When it comes to food, the world faces a two-pronged challenge. According to the Food and Agriculture Organisation of the United Nations, by 2050 we will need to produce 60 per cent more food to feed a world population of 9.3 billion. At the same time, food systems cause 25 to 30 per cent of global greenhouse gas emissions, and this figure rises to around one-third when we include all agricultural products.

We therefore not only need to produce more food – we also need to build a more sustainable food supply chain. As a result, by 2043, we are likely to produce food in a very different way. To shed some light on the topic, we asked some of the world’s leading futurists a simple question: what will we eat in 2043?

“The biggest impact on what we eat will be the personalisation of our diets,” explains food futurist Tony Hunter. “As we continue to explore our genetics and microbiome, we’ll come to understand just how individual we are in our nutritional responses to food,” he adds.

Hunter also argues that, “By 2043, we’ll have a range of new protein and other food products unlike anything we’ve ever seen before.” However, Christophe Pelletier, founder of The Food Futurist, is more skeptical in his assessment. According to him, “The future of food comes down to three boring but important aspects: price, the ability of food businesses to control costs, and the level of management skills of the business leadership.” In his assessment, “alternative protein producers come quite short on all three counts.”

So, will we be tucking into a whole host of exotic new proteins for our Wednesday lunch in 2043? Only time will tell. In the meantime, discover three innovations that represent the cutting edge of food innovation today.

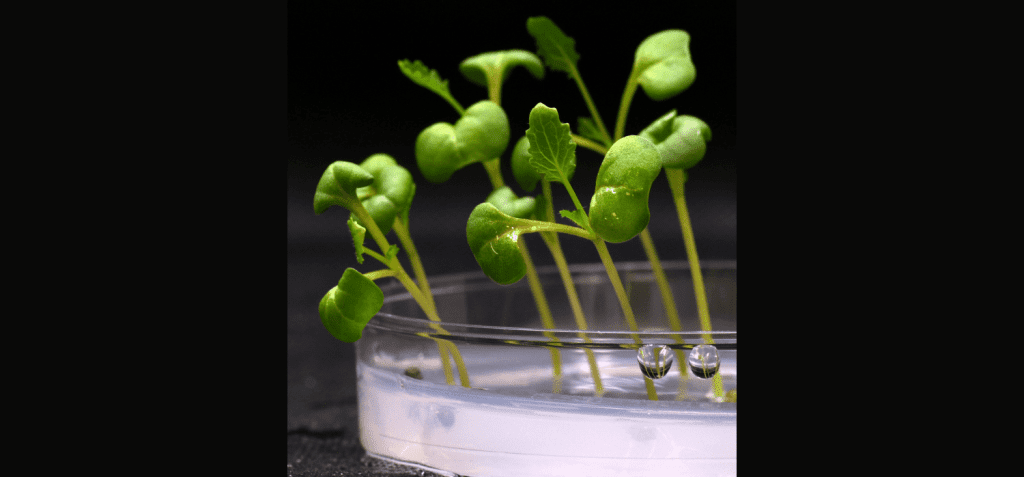

‘ARTIFICIAL PHOTOSYNTHESIS’ COULD BE THE FUTURE OF FOOD

Through photosynthesis, plants convert water, carbon dioxide, and energy from sunlight into sugars that they use to grow biomass. This process has been the basis of the food chain for millions of years, yet it is surprisingly inefficient. In fact, only about one per cent of the energy found in sunlight actually ends up in the plant. Now, scientists at the University of California Riverside have found a way to improve on mother nature by bypassing biological photosynthesis entirely. Read more

WORLD’S LARGEST VERTICAL MYCELIUM FARM SCALES UP PRODUCTION OF ALTERNATIVE BACON

It only takes MyForest Foods 12 days to grow an entire crop of mycelium, with the harvesting taking only a single day. Such rapid growth is made possible by the simulated forest inside Swersey Silos, the company’s newly expanded growing facilities in New York. The vertical farm contains seven growing rooms with just under two acres of total farm space. Read more

UPCYCLING BARLEY BYPRODUCTS INTO HIGH-PROTEIN FLOUR

Seoul-based food upcycling startup RE:Harvest has created a new flour alternative made from upcycled barley from the production of beer and sikhye – a traditional sweet Korean beverage. The company says that its powder is not only more sustainable than traditional flour, but that it also has a higher protein content. The company is currently working on scaling up its production so that it can meet the demand from both domestic and international customers – as well as expanding their byproduct sourcing. Read more

Want to discover more about what the world will look like in 2043? Download our free Future 2043 report which draws on the insights of 20 of the world’s leading futurists. For more innovations, head to the Springwise Innovation Library.