Spotted: By 2026, it is expected that the UK logistics sector will face a shortage of 400,000 workers. One solution to this problem is automation, and our 2022 European Logistics Occupier Survey found that 80 per cent of occupiers believe that warehouse robotics are the top technology disruptor to logistics supply chains. But does this mean that robots will replace human workers? Or will organisations opt for a hybrid approach to automation?

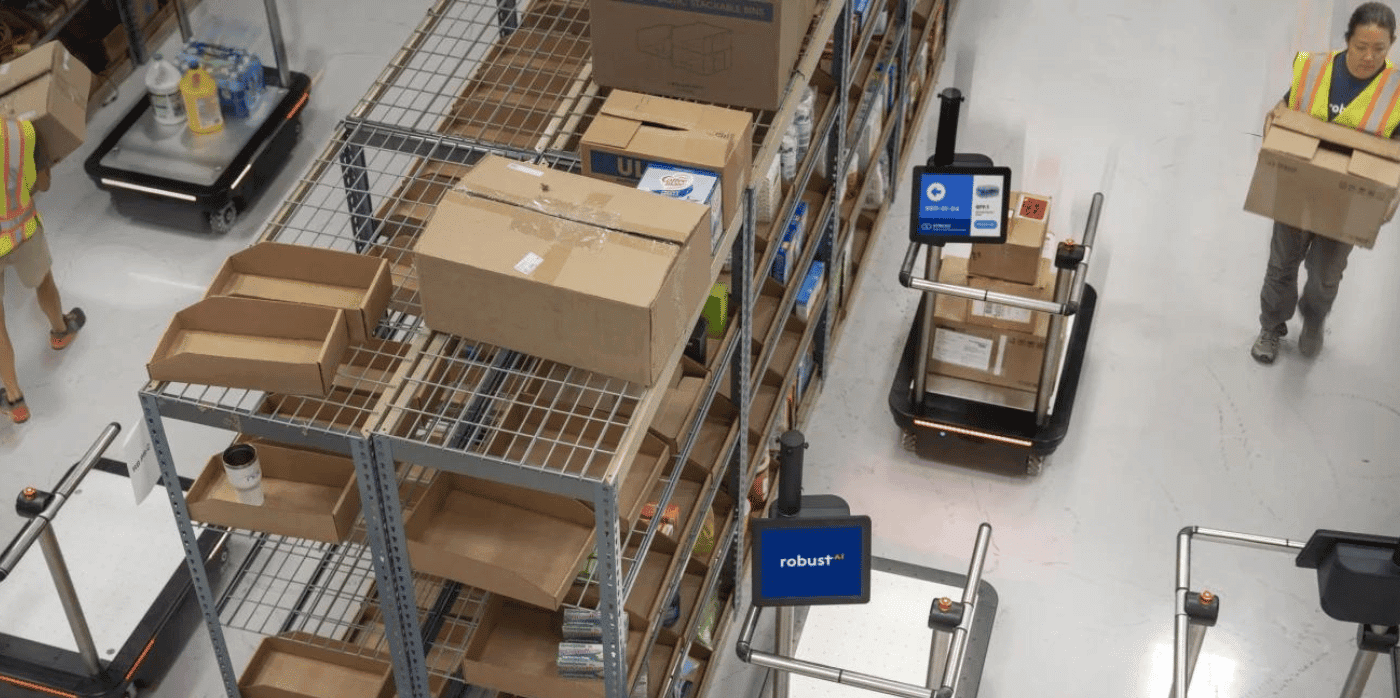

One startup that is firmly promoting the hybrid route is Robust.AI, a US-based company that develops robots that help human workers be more productive.

According to the company, many robotic solutions make people feel unsafe and unseen, which leads to inefficient operations. As a result, it has developed a Collaborative Mobile Robot (CMR) called ‘Carter’. This CMR, the startup’s first hardware product, is designed to not only work near workers, but with them. The robots, which are essentially autonomous warehouse carts, move with and respond to human workers – like a ‘dance partner’ – and can be easily taken over manually by a worker grabbing the handlebar. The idea is that the robots will take care of laborious and repetitive tasks, such as transporting objects, leaving human workers to focus on high-value activities such as picking and packing.

Supporting Robust.AI’s hardware is its software suite ‘Grace’. This, the company claims, allows facilities managers to introduce automation quickly without changing their existing environment. To set up Grace, employees walk through the warehouse using the camera on a phone or tablet to map the environment. This creates a digital model of the facility, which can be used to set up workflows, all through a standard web browser. For example, a facilities manager can set up a virtual conveyor belt between two points in a warehouse using the robots.

The Grace software is also installed on the Carter robots, allowing them to perceive and track people, locations, and objects. The robots then feed their perceptions back to fleet intelligence to optimise the system.

Springwise has spotted many other ways robots are being used, including to clean ships and make deliveries.

Written By: Matthew Hempstead