Vaccine printers expanding access to immunisation

Spotted: During the COVID-19 pandemic, millions of children missed out on regularly scheduled immunisations, which resulted in local outbreaks of diseases such as measles, polio, and yellow fever that have, for the most part, been kept under control worldwide for many years.

As communities adjust to life post-pandemic and make plans for the ongoing management of infectious diseases, innovators are seeking solutions to some of the complex challenges presented by the COVID-19 outbreak. One of the most difficult aspects of distributing vaccines during the pandemic was keeping them at the appropriate temperature while shipping and storing them in locations with irregular access to electricity and cold storage.

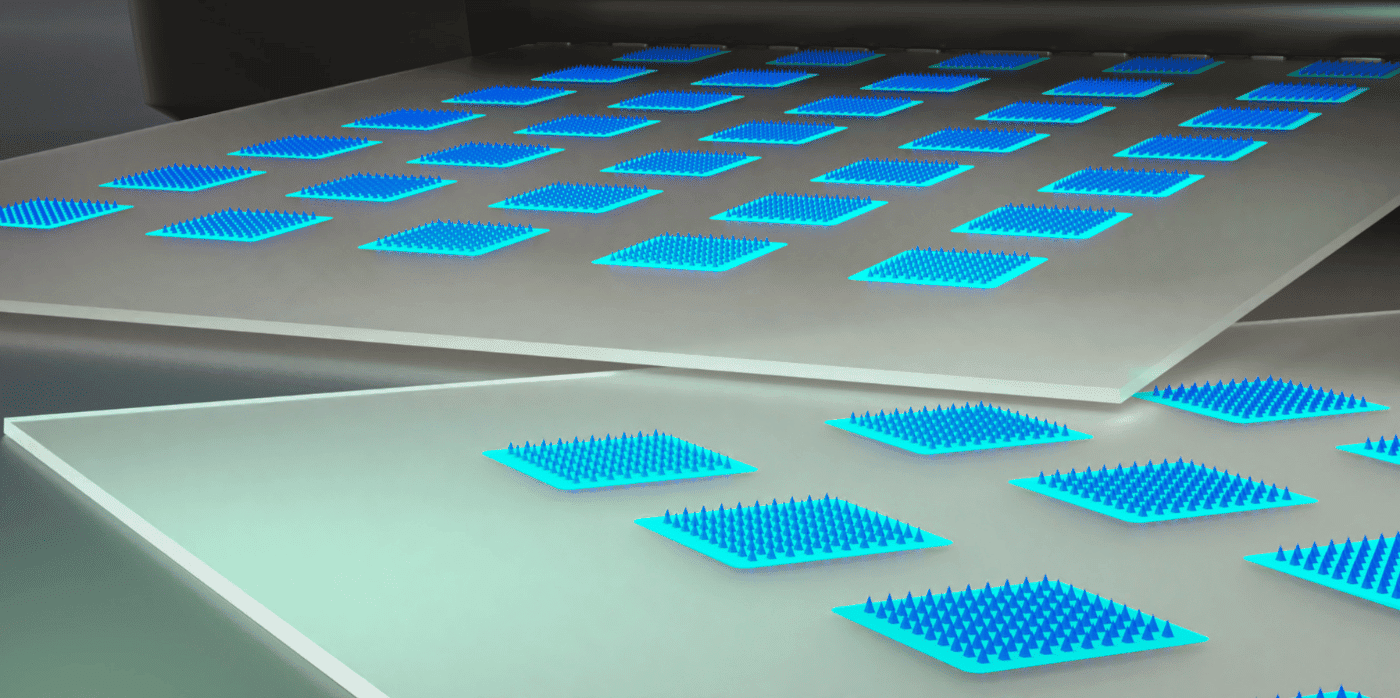

A team of Massachusetts Institute of Technology (MIT) researchers decided to try making vaccines that could be stored at room temperature as a way of mitigating that hazard. What they created is a mobile printer that produces thumbprint-sized vaccine patches that can be stored at room temperature. The printer easily fits on a tabletop, and the patches can be self-applied. Eliminating the need for syringes and application by healthcare professionals immediately increases the accessibility of the medicine.

Each patch contains hundreds of microneedles filled with the vaccine. When the patch is applied to the skin, the microneedles dissolve underneath, releasing the vaccine into the body. Lipid nanoparticles hold the vaccine, which is what makes it possible to store the medicine for many months at room temperature.

The prototype printer produces around 100 patches every 48 hours, and the scientists are already working on improving that speed and capacity, as well as adapting and developing the process for use with various vaccines.

Other innovations that Springwise has spotted that focus on vaccine accessibility include a new storage method that makes it possible to keep vaccines at room temperature and a solar-powered portable refrigerator that healthcare workers can carry on a bicycle.

Written By: Keely Khoury