AI and remote sensing technology for managing water risk

Spotted: By 2030, the world’s communal demand for fresh water is expected to outstrip supply by 40 per cent. How to avert this crisis is a question many innovators, researchers, and agencies are working to answer. And sustainable management of the water that is currently available is a crucial aspect of the global solution.

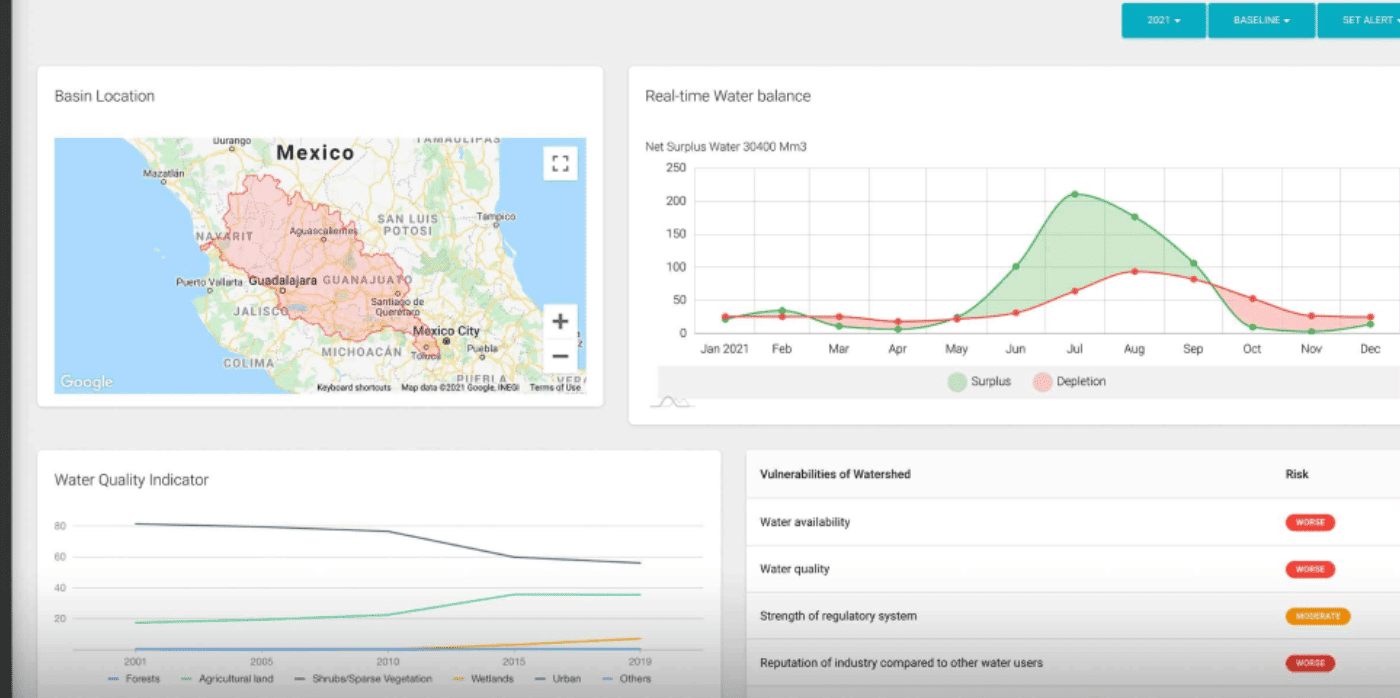

Understanding the health of the world’s bodies of water, along with current and potential future risks is vital, and San Francisco-based technology company Waterplan has created a platform that uses remote sensing and artificial intelligence (AI) to track, analyse, and mitigate the risk to global water supplies.

The platform helps organisations of any kind plan for the future by protecting water supplies now. The highly detailed reports include data from regulatory reviews, watershed authorities, industry analysis, scientific research, and more, with information presented in easily navigable formats. Clients view data by site and can see at a glance which areas need risk mitigation first.

The reports are structured in a way that makes them usable for investors, and client input helps shape what areas the AI tracks. Sustainability managers use the platform to track progress against targets and measure the efficacy of various interventions. Operations managers can use the platform to maintain peak productivity across all processes and locations, as well as predict adjustments needed based on changing conditions.

With the need for robust data continual, Waterplan recently closed an oversubscribed series A financing round that raised $11 million (around €10 million).

Cleaning polluted water is one way to improve the quantity of supply, and examples from Springwise’s archive include a membrane that generates electricity while cleaning wastewater and a modular sewage treatment plant that fits inside a shipping container.

Written By: Keely Khoury