Spotted: Insulation is important. In the UK, it’s estimated that 80 per cent of all the houses that will be in use in the year 2050, have already been built – but just 20 per cent will have been built to net zero standard. This means that 26 million UK homes will need to be retrofitted with improved insulation to reduce greenhouse gas emissions. And the situation is similar in other countries. In Switzerland, for instance, more than 1 million houses have no or insufficient insulation.

One of the key challenges when it comes to insulating homes is the trade-off builders need to make when choosing insulating material. Today, those installing insulation must compromise on either environmental impact, cost, or flammability. Now, however, Swiss startup FenX AG claims to have found a way to avoid this compromise.

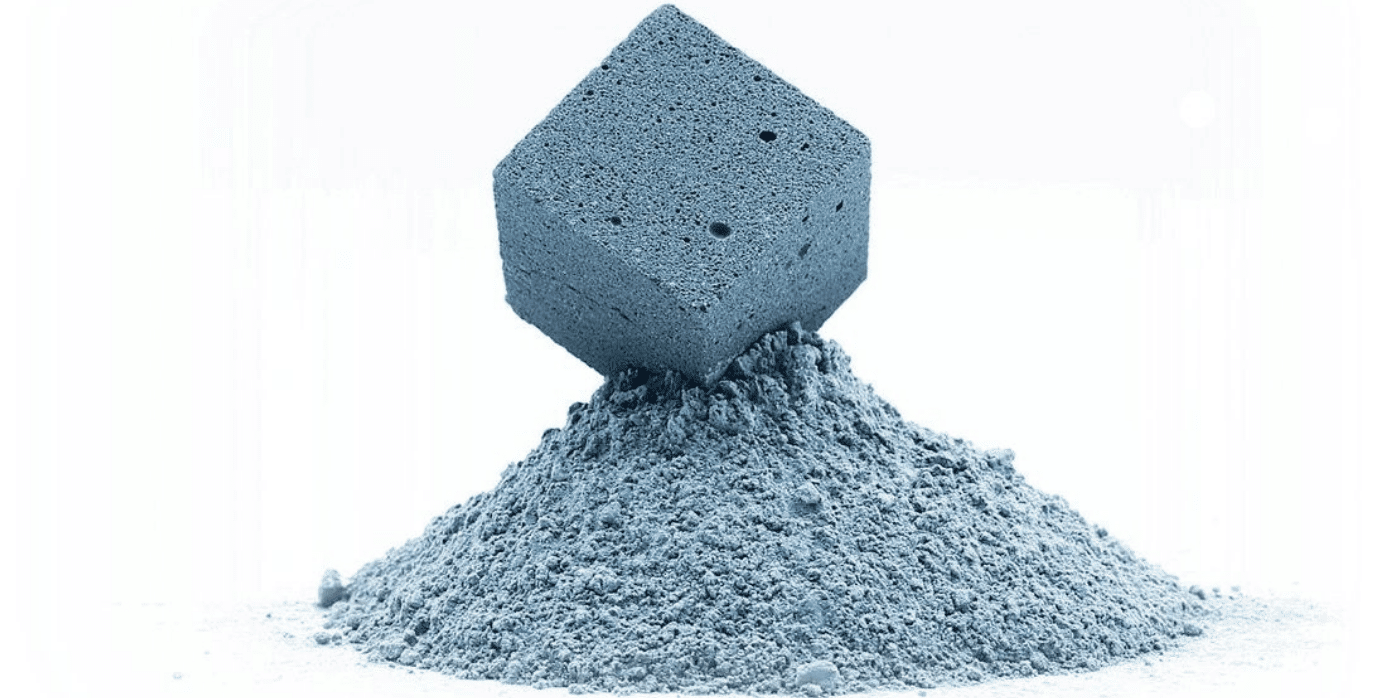

The startup’s solution is to create insulating foams from abundant mineral waste. Sourcing materials locally from a wide range of industrial waste streams and low-value natural resources, FenX uses its unique foaming technology to create insulating panels, bricks, and customised 3D-printed parts.

The composition of materials used as feedstock for this process meets all the necessary safety requirements for use in the building industry, and the finished foams are recyclable, non-flammable, 3D-printable, and high-performance. What is more, the manufacturing process for the materials results in very low carbon dioxide emissions.

In addition to its core insulation offering, FenX has partnered with ETH Zurich on a project that explores how foam 3D-printing can be used in conjunction with concrete casting to reduce concrete waste.

Springwise has spotted other recent innovations that reduce the environmental impact of buildings. These include building walls that can store carbon, a wood-based cooling foam that improves energy efficiency, and a startup that converts existing buildings to net zero using an innovative process.

Written By: Matthew Hempstead