Five innovative startups with female founders

How many startups are founded by women? Although there are signs of progress, the answer remains ‘too few.’

According to data compiler Statista, the proportion of global startups with at least one female founder increased from 10 per cent in 2009 to 20 per cent in 2019. This long-term trend may be promising, but 20 per cent is still a strikingly low figure – significantly lower than the 32 per cent of S&P 500 board seats that are held by women, and far short of the 49.7 per cent of the world population that is female.

The headline figure also doesn’t tell the full story. As a worldwide statistic it masks significant regional variation, and it also smooths over imbalances between sectors. For example, one study of US companies founded between 2016 and 2021 showed that women make up 24 per cent of founders in the education sector, but only 10 per cent in fintech and energy, and 9 per cent in hardware.

As Springwise reported last year, female founders are also getting short-changed when it comes to the amount of early-stage capital they receive compared to their male counterparts. And the proportion of venture capital funding allocated to startups with female founders has remained flat since 2011, even as the proportion of female-founded companies has increased.

At Springwise we regularly see inspiring work from female founders. To celebrate International Women’s Day, discover five of the most exciting innovations from female-founded startups.

There is perhaps no better place to start than Mukuru Clean Stoves, winner of the ‘Clean our Air’ category at The Earthshot Prize in 2022. Led by Kenya-born Charlot Magayi, the startup uses recycled materials to manufacture safe and clean cookstoves for low-income families in East Africa. One of the key benefits of the stoves is that they tackle household air pollution, which causes a range of health issues from strokes and heart disease to lung cancer. Magayi became aware of the issue in 2012, while she was researching safer stove designs after her daughter was burned by an overturned cookstove. Inspired to make a difference, she founded Mukuru Clean Stoves to make cleaner cooking affordable for all. Read more

Countries across the globe are producing millions of metric tonnes of single-use plastic waste each year. And even the cardboard and paper containers that are increasingly common are not truly sustainable, as most contain a plastic coating to prevent leaks. To tackle this problem, Singapore-based startup Alterpacks has developed a line of compostable packaging made from malt and barley grain waste from beer brewing. Rather than relying on a coating, the whole container is leakproof, microwaveable, washable, and home-compostable. Alterpacks was founded by Karen Cheah. After 20 successful years working for entertainment companies, Cheah embarked on a change of career, founding the startup after completing a Master’s at Singapore Management University. Read more

French startup Uptrade is on a mission to solve the fashion industry’s fabric waste problem. The company has developed a matchmaking platform that connects those with unused fabric to sell with those looking to buy. For buyers, Uptrade curates a selection of ‘sleeping stocks’ based on quantity, quality, and origin. Traceability is core to the platform, with the ‘Uptrade – Saved fabric’ label guaranteeing both the origin of a fabric and the sustainable approach of the seller. Uptrade also negotiates a price that is fair to both parties. For sellers, Uptrade takes care of all the logistics. All the seller has to do is prepare the parcel and let Uptrade know its weight and dimensions. Further instructions are then provided with the purchase order, with shipping costs borne by the buyer. Uptrade was founded by female duo Eleonore Rothley Lafon and Charlotte Billot. Billot had been working on reusing end-of-life products for 10 years before she met Lafon, who had experience with a social enterprise in Cambodia focused on environmental protection and natural fibre production. Together, the pair developed the idea of Uptrade. Read more

The long-term economic success of many European countries is threatened by a persistent talent gap. And in hi-tech sectors such as artificial intelligence, the problem is particularly acute. Faced with the challenge of filling vital positions, it is more important than ever that companies can access the best talent from around the world. But relocating employees and hiring across borders comes with administrative and logistical challenges. This is where German startup Localyze comes in. Part all-in-one platform, part personalised support service, Localyze takes care of the admin-heavy tasks involved with finding the best global talent. The company claims that HR teams can hand over cases involving global mobility to its experts in as little as two minutes. They can then easily keep tabs on the status of each case through an easy-to-use dashboard that notifies users when they need to act. Localyze was founded by three women: Hanna Marie Asmussen, Lisa Dahlke, and Franzi Low. The idea for the startup came from their shared experiences of employee relocation and its many challenges. Read more

A large proportion of the world’s arable land is already degraded by the effects of climate change, pollution, and salinisation, and this is set to get worse over time. At the same time, the agricultural industry spends a huge amount of money on fertilisers and other soil treatments. Now, Argentinian startup Puna Bio is developing a novel all-natural solution for improving crop yields using extremophile organisms – microbes evolved to thrive in extreme environments. Puna Bio co-founder Elisa Bertini scoured locations including Utah’s Great Salt Lake and South America’s high desert, known in Argentina as La Puna, for organisms that thrive in harsh environments like active volcanoes, saline wetlands, and desert soils. The extremophiles that live in these locations have evolved to live with a low amount of nutrients, such as nitrogen or phosphorus, making them very efficient. When transported to other soils, including those that are very degraded, these organisms thrive and improve yield. Bertini founded Puna Bio with two female co-founders, Caroline Belfiore and María Eugenia Farías, along with their male colleague Franco Martínez Levis. Read more

Written By: Matthew Hempstead

For more innovations, head to the Springwise Innovation Library.

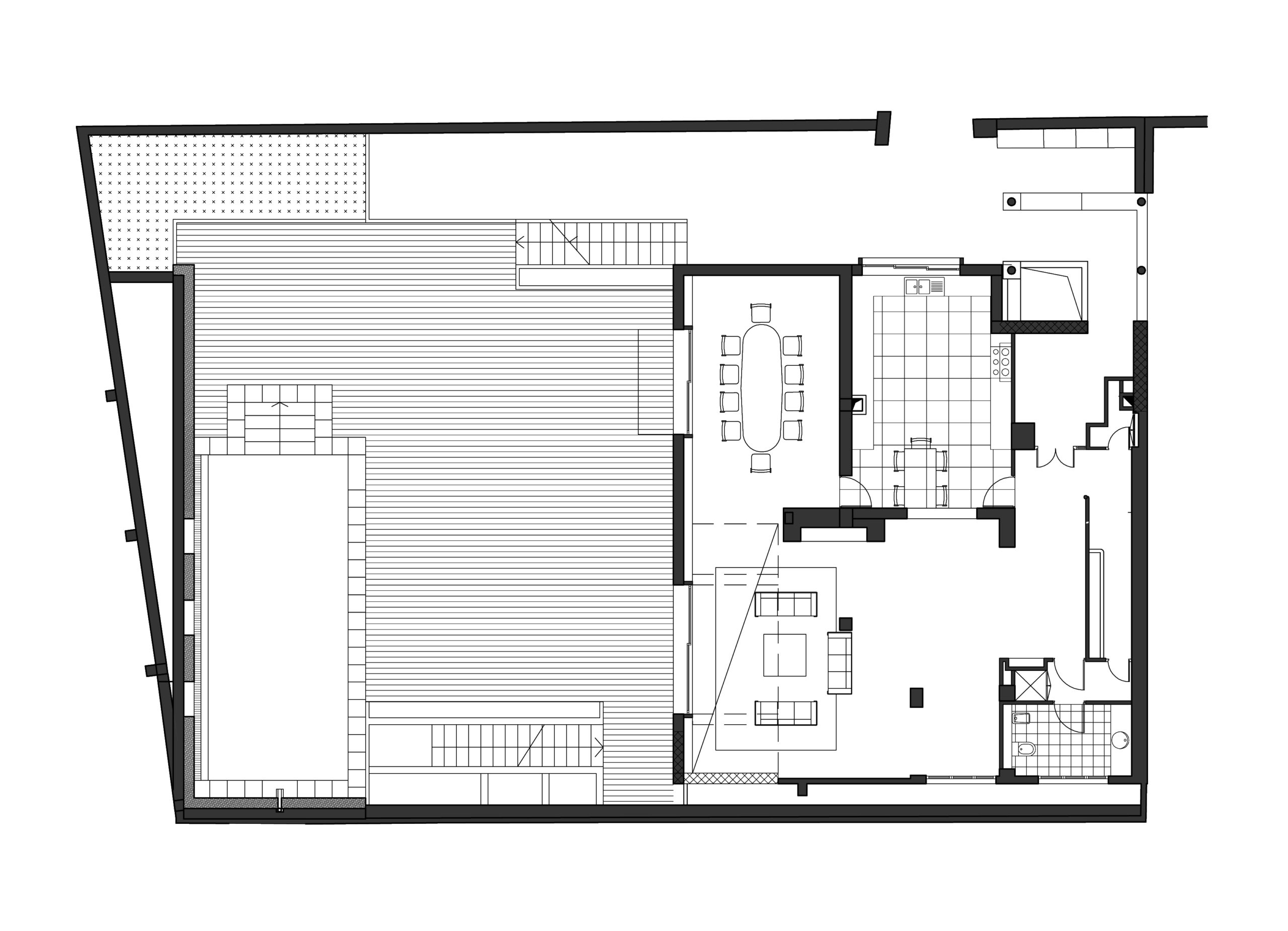

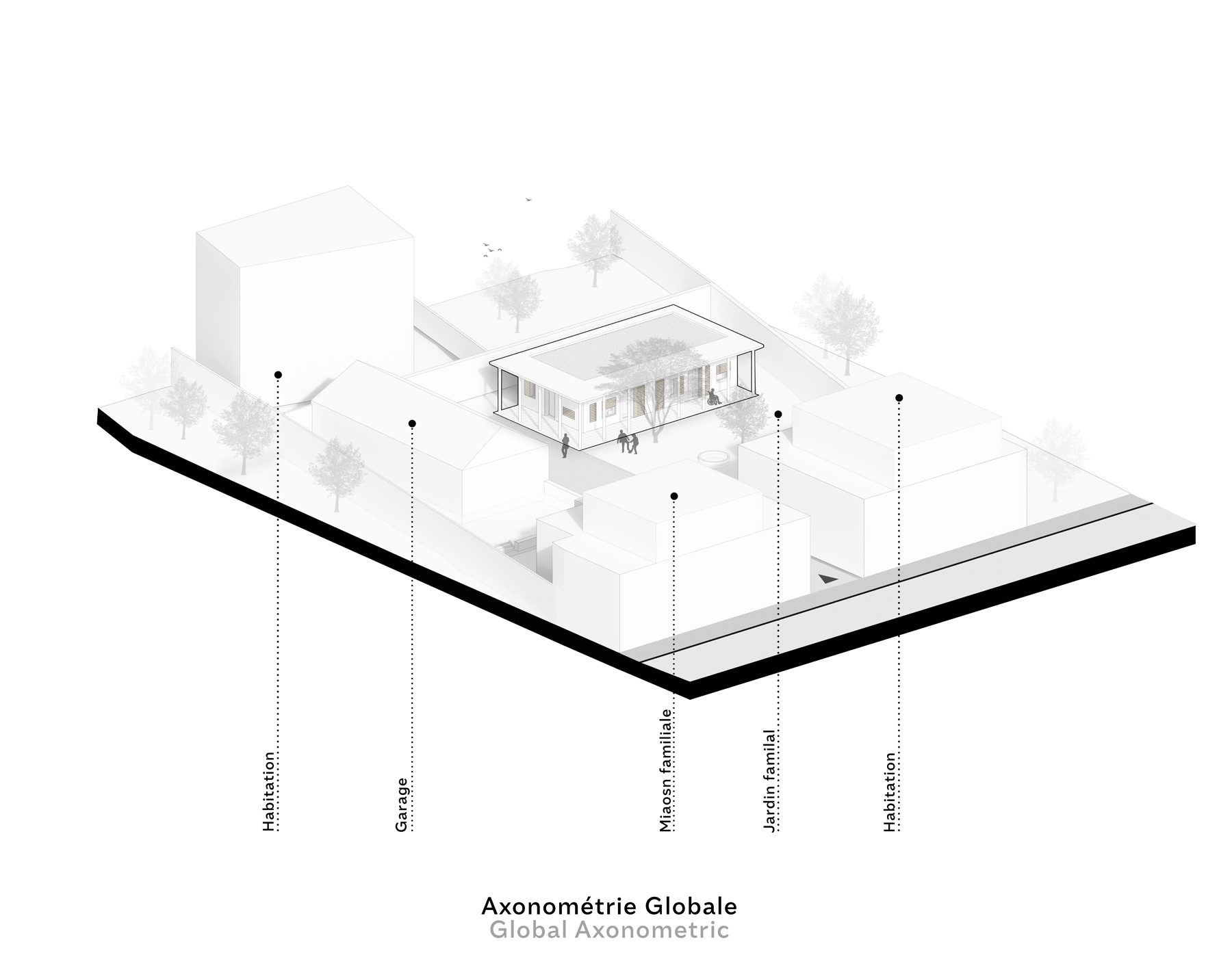

In this highly accessible house that was designed for two elderly parents in Tipaza, three factors guided the design process: privacy, weather conditions and activity, which reflected on the building envelope, building layout and building orientation. The design of the openings achieved the required level of privacy for Algerian culture, while opening up the house to the surrounding garden for natural ventilation, sunlight and views, taking in consideration the challenging weather conditions of the area.

In this highly accessible house that was designed for two elderly parents in Tipaza, three factors guided the design process: privacy, weather conditions and activity, which reflected on the building envelope, building layout and building orientation. The design of the openings achieved the required level of privacy for Algerian culture, while opening up the house to the surrounding garden for natural ventilation, sunlight and views, taking in consideration the challenging weather conditions of the area.