BVN and UTS rethink air conditioning with 3D-printed “breathing” system

Australian architecture practice BVN and the University of Technology Sydney have created a low-carbon, 3D-printed system that “breathes” like frog skin.

Named Systems Reef 2, the invention was made of recycled plastic 3D printed into a computationally optimised design that BVN said has 90 per cent less embodied carbon than a standard air-conditioning system.

The system also uses less operational energy because the air flows more easily around the organically shaped, branching tubing, with no corners to get stuck in.

The invention was designed to tackle the many deficiencies the architecture studio identified with air conditioning, a technology that BVN co-CEO Ninotschka Titchkosky describes as not having changed much since its invention in the early 1900s and having been “largely designed for manufacturing processes as opposed to human comfort”.

Air conditioning systems are typically made from steel sheets, which the BVN and UTS team’s analysis showed results in high embodied carbon and the use of much more material than is necessary. The systems also waste energy because they are structurally inefficient and difficult to change after installation.

“At the moment, the systems that we have, they’re really inflexible, they’re not particularly great for human comfort, they’re really expensive to change and they really limit the way we want to occupy buildings now in the 21st century, which is much more adaptive and agile,” Titchkosky told Dezeen.

A key difference with Systems Reef 2 is that it’s “designed for air”, removing one of the key sources of inefficiency in existing systems: right angles.

These systems’ orthogonal designs, while suiting sheet metal construction, lead to air becoming stuck in corners and needing more energy to force it out.

“The most shocking thing we realised is that existing air conditioning systems basically aren’t aerodynamic and don’t even go through a computational fluid dynamic modelling process most of the time,” said Titchkosky.

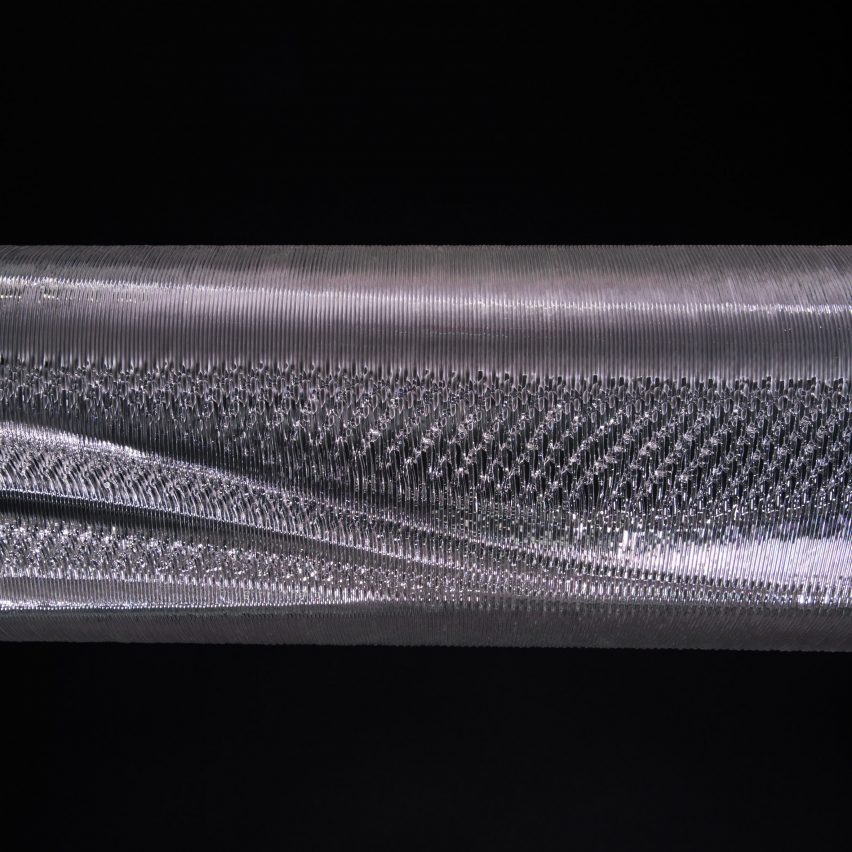

Systems Reef 2 instead has an irregular, branching form with no sharp corners, and with a tapering shape so that extra energy isn’t needed to push cool air out of the furthest reaches of the tubing.

With the friction removed from the system, it is also smaller and slimmer, using overall less material.

To increase the comfort level for people sitting under the contraption, the team drew inspiration from frogs, which breath through their skin. Instead of using ducts, they covered Systems Reef 2 in tiny pores that effectively mist cool air into the space below.

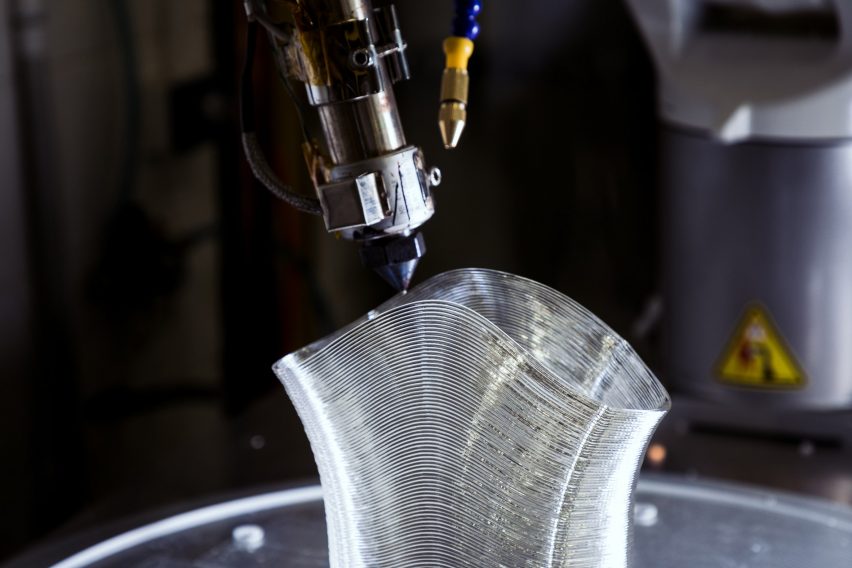

For a low-carbon material solution that is suitable for 3D printing, they chose recycled plastic, on the basis that not only is plastic waste plentiful but it can be easily recycled again and again, making Systems Reef 2 a circular design.

BVN used waste plastic that was obtained from hospitals, crushed into pellets and fed into the 3D-printing robot.

The material gives Systems Reef 2 a translucent, crystalline appearance that BVN says is “very beautiful”. There is also the possibility to print it in colours or illuminate it to personalise an office environment.

The team’s final goal for Systems Reef 2 was that it be adaptable, which they achieved with a click-and-connect system with standardised fixings and seals to facilitate easy changes.

Because it is so simple and light, BVN estimates that it cuts down on onsite labour by more than 50 per cent — a significant draw given worldwide labour shortages — while being friendlier to the health of the installers.

The team uses generative design to tailor Systems Reef 2 to specific spaces, with an algorithm generating hundreds of iterations based on a given floor plan and the final design being chosen and tweaked through manual review.

BVN installed a prototype Systems Reef 2 at its own studio in Sydney, replacing the existing tertiary ducting and diffusers. It is now exploring more demonstration projects while getting the design ready to launch as a commercial product.

It particularly sees the product as having great potential for retrofitting ageing buildings and says it could theoretically be installed in any office with an open-plan layout.

BVN and UTS were awarded Best Green Building Material/Product at the Australian Sustainability Awards 2022 for the design.

It is the second Systems Reef project BVN has undertaken, with each dedicated to some aspect of building services.

“The reason it’s called Systems Reef is because we were starting to think about all the layers that exist in the ceiling as sort of like a reef — this kind of multi-layered environment where everything plays a part,” said Titchkosky.

“We wanted to move away from the idea of a services infrastructure to a services system that was more holistically interwoven and a lot smarter.”

BVN is an Australian architecture practice with offices in Sydney, Brisbane, London and New York. Its current projects include the Sydney headquarters for technology company Atlassian, which will be one of the world’s tallest hybrid timber towers at 40 storeys in height.