Jack Hébert, the founder of the Cold Climate Housing Research Center, is credited with a phrase that’s becoming increasingly familiar to high-performance builders: “Build tight, ventilate right.” It means that as houses get tighter and better insulated, the need for well-designed mechanical ventilation gets more compelling.

At its simplest, this means using kitchen and bathroom fans to remove moist or particulate-laden air. In this exhaust-only approach, outside air finds its way into the building via gaps in the building enclosure. Supply-only ventilation works the other way: fans bring fresh air into the house, but there’s no dedicated path for stale indoor air to leave. Both of these approaches are economical but have drawbacks.

A more effective option is a balanced ventilation system in which incoming air is offset by an equal volume of outgoing air, which keeps air pressure in the building close to neutral. Builders and designers who specialize in superinsulated houses with very low air leakage rates are now likely to include either a heat- or energy-recovery ventilator in the plans. These mechanical systems are similar in that they have a core through which both incoming and outgoing air travel to transfer energy and, in the case of ERVs, moisture.

In a heat-recovery ventilator or HRV, there’s an exchange of thermal energy across the core. This is what engineers call “sensible heat.” In winter, exhaust air transfers some of its thermal energy to incoming fresh air, reducing much of the energy loss that would otherwise take place. In an energy-recovery ventilator or ERV, there is an exchange of sensible heat but also an exchange of moisture, or “latent heat.” (These systems also are called enthalpy-recovery ventilators.) ERVs are designed to keep indoor humidity levels more comfortable in both winter and summer.

A newer generation of ventilator substitutes a conventional ERV core with a heat pump. The units provide heating and cooling as well as ventilation, so they are fundamentally different from devices aimed mostly at providing fresh air with a minimum of energy losses. Two such products are the Build Equinox CERV and the Minotair Pentacare.

“Ventilation is good, but it represents a really, really large energy stream to continuously heat, cool, humidify or dehumidify that stream of air that just comes in from outside,” says Brian Ault, a senior design engineer with Positive Energy, a mechanical systems consulting firm. “HRVs and ERVs help reduce the amount of energy that takes plus, they can filter it, so you can catch most of the big stuff before it comes into the house.”

There are more than a dozen manufacturers that offer ERVs or HRVs (or both) to buyers in the U.S., including familiar ventilation brands such as Broan, Fantech, Panasonic, and RenewAire, along with companies that may be a little less familiar to U.S. homeowners, such as Zehnder, a Swiss company that makes the high-end ComfoAir systems. (The Home Ventilating Institute, an industry trade group, maintains a list of manufacturers on its website, which is available here.)

Air distribution systems for HRVs and ERVs vary widely. At one end of the scale are systems that include dedicated supply and exhaust ducts to key rooms in the house. That ensures a constant and well-distributed source of clean outdoor air but at a relatively high cost. Other systems are less complex and may even use existing HVAC ducting to distribute outdoor air. Through-the-wall appliances provide fresh air for a single room.

Costs for installing a system in a typical 2000-sq.-ft. house range from about $3000 or less to nearly $10,000 for a high-end system with more complex ducting. (The units themselves are much less expensive, ranging from less than $1000 to nearly $4000 for a top-end model.)

The Basics of System Operation

The heart of an ERV or HRV is a metal box with four ports. Inside, the core of a heat exchanger looks something like corrugated cardboard and allows incoming and outgoing air to cross paths without actually mixing. HRV cores, Ault said in a telephone call, are fairly simple, consisting of aluminum or another light metal with good heat-transfer properties.

“They’re not awesomely efficient,” he said, “but they have effectiveness ratings somewhere between 50%-60% up to 95% depending on the size, the brand, and how much air flow goes through them.”

ERVs get more complicated. Instead of a basic aluminum heat exchanger, an ERV typically has a core made out of a polymer embedded with a desiccant, a material that absorbs moisture. The core material permits the passage of some moisture, although it’s still air-impregnable, so the airstreams don’t mix. According to Ault, this type of cross-flow core is common in a residential unit, where airflow rates are lower than 250-300 cubic feet per minute (CFM). Above that, in commercial buildings, office buildings, and schools, it becomes more practical to use a rotating wheel with a desiccant.

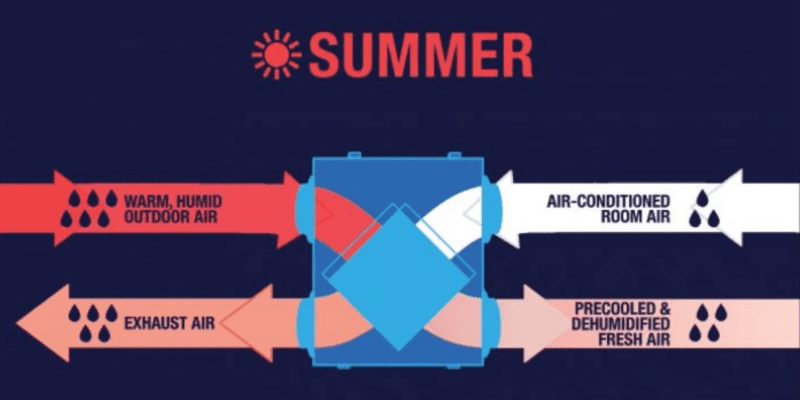

In the summer, outgoing air that has been cooled pulls some of the heat and humidity from the incoming airstream. Illustrations courtesy RenewAire.

In winter, an ERV helps indoor air retain moisture. The heat exchanger also warms incoming fresh air.

A three-bedroom, 2000-sq.-ft. house would typically need a system rated at 90-100 CFM To meet ASHRAE ventilation requirements, Ault said. Sensible heat recovery in an HRV averages about 70%. In an ERV, a certain amount of sensible heat recovery is taking place. The latent recovery is usually between 40% and 60%, so about half the moisture difference in the two airstreams will be transferred through the core.

“It is an appreciable amount of latent energy when you have a legitimate difference between your indoor and outdoor moisture levels,” Ault said. “Up north, it’s dry as a bone outside for four or five months out of the year in the winter. In the summer, sometimes it’s about the same as inside the house. Farther south, that’s flipped.”

In humid parts of the country—the southeast U.S.—running an ERV during the summer does not lower indoor humidity. An ERV will actually increase indoor relative humidity because the outdoor air doesn’t shed all of its moisture on its way indoors. But the problem would be worse if an HRV were installed because there is zero moisture transfer in an HRV. Even though moisture levels will go up when running the ERV, stale indoor air is being exhausted and fresh outdoor air is being introduced. A dehumidifier or an air conditioner can deal with excess humidity.

According to Ault, ERV cores eventually get plugged with oil, skin cells, hair, and dust and should be replaced every four to 12 years. A less complicated HRV core should go for a couple of decades without any major maintenance. When it gets dusty, a homeowner can just clean it off with compressed air.

The key, however, may be in changing filters regularly, not in any inherent flaws in core design that limit their life span. In this BS* + Beer Show episode, which aired last fall, Enrico Bonilauri of EMU, a Passive House consulting firm, noted that the only moving parts in an HRV or ERV are the fans, so there’s not much to wear out, and cores can last for decades providing that filters are changed on schedule.

Bonilauri also noted that heat recovery rates for many models might be overstated because the heat generated by fans inside the unit may incorrectly be attributed to heat recovery. In units that are not certified by the Passive House Institute, he said, the stated heat recovery rates should be reduced by 12%.

Choosing between an HRV and an ERV

A great deal of ink has been spilled by researchers and journalists on the question of whether an HRV or ERV is the best choice.

According to Jacki Donner, the Ventilating Institute’s CEO, the decision has been boiled down to where you live. Historically, HRVs were more common in houses in colder climates because the chief concern was the amount of thermal energy that could be saved. Humidity was seen as a secondary problem. The most efficient units on the market capture more than 80% of the heat in the outgoing airstream and transfer it to incoming air—in really cold environments, that’s a big plus. ERVs were typically specified in places with hot, humid summers because they transfer some of the moisture in indoor air to the outgoing air, thereby making indoor relative humidity more tolerable than it would be with an HRV.

But there is nothing simple about this debate. For example, there’s a good case to be made for ERVs in cold, northern climates. Cold air holds less moisture than warm air, so during the winter outdoor air is very dry. When it’s brought into the house without any attempt to salvage the moisture from the outgoing airstream, indoor air can get uncomfortably dry.

This Zehnder HRV includes a number of supply and exhaust ducts. Ducted distribution systems run the gamut from complex, like this one, to simple designs with only a few supply and exhaust ports. Photo courtesy Alex Wilson.

How this plays out depends on the size of the house, the number and behavior of the occupants, and how tight the house is. In small houses with very little air leakage and lots of people, high indoor humidity can be a problem in the winter. An HRV can make it more comfortable. But a large, leaky house in a cold climate may already be very dry during the winter, so an ERV will help prevent it from becoming too dry. In other words, there is no simple formula that fits every house and every climate. (For a detailed discussion of the variables that go into making this decision, read this article by Martin Holladay. Although it is more than a decade old, the basics have not changed.)

Donner says that while HRVs have historically dominated the market, especially in Canada, that’s changing. “Today and moving forward, ERVs are used more and more throughout the USA,” Donner said in an email. “A similar situation is occurring in Canada.”

ERVs have been more expensive than HRVs in the past, but that gap is narrowing, and designers are recognizing the importance of capturing humidity in the winter, Donner said, giving ERVs a lift even in areas where HRVs once ruled.

Nick Agopian, vice president for sales and marketing at RenewAire, raised two other points. In a telephone call, he said that HRVs are more difficult to install. They have to be oriented in only one way so condensate drains work properly (ERVs can be installed at any orientation). In cold weather, HRVs are more likely to freeze up, he added, requiring a defrost cycle.

RenewAire, which began life as a solar energy company in the 1970s before branching into ventilation, decided in the early 1980s to focus on total energy rather than sensible energy alone. The company doesn’t make an HRV. “Where ERVs used to be 25% [of the market], and HRVs were usually 75%, it’s now shifted,” Agopian said, “because at the end of the day, they cost about the same price and they perform on the whole aspect rather than on the sensible aspect of energy transfer.”

“An HRV is used to save energy,” he said, “but an ERV is also used to downsize the capital costs of [air conditioning or dehumidification] equipment. If we’re going to lower the temperature, we can downsize the equipment. But if the humidity stays the same and you still have to dehumidify, you can’t downsize. All you’re doing is saving a portion of that energy, but your capital equipment still needs to be the same size, and it has to work hard to dehumidify that air.”

Heat transfer in an ERV typically isn’t quite as good as with an HRV, he said. And as the latent energy performance of an ERV is increased by making the desiccant-laden membrane thicker, the thermal performance goes down. But nationally, the tide seems to be turning toward ERVs.

“Deciding between an ERV and an HRV should land on ERV most of the time,” says Allison Bailes III, a Georgia-based consultant. “In a warm, humid climate, an ERV brings in less outdoor humidity than an HRV. (An ERV isn’t a dehumidifier. It does still add to the latent load in the house.) In a hot, dry climate, an HRV will make your already dry air even drier. In a cold climate, bringing in outdoor air without moisture exchange can result in extremely low humidity in winter. Only in mild climates like the West Coast of North America do HRVs make sense – sometimes.”

In an email, Bailes added that occupancy is another factor to consider. “The higher the density of people in a space, the more you might need to dry out the air with an HRV,” he said. “A small, airtight apartment or condo with two or three people in it, for example, may be too humid indoors with an ERV.”

Bailes continued: “Another reason people choose HRVs is that they’re more efficient at transferring heat than are ERVs. What good is it to have high-efficiency ventilation, though, if you end up growing mold? The primary way to choose between an ERV and an HRV is to understand the moisture control needs of the space being ventilated.”

Ductless HRVs and ERVs

Several manufacturers offer through-the-wall HRVs and ERVs designed for smaller spaces. They include the Zehnder ComfoAir 70 ERV, the Panasonic WhisperComfort ERV, the Lunos e2 and eGO, and the TwinFresh Comfo RB-1-50. These ductless ventilators move relatively small volumes of air so they are best suited for small spaces. Zehnder’s model has a maximum capacity of 35 CFM, for example, while the Lunos e2 is rated only up to 22 CFM.

A pair of Lunos through-wall ERVs, working in tandem, are designed for small spaces. They alternate between exhaust and supply modes with a reversing fan. Image courtesy 475 High Performance Building Products

At least two of them have a ceramic core that serves as the heat and moisture exchange and a fan that reverses direction. Exhaust air warms up the core, and when the fan runs in the opposite direction, incoming air recaptures that heat (and in some cases, moisture). The Lunos e2s are installed in pairs and operate on opposing cycles of exhaust and supply, which the manufacturer says results in balanced ventilation.

These devices are much less expensive than the whole-house models that require some ducting. But because they have lower capacities for air flow, it might be necessary to install a number of them in order to reach recommended ventilation rates for the whole house. That can get expensive.

COVID-19 and other health concerns

The growing impact of wildfires in the West and the unrelenting spread of COVID-19 raises other questions about indoor air quality and public health. Filters for incoming air can help reduce the levels of dangerous particulates—especially those measuring 2.5 microns in diameter called PM2.5—along with the other junk that’s often found in outdoor air. MERV-13 filters are typical, but more effective HEPA filters can be substituted when outdoor air conditions are especially challenging. Bringing fresh air into the house dilutes pollutants that remain, but filters should be checked regularly.

When it comes to COVID, transmission rates are lower when indoor relative humidity is in the 40% and 60% range, according to this article posted last fall by researchers at the Harvard T.H. Chan School of Public Health. That suggests ERVs may be more beneficial during the winter in cold-climate areas because they help keep humidity higher than it would be otherwise. Although an HRV has higher thermal efficiency, in some situations, an HRV can make indoor air too dry during the winter.

ASHRAE offers detailed guidance on the operation of ERVs during the pandemic in this document published last year.

Deciphering Flow Rate Requirements

Determining how much fresh air a ventilation system should provide can give even experts a headache. “It’s hard,” admitted Cramer Silkworth of Baukraft Engineering in the aforementioned BS*+ Beer episode. The IRC requires buildings with air leakage rates of less than 5 ACH50 to have whole-house mechanical ventilation, but standards on exactly how much are evolving.

The benchmark is ASHRAE Standard 62.2. In pre-2013 versions, it required supply air of 0.01 CFM of ventilation air per sq. ft. plus 7.5 CFM per occupant; on the exhaust side, it called for 25 CFM of continuous ventilation in kitchens (100 CFM supplied intermittently), and 20 CFM in the bathroom for fans run continuously (50 CFM for intermittent operation). In versions of 62.2 published after 2013, supply air requirements went up sharply, while exhaust air minimums followed a new schedule in the kitchen, depending on whether a range hood was used. Passive House requirements are more demanding.

Building scientists were divided on whether the changes were a good idea. Some experts argued that even the old requirements were too high because they tended to result in high indoor moisture in humid climates.

The bottom line can be no absolutes, even for engineers like Silkworth who work with system specifications all the time. His approach is to use the code-required ventilation rates in whatever jurisdiction he’s working in as a minimum. To that, he likes to add another 25% to 50% in capacity at least in boost mode.

“It depends a lot on what’s going on in that building and what the occupants are doing,” he said in a telephone call. “It’s hard to nail down any one specific formula for maintaining good air quality. More fresh air is better, especially now with all of the COVID concerns, but there’s the energy expense and especially humidity control you have to add to those systems. So, until we have free dehumidification and heating and cooling and filtration on all these systems, it’s a battle between those two factors—you need enough but not too much, and it’s really hard to say what those levels are.”

The system should be commissioned after it has been installed to make sure it’s performing as designed, he said, and filters should be changed on a regular basis.

Another question is whether the systems should run continuously or intermittently. Older systems use one-speed fans and simple controls. With intermittent operation, the system effectively runs at variable speeds without the cost and complexity of variable-speed motors and controls, Silkworth said. Variable-speed motors, however, are becoming more common. They can be sized for peak demand (boost mode) but run at 75% of capacity most of the time. Those systems are quieter and more efficient, but they still have the peak capacity they might need a few hours of the day.

Asked whether ventilation systems that run continuously are best for indoor air quality, Silkworth said: “Yes, but if you have a cycling system that goes on and off every 15 minutes, I don’t think that 15 minutes of off time is going to kill your air quality to any noticeable extent—unless we’re talking about a densely occupied conference room or something like that. If it were hours between cycles, that would be a problem.”

A compromise between lower-cost systems with one-speed motors and more expensive systems with variable-speed motors are two-speed fans that are becoming more common, he said, adding, “If that could be a standard option, that would be great.”

Distribution Takes Many Forms

Fresh air can be distributed around the house in one of many ways. As described in this paper published by the Building Science Corp., the simplest is a “single-point” system with one supply duct and one exhaust duct. Pulling indoor air from the master bedroom pulls fresh air in from other sources. When there is no central air handler available, this type of system is inexpensive, but it doesn’t ensure ventilation air will be distributed evenly around the house. Spot ventilation would be required in bathrooms and kitchens.

This simple system has one supply duct and one exhaust duct, along with spot ventilation in the kitchen and bathroom. Drawing courtesy Building Science Corp

This simple system has one supply duct and one exhaust duct, along with spot ventilation in the kitchen and bathroom. Drawing courtesy Building Science Corp.

In a multi-point system, fresh air is distributed to bedrooms and main living areas while stale air is drawn from common areas, such as a hallway, the kitchen and bathrooms (exhausting a cooking area with an HRV/ERV is not recommended). Building Science Corp. says these fully ducted systems represent best practice and are the most efficient but also the most expensive. They also are effective where there is no central air handler available.

An air handler also can become part of the distribution system. Fresh air is routed through the HRV/ERV and into the supply side of the air handler, as shown in the diagram below. Returns to the air handler go through a filter, and other ducts pull stale air from indoors and direct it to the HRV/ERV. These systems also mean whole-house distribution and come with moderate cost. A variation is to draw the exhaust air for the HRV/ERV directly from the air handler’s return trunk while supplying all fresh air through the air handler’s ducts.

This distribution system uses the air handler in the HVAC system to distribute fresh air from an HRV or ERV. It also includes kitchen and bathroom fans for spot ventilation. Drawing courtesy Building Science Corporation.

Zehnder’s devices, which have become well known to those building and designing high-performance houses, are examples of a multi-point system. They are among the most expensive on the market, with installed prices in a single-family home approaching $10,000. But they are highly rated and have very high thermal transfer rates.

Less sophisticated systems will be much less expensive, but to advocates like Agopian, it’s all about the importance of fresh air and good health. He may be in sales, but the RenewAire executive was part of an ASHRAE working group studying ventilation requirements for multifamily dwellings and is well versed in the technical side of the business.

One of his biggest frustrations is the relative lack of attention to indoor air quality in U.S. buildings and the reluctance of homeowners and builders to invest a few thousand dollars in a mechanical system that can dramatically improve health. He calls ventilation “preventive medicine” that can be more effective than medication people have to take after they’ve developed health problems because of exposure to air pollutants in their own homes.

Buyers choose a model of HRV/ERV because of cost differences, he said. Cost-conscious buyers object to requirements for higher ventilation rates that mean only marginal increases in energy costs.

“Really?” he said, “so you’re going to put a $10,000 granite countertop or a $20,000 Wolf range in your house because you want it to look good, but you’re worried about putting in even a $4000 ERV when I can show you that it will improve your life?”

By Scott Gibson

Scott Gibson is a contributing writer at Green Building Advisor and Fine Homebuilding magazine. This article originally appeared in Green Building Advisor.