Three innovations for the future of transport

The most obvious recent development in transport has been the ongoing shift in how we power our vehicles. And although the roll-out of electric vehicles (EVs) has been uneven – with China, the US, and Europe leading the way – significant progress has been made. In fact, in 2022, the world passed a key milestone, with EVs making up 10 per cent of all new cars sold. EVs are also one of the few areas where the International Energy Agency deems the world to be on track to meet its net zero 2050 scenario.

However, although there remains some way to go before all cars on the road are electric – if indeed that point is ever reached – EVs are in some ways old news. As Susan Cox-Smith, a partner and director at Changeist puts it: “The tipping point for electric vehicles has already been hit.”

For our Future 2043 Report, we took a much longer view when asking the world’s leading futurists how we will move around in the year 2043. Will the idea of the personal or family car still be around in 20 years’ time – even if we wean our vehicles off fossil fuels? Well, in Cox-Smith’s view: “full ownership will probably decline as micro-rentals and shared vehicles become the norm.”

So if the car owner is out, what about the driver? Will autonomous vehicles – long predicted by technologists – be accepted by the mainstream? And what will this mean for our legal and ethical systems?

“Ethically and psychologically, I see driverless cars as a major step towards redefining a shift in social responsibility, that will likely have repercussions for other industries from medicine to food,” explains creative technologist Jude Pullen.

How we will move around in the future is one of the big unanswered questions. But, in the meantime, discover three innovations that might provide us with a clue. Will we even do away with roads Back to the Future style?

SOLAR-POWERED TUK-TUKS COULD BE COMING TO A CITY NEAR YOU

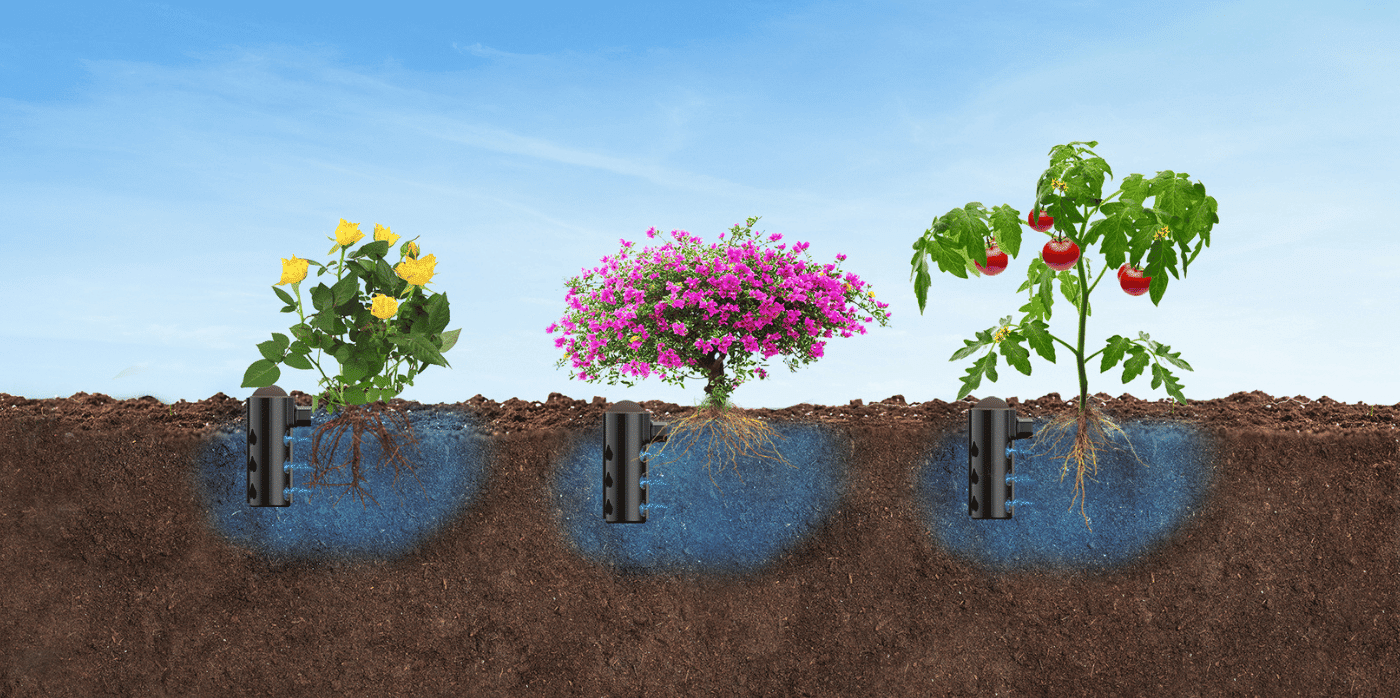

Increasingly, those interested in city planning and energy saving have been pointing out that it just doesn’t make sense to transport people or smaller amounts of goods around urban areas in traditional vehicles – even EVs. Cars are large, heavy, and energy-intensive. Startup Infinite Mobility has developed an alternative – a solar-powered tuk-tuk designed for last-mile deliveries, or to efficiently carry just one or two people. Read more

STARTUP PLANS TO CREATE A WORLDWIDE NETWORK OF FLYING TAXI AND CARGO DRONE HUBS

The urban air mobility market is on the up, with forecasts predicting it could reach $1 trillion in the next 20 years. From flying taxis to delivery drones, emerging technologies have the potential to transform how people and goods move around cities, by-passing congested road transport systems by – literally – rising above them. To date, most of the investment has gone into the development of flying vehicles themselves. But a lack of ground infrastructure remains a limitation on the mass roll-out of these vehicles. To fill this infrastructure gap, UK-based Urban-Air Port intends to build 200 advanced air transport hubs – called ‘vertiports’ – around the world. Read more

ELECTRIC FLYING CAR COMPLETES PUBLIC EXHIBITION FLIGHT

Flying cars are becoming a reality. China’s XPENG mobility technology experts recently completed a public flight of the electric flying car XPENG X2 at an event at the Dubai World Trade Centre. The zero-emission vehicle is a two-seater car that uses vertical lift-off and landing to transition from road travel to air. Designed specifically for the complexities of urban driving, the X2 flies at low altitude and can be driven manually or autonomously. Read more

Want to discover more about what the world will look like in 2043? Download our free Future 2043 report which draws on the insights of 20 of the world’s leading futurists. For more innovations, head to the Springwise Innovation Library.