Spotted: Since their creation, fossil fuel vehicles have been a major contributor of greenhouse gas emissions. While we are beginning to lessen the environmental cost of road transport by travelling in fossil fuel-free cars, auto manufacturers still rely on fossil resources when building their products. And, with the Paris Agreement giving automakers until 2040 to produce net-zero greenhouse gas emissions in the entire value chain of vehicle production, this is an issue.

In a bid to resolve this, the Swedish steel manufacturer SSAB has harnessed new technology that leverages electricity and hydrogen to create fossil fuel-free steel. As steel is elemental to assembling cars and trucks, this innovation gives auto manufacturers a chance to fulfill the Paris Agreement and achieve net-zero emissions.

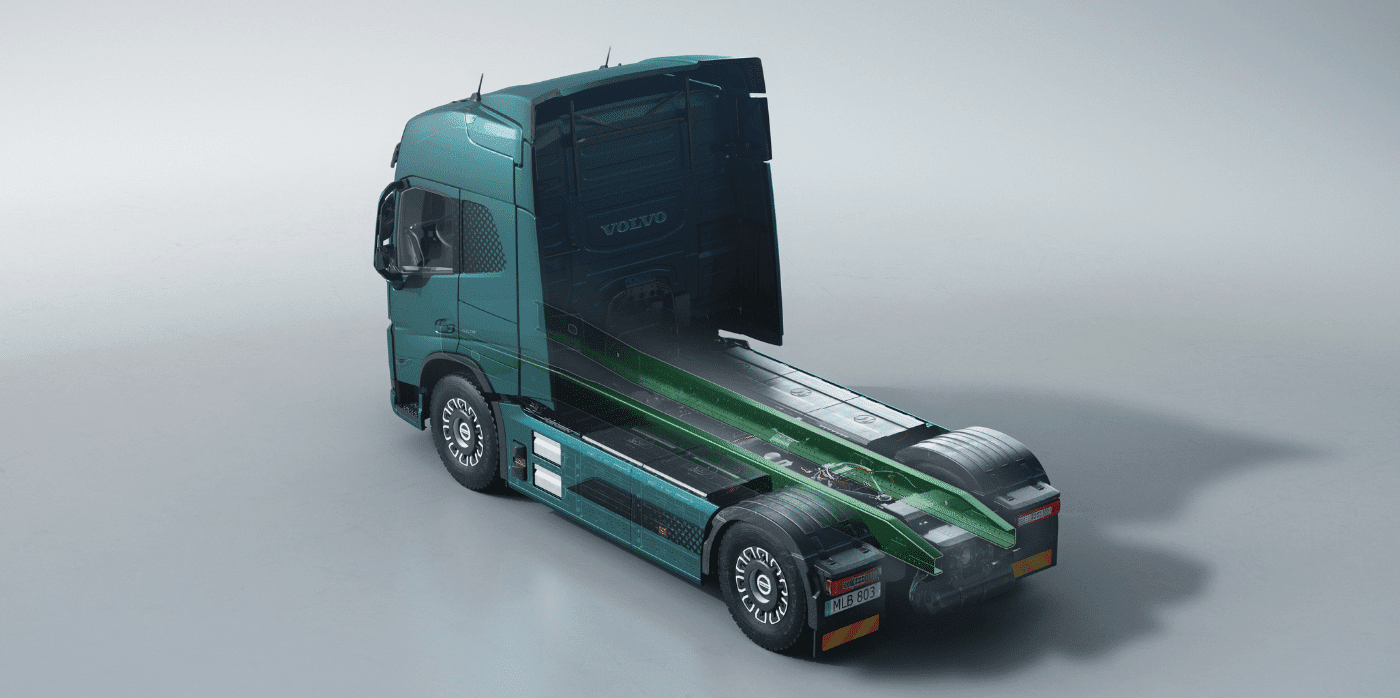

Showing its environmental commitment, Volvo Trucks has become the first truck manufacturer in the world to use fossil-free steel. The hydrogen-produced steel will be placed into the frame rails that form the backbone of Volvo’s electric trucks, where all the other main parts are mounted. Once the availability of fossil fuel-free steel increases, Volvo claims it will then be introduced in other parts of the truck.

“Our journey to net zero emissions includes both making our vehicles fossil-free in operation and over time fully replacing the material in our trucks with fossil-free and recycled alternatives,” says Jessica Sandström, Senior Vice President of Product Management at Volvo Trucks.

Volvo began their small-scale introduction of the SSAB steel in May 2022 and it became commercially available the following month, just nine months after the first fossil-free vehicle concept was unveiled.

Springwise has spotted other innovations seeking to decarbonise steel, such as the implementation of AI within steel and cement plants, and using green hydrogen to manufacture green steel.

Written By Georgia King