Lars Beller Fjetland designs “100 per cent recyclable” aluminium bench

Norwegian designer Lars Beller Fjetland explains how his fully recyclable Bello! bench created for Hydro aims to showcase the possibilities of extruded aluminium in this exclusive video produced by Dezeen.

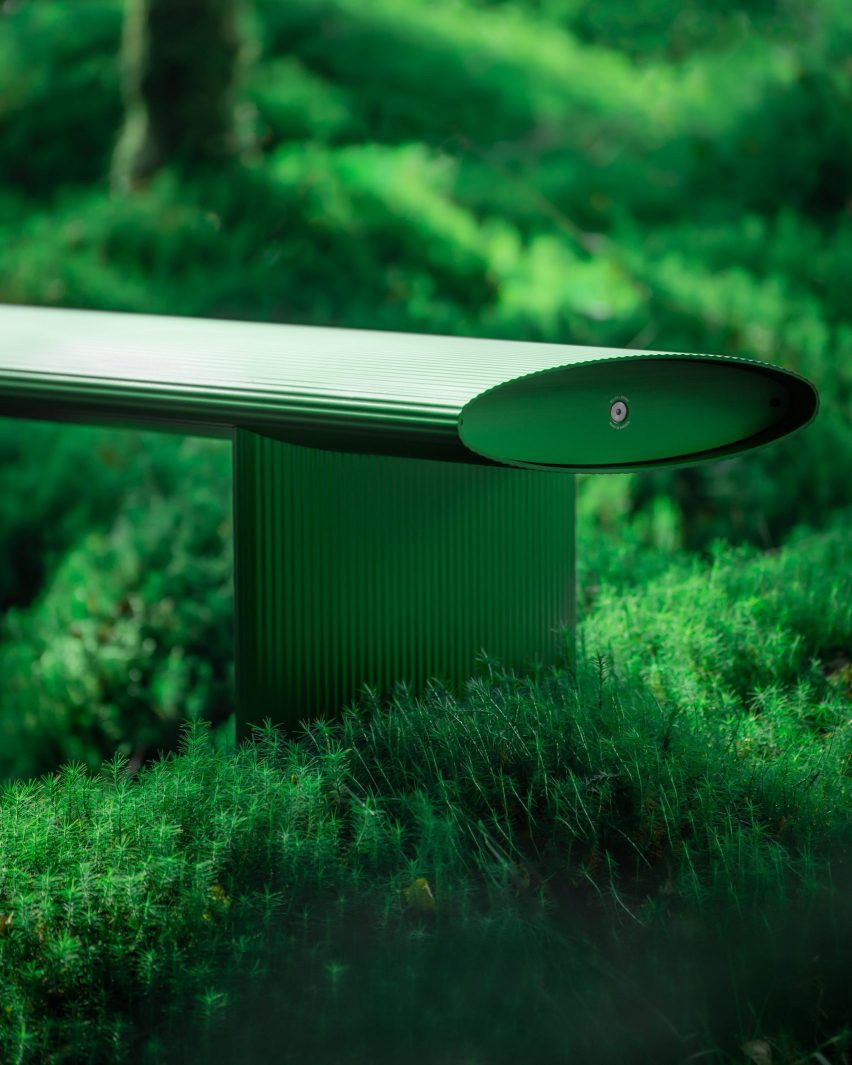

Designed in collaboration with Shapes by Hydro – a knowledge hub created by aluminium producer Hydro – the bench is made from nearly 90 per cent recycled and 100 per cent recyclable aluminium, according to the designer.

“I wanted to make something that was extremely robust, and for me, aluminium was the answer,” Beller Fjetland told Dezeen. “It has all these amazing properties that make it a super durable material, especially when you introduce it in an anodised finish.”

Beller Fjetland and Hydro recently presented the latest colourway of the bench in forest green during the Material Matters Fair during London Design Festival, where Beller Fjetland spoke to Dezeen about the collaboration.

He cited forest landscapes as a source of inspiration when creating the vibrant green seat.

“I was just walking in the forest and contemplating aluminium as a material, and I was thinking about having a light impact or a low footprint in nature,” Beller Fjetland said.

“Green just felt really fitting. It can also be a cliche, in a way, to think about green, but I think for us it really works.”

The bench is characterised by its ridged surface, which Beller Fjetland explained was informed by the shape of penne rigate pasta.

“One of the things we discussed was how can we make the concept of extrusions accessible for as many people as possible,” Beller Fjetland explained in the video.

“That’s where I started to think about the analogy with the pasta, because the manufacturing technique is surprisingly similar.”

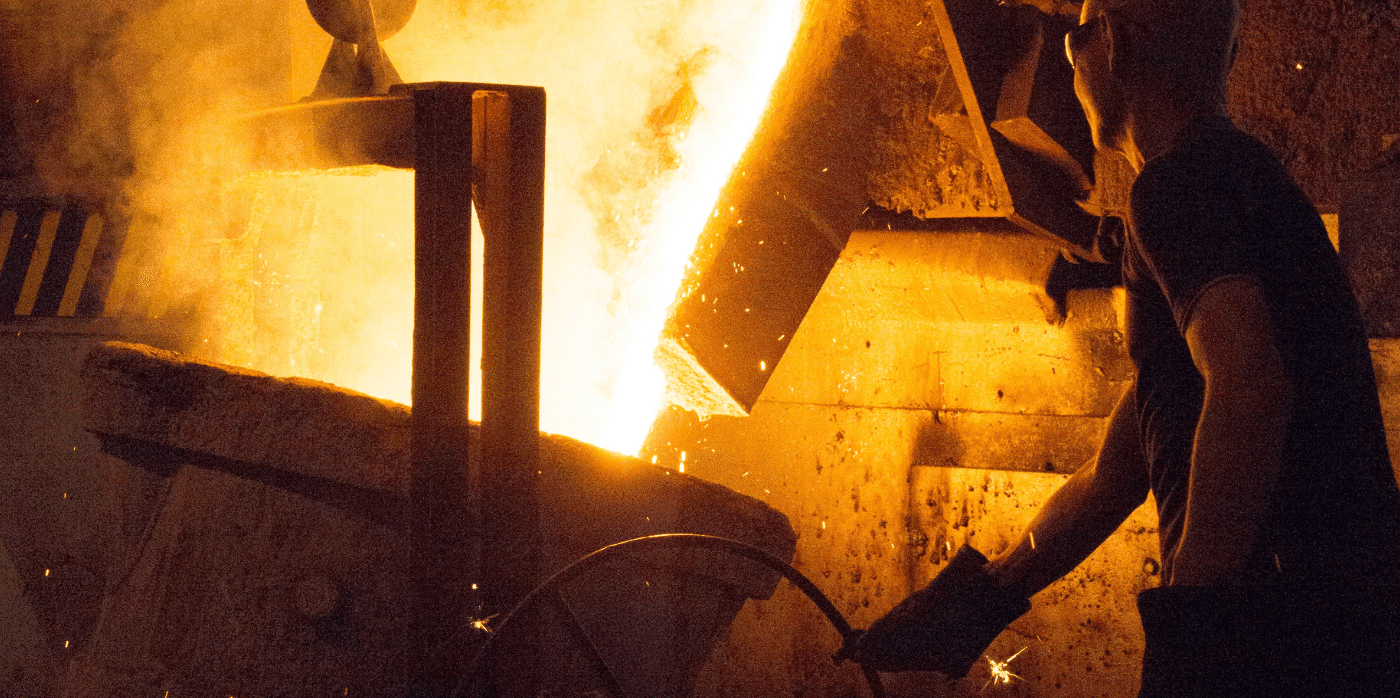

The bench is manufactured using a similar extrusion process to how dried pasta shapes are formed. For the Bello! bench, molten metal is poured through a moulded opening to create a ridged surface.

“You’re pushing the material through a die, which creates a form and, visually, it looks like a penne rigate or a rigatoni pasta,” Beller Fjetland explained.

The bench, which was designed for both inside and outdoor use, features a hard-wearing finish making it suitable for high-traffic settings such as public transportation hubs.

“What is interesting with aluminium is that it is a material that has an inherent value in itself, which kind of makes circularity way easier,” Beller Fjetland said. “There’s an incentive there to actually recycle the material, because it has a monetary value.”

“The beautiful thing is that the energy needed to recycle aluminium to make new material is very low. It makes me believe that recycled material doesn’t have to be a compromise,” he continued.

Partnership content

This video was produced by Dezeen for Shapes by Hydro as part of a partnership. Find out more about Dezeen partnership content here.