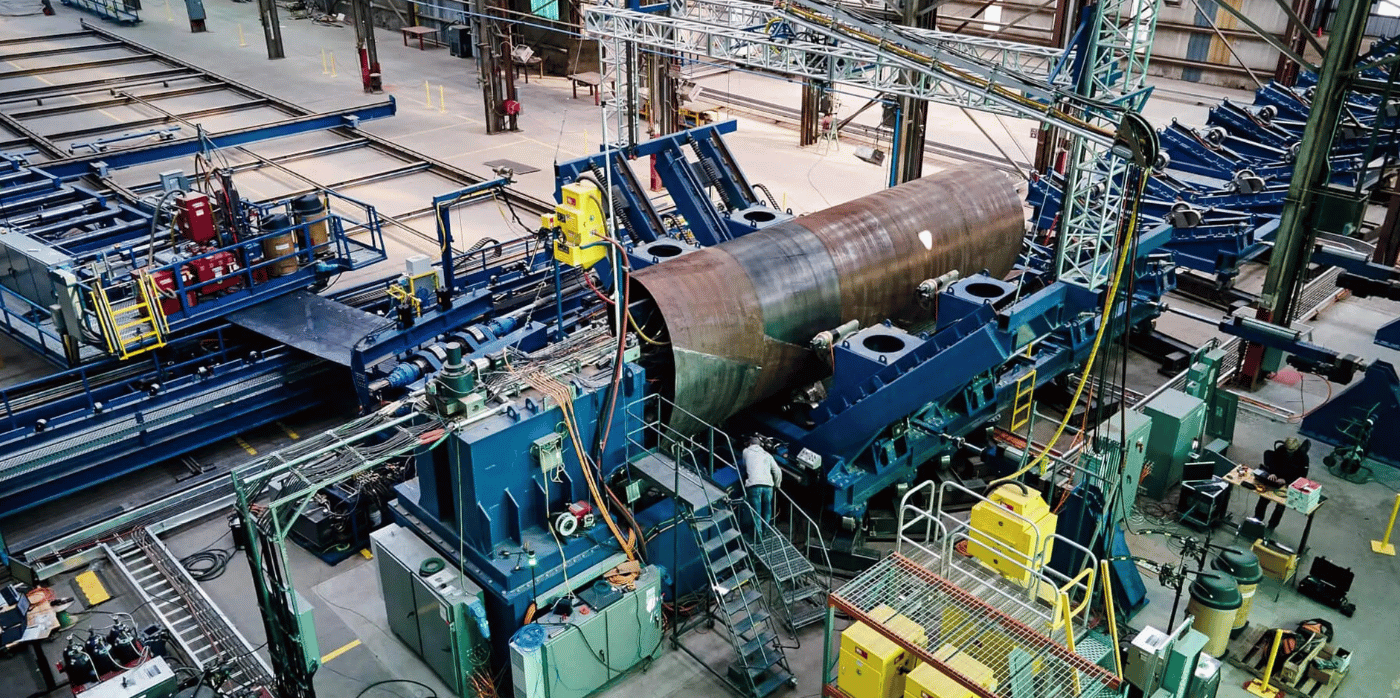

The company has devised a revolutionary manufacturing process that streamlines and cuts the cost of making turbine columns. In the company’s spiral welding process, which is a well-established technique used to create pipelines, large pieces of steel are fed into a machine, so they curve around into a spiral shape to form a turbine base. The process can be done quickly and continuously by one machine that completes the joining, rolling, fit-up, welding, and severing of a tower section.

With this method, it’s easy to vary the diameters and wall thicknesses, which means that wind towers can be built twice as tall as existing structures, enabling turbines with bigger blades that can also reach greater wind speeds further up in the sky. This means greater wind energy generation.

Keystone’s manufacturing facilities have a relatively small footprint, meaning they can be placed near proposed wind farms for on-site production. Developers therefore don’t need to worry about making long, expensive, and energy-intensive journeys to transport the massive pre-manufactured components required for larger-scale turbines. Instead, steel can be shipped flat, making for much easier transportation. This is particularly helpful for offshore farms, as a temporary manufacturing facility can be easily deployed on the coast, for the creation of tall, structurally optimised towers.

Wind is playing a key role in the green transition, and innovators are working to make it more efficient than ever. Springwise has also spotted small turbines for wind microgrids as well as this novel design that cuts the cost of wind power.

Written By: Archie Cox and Matilda Cox