Spotted: The global e-commerce packaging market is expected to reach a total market value of almost $100 billion (around €92 billion) by 2027, a huge increase from the 2020 value of $35 billion (around €32 billion). Many retailers recognise the high environmental costs such a volume of packaging incurs and are actively seeking recyclable, reusable, and compostable alternatives.

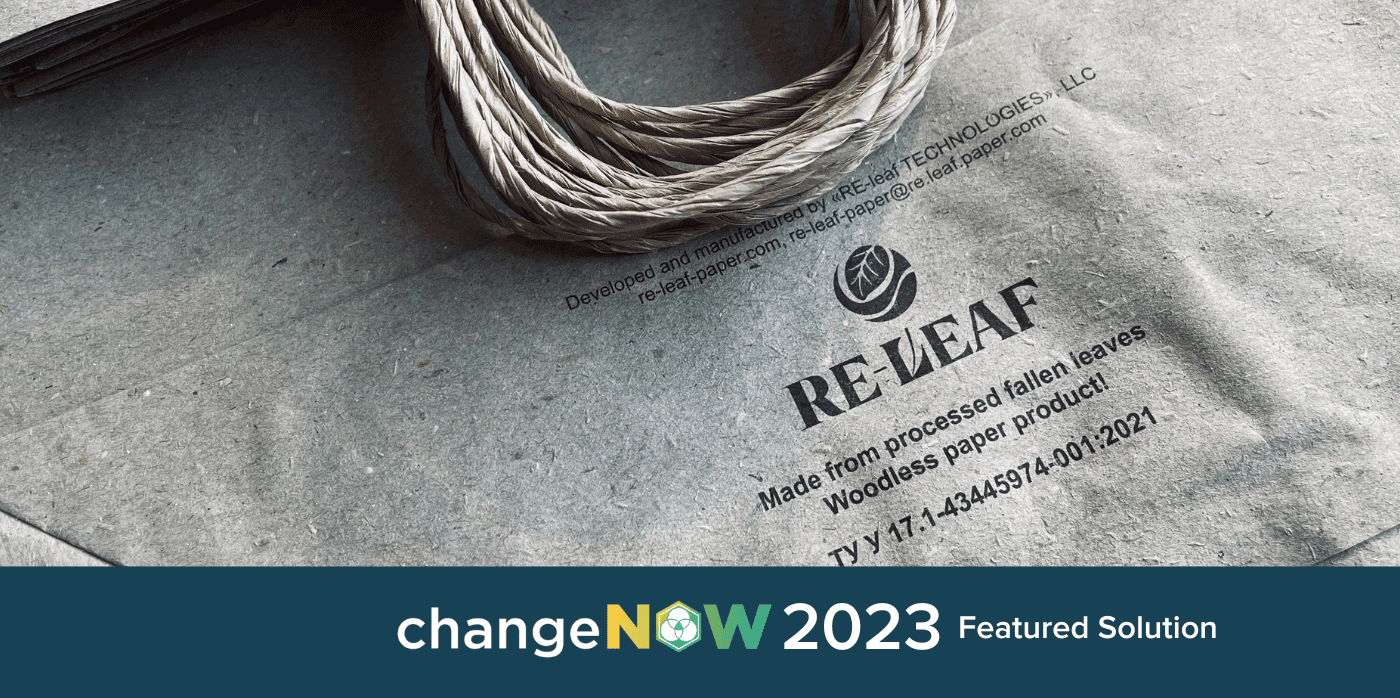

Paper is often considered a better option than plastic, yet some innovators are seeking ways to avoid deforestation by finding alternative sources of cellulose. One of the most successful so far is Valentyn Frechka and his company, Releaf. As a young student in Ukraine, Frechka spent years studying cellulose to find an alternative way of making paper. After testing fallen leaves, he began working on the technology that is now the base for Releaf, an international distributor of paper and paper packaging.

Releaf paper is made exclusively from collected biowaste and recycled fibre. The new manufacturing process uses 15 times less water than traditional paper production and reduces carbon emissions by 78 per cent. Much of the feedstock for the company’s products comes from urban street cleaning teams.

After collection, the leaves are cleaned, dried, and then turned into granules for long-term storage. The granules are stable, allowing the company to keep raw materials on hand for steady production cycles. Releaf produces paper ranging in weight from 70 to 300 grammes per square metre, along with a range of wrapping papers, bags, and e-commerce envelopes. Not only does the Releaf process relieve pressure on the world’s forests – it also helps city governments sustainably dispose of biowaste that would otherwise clog street drains and sewage pipes.

Other paper innovations Springwise has spotted recently include a single-use paper cup with integrated lid and a recyclable paper-based alternative to plastic bubble wrap.

Written By: Keely Khoury