Spotted: The International Energy Agency (IEA) says that in the net zero by 2050 scenario, direct air capture (DAC) needs to reach almost 60 megatonnes of CO2 every year by 2030. Currently, the 18 direct air capture plants in operation around the world are only sequestering 0.01 megatonnes of CO2. While experts consider 60 megatonnes of CO2 captured per year to be an attainable amount, additional large-scale plants are needed to reach that volume.

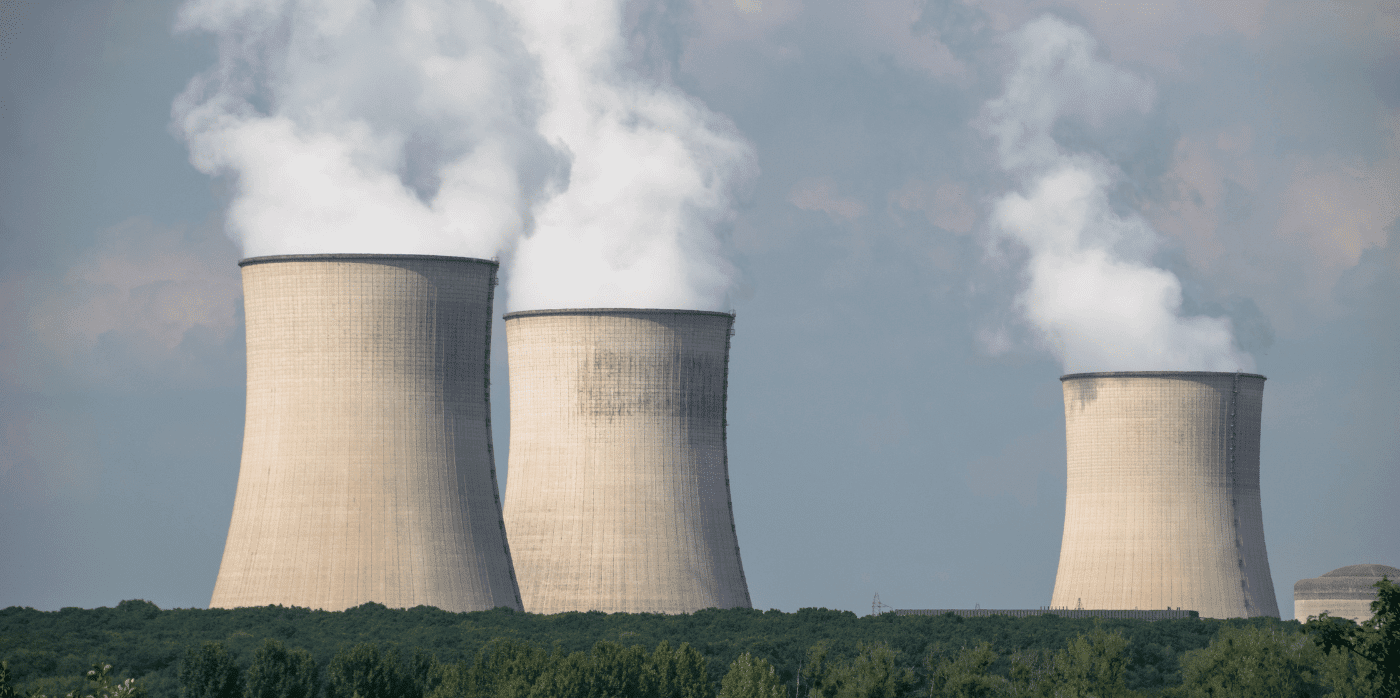

As well as building new plants, retrofitting old structures could be another way of reducing global emissions. German company NeoCarbon has built a system that integrates with existing cooling towers to capture carbon dioxide from the circulating air. As well as being ten times less expensive than a new carbon capture plant, NeoCarbon’s design could remove several billion tonnes of CO2 if it was applied to Europe’s current industrial manufacturing infrastructure.

NeoCarbon works with businesses to set up the carbon capture system and requires no upfront costs. Carbon dioxide is removed from the air as it circulates throughout the cooling towers, reducing companies’ emissions footprint without requiring any additional building expenses.

NeoCarbon transforms captured emissions into newly usable formats, including industrial chemicals and food-grade materials. Brands can buy removal credits as well as the captured carbon dioxide for use in their plants, and the NeoCarbon team says that their technology is mass market ready.

Sequestering carbon is an exciting area of growth, with Springwise spotting innovations improving ways emissions are captured, as well as expanding the uses of the waste carbon. In the fashion industry, one company is replacing traditional polyester fabrics with a net-positive version made from carbon dioxide. And another organisation is using geothermal energy to sustainably power its direct air capture systems.

Written By: Keely Khoury