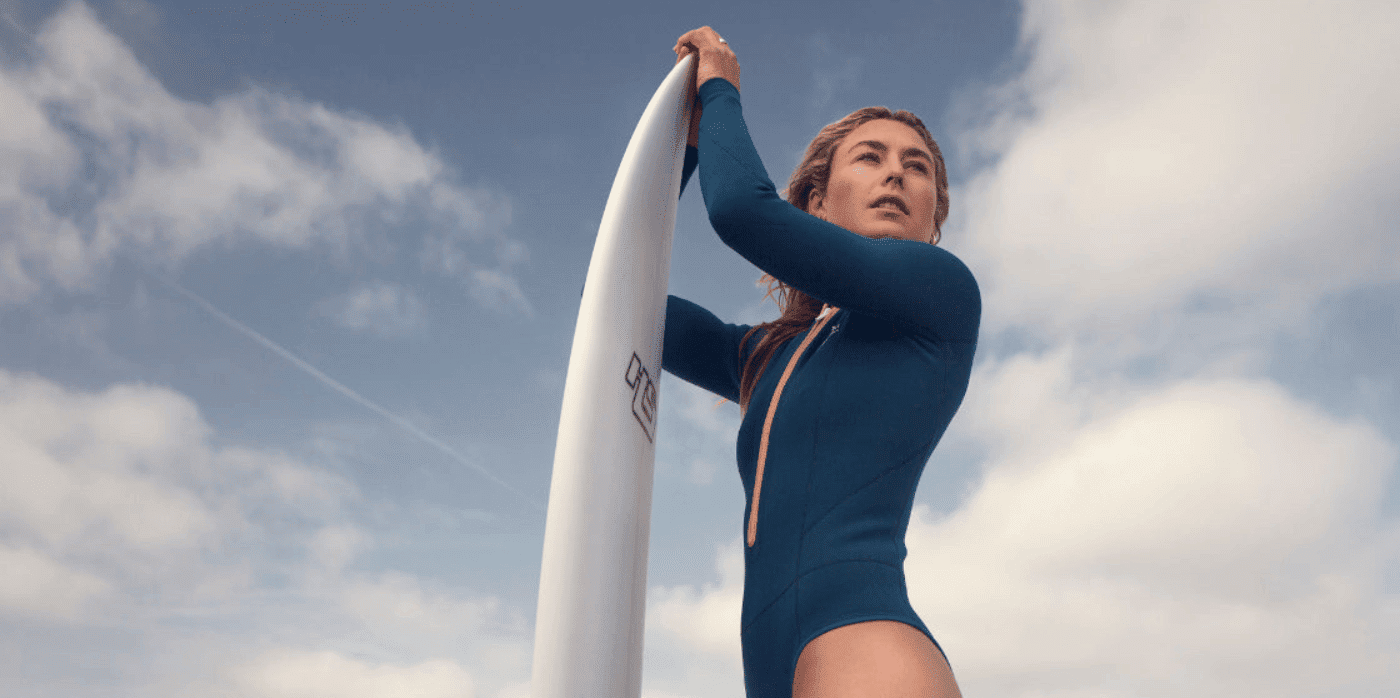

One thing we often hear when we talk to innovators and corporates alike, is the importance of partnerships as we pursue our climate goals. We take a closer look at this trend and talk to Jennifer Droguett, Creative Director of Anciela, a London-based conscious womenswear label.

Founded in 2019, Anciela is a homage to Jennifer’s South American heritage. Taking inspiration from art, literature, and historical costumes, the brand offers re-worked tailoring and eccentric Ready-To-Wear, interwoven with a hint of the magical. The brand has been featured in Vogue, Harper’s Bazaar, L’officiel, and Forbes, among other independent publications.

Jennifer has seen the fashion industry from the vantage point of both established brands and her own startup. She spent 10 years at the start of her career working in brands like Viktor&Rolf and House of Holland. However, she took the plunge and started her own brand, after growing frustrated with the way big fashion works. She shares her views on the importance of partnerships and the ability of small producers to drive positive change by experimenting and taking risks.

A discussion with Jennifer droguett

“After four years I started feeling: wow, you don’t have a lot of influence,” she explained when she sat down with Springwise. Often, Jennifer highlights, you’re just a “small piece” of a much bigger machine. “I think what they don’t teach you at uni, it’s just this system – how fashion operates – is very out of necessity sometimes, it’s not really thinking about ‘how can this work for everyone?’”

“I did think: we need to do better. That really bothered me. Even if you have very little resources, or if you’re a massive giant – why aren’t we doing more? Why are we wasting things? It didn’t feel like everyone was on the same wavelength of: reduce, reuse, recycle. And sometimes with the choice of materials, people didn’t think, hang on a minute, this is super plastic, super oil-based, or polluting.”

Materials matter

By contrast, Jennifer founded Anciela with sustainability as a core principle, and the brand works with low-impact natural materials such as Tencel, Hemp, Linen, wool, silk, and organic or recycled cotton.

“The first principle when you have no resources is to work with what is already there, the famous deadstock that we all know. So then it’s just going to the warehouses and seeing what’s there,” Jennifer explained when asked about material choice.

Offcuts were how Jennifer started, but as Anciela developed she was drawn to new experiments, and she ageed to collaborate with freelance textile designer Alice Timms. “At the beginning, we all wanted to try recycled yarns – recycled plastic was all the rage,” she explains. “Everyone was using NewLife yarns [made from recycled plastic bottles] for very nylon-y, outerwear, sporty things. But I was like, could we use it for something else?” That ‘something else’ was a jacquard weave (a complex woven fabric) made from NewLife yarns instead of silk.

The next step was embracing more natural fibres like wool, hemp, and linen, while maintaining the focus on circularity. Jennifer added a compost bin to her studio that mixed food and textile waste – a move that proved to be extremely successful: “I was shocked, the worms loved the hemp and linen, it was gone in 12 or 15 days,” she explained. This was followed up with a weave made from recycled wool yarns, again in collaboration with Alice Timms.

Material choice is important for Anciela, but it is not the full story. Developing patterns that make the best use of material plays an important role, as does careful, low-volume ordering from local mills for the small portion of the collection that uses new fabrics. “We’ve been really strict on my collection plan, understanding exactly what I need,” Jennifer explains. You can’t be ordering extra ‘just in case’.

“That’s why I was transitioning to naturals, because that’s already so thin and small that [any offcuts are] perfect for the compost. So, all of that production waste can just go directly to the compost and that’s really beautiful as well.”

Collaborative efforts

With all these developments, Jennifer emphasises the freedom enjoyed by smaller producers: “As a small player you can do that… I can have my experiments.” This touches on an important question: how can small players like Anciela – which does everything made-to-order and most things in-house – have an impact in a market dominated by large, high-volume companies?

“As a small player, you make all the decisions so there’s no excuse not to try anything. We have that advantage as a small business that you can pivot… When you keep things small, there is no risk, you’re not making thousands of garments,” she explains. And that’s something big companies can tap into through partnerships.

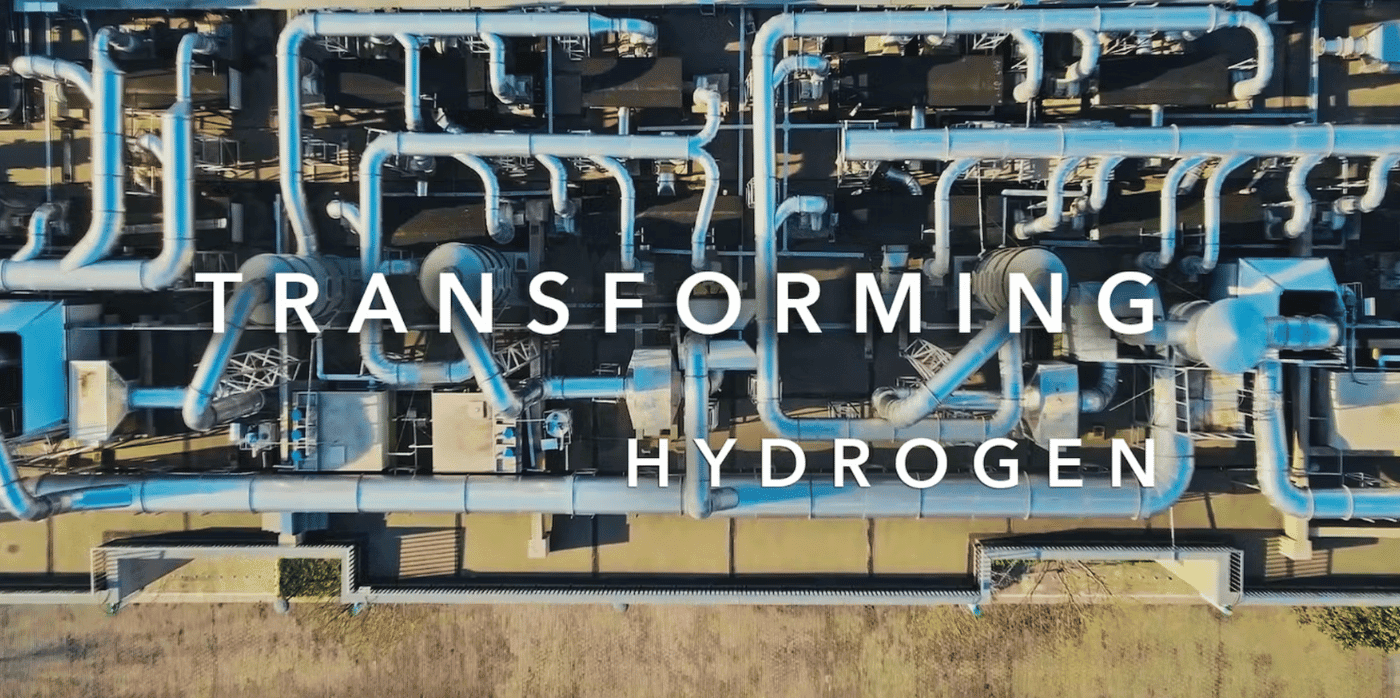

Jennifer highlights her collaboration with Tencel Luxe – a luxury fabric made by multinational chemical company Lenzing. Normally, the company works with big brands that buy in large volumes. But Jennifer discovered that they too had an appetite for experimentation: “They wanted to help small designers make more experimental things.”

To Jennifer that is the value to big companies of partnerships, which she believes are the way the world is going: “We’re all people, we all want to do something, whether you work for a big or a small company.”

What can big brands do differently?

Beyond taking a risk and working with smaller, more agile companies, Jennifer highlights that the bigger fashion labels need a culture shift if they really want to commit to sustainable change.

“Don’t overproduce, there’s no need for that. It’s better to really put out there what needs to be out there,” says Jennifer. “Of course, it’s not as simple as it sounds – I understand because I’ve worked for bigger brands. I understand the machine – those companies are machines. But I feel there needs to be a shift at a business model level.”

“We have to be more mindful of what we’re putting out there and prioritise the quality of our supply chain, the quality of the life of the people in that supply chain and tracing all the way back.”

True sustainability goes beyond environmental concerns. Jennifer stresses: “We talk about climate change but it is about people, it is about looking after each other as people, from the farmers onward. You hear so many horror stories from every single step of the supply chain…When we can relate personally to a cause, the changes can happen very quickly. That’s the shift. Climate change is about people and it’s going to affect us all, whether we like it or not.”

Are you looking for more good news on individuals making positive change across industry? Take a look at the Springwise database for more inspiration, and make sure you’re subscribed to our monthly newsletter so you don’t miss the first look at our next Planet Champion.

Words: Matthew Hempstead and Matilda Cox