Using biotech for sustainable chemical manufacturing

Spotted: The global chemical industry emits more than two gigatons of carbon dioxide each year, according to Deloitte. And many of the catalysts used to accelerate reactions today contain heavy metals which can contaminate the environment if not disposed of properly. This has sparked the interest of new generation of innovators who are looking to make the chemicals industry more sustainable.

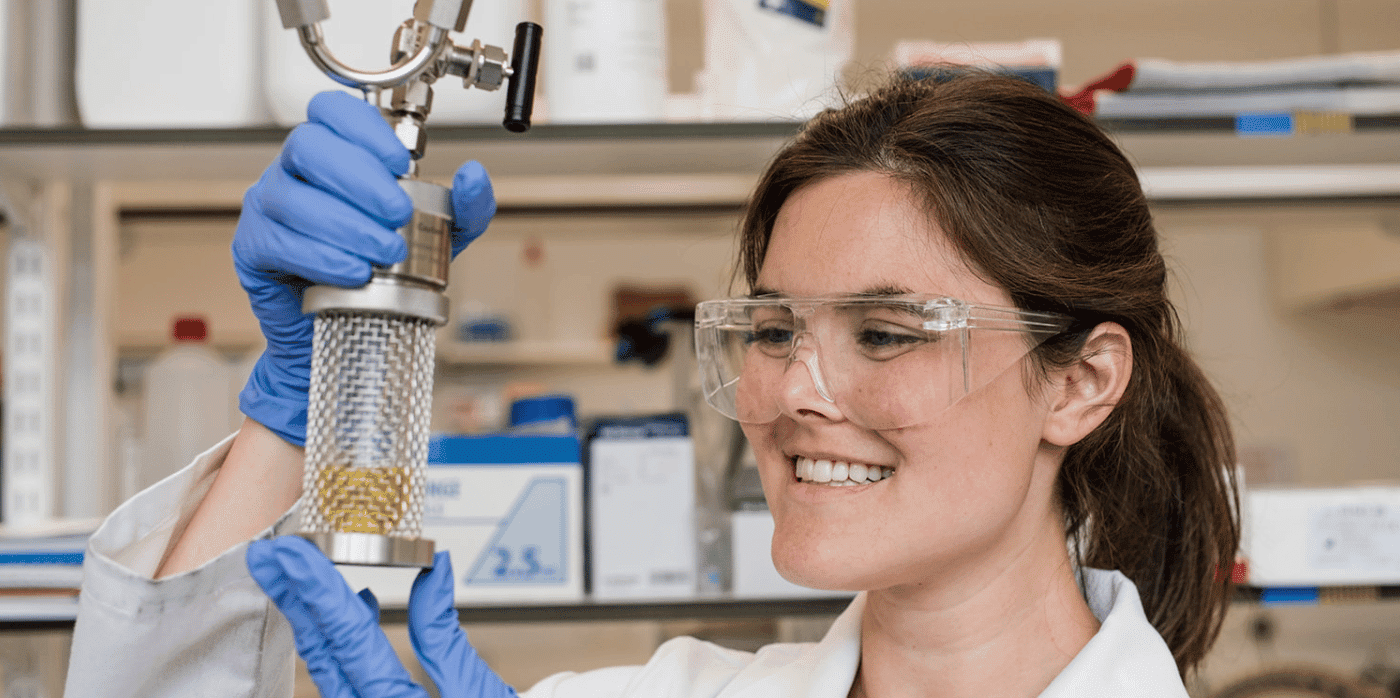

One way to do this is to replace metallic catalysts with something healthier that can underpin less energy-intensive processes. To this end, Oxford biotechnology company HydRegen has created a bio-based manufacturing material that replaces heavy metal catalysts. Using a bio-based catalyst allows the production process to work on lower temperatures and lower pressure. That decrease then reduces the amount of energy needed to run the process, which contributes to a significantly lower carbon footprint.

HydRegen’s compounds are designed to slot into existing infrastructure as direct replacements for the toxins used by the pharmaceutical and chemical manufacturing industries. One of HydRegen’s investors estimates that if Paracetamol production switched over to biocatalysts, the industry would save hundreds of thousands of tonnes of CO2 emissions every year.

The company works with organisations at all stages of production and can supply a range of biocatalysts from very simple to complex new materials that work with a business’s proprietary enzymes. HydRegen recently raised £2.6 million (around €3 million) in investment to use for licensing its technology and expanding the team in order to support commercial deployment of the innovation.

Industrial manufacturing contributes so many toxins to the environment that Springwise has spotted a range of innovations – such as artificial intelligence (AI) used in net-zero metal casting and a copper replacement that stores carbon – that are helping to clean up the industry.

Written By: Keely Khoury