Aerogels freeze the costs of cold chain logistics

Spotted: An efficient cold chain is vital for ensuring maximum agricultural efficiency and reducing post-harvest losses, as well as for keeping delicate pharmaceutical products safe. However, refrigeration uses a lot of energy. In fact, according to the UN Industrial Development Organization (UNIDO), the refrigeration sector is currently responsible for around 17 per cent of global electricity consumption. To reduce this, KrossLinker has developed what it claims is the world’s most insulating nanomaterial.

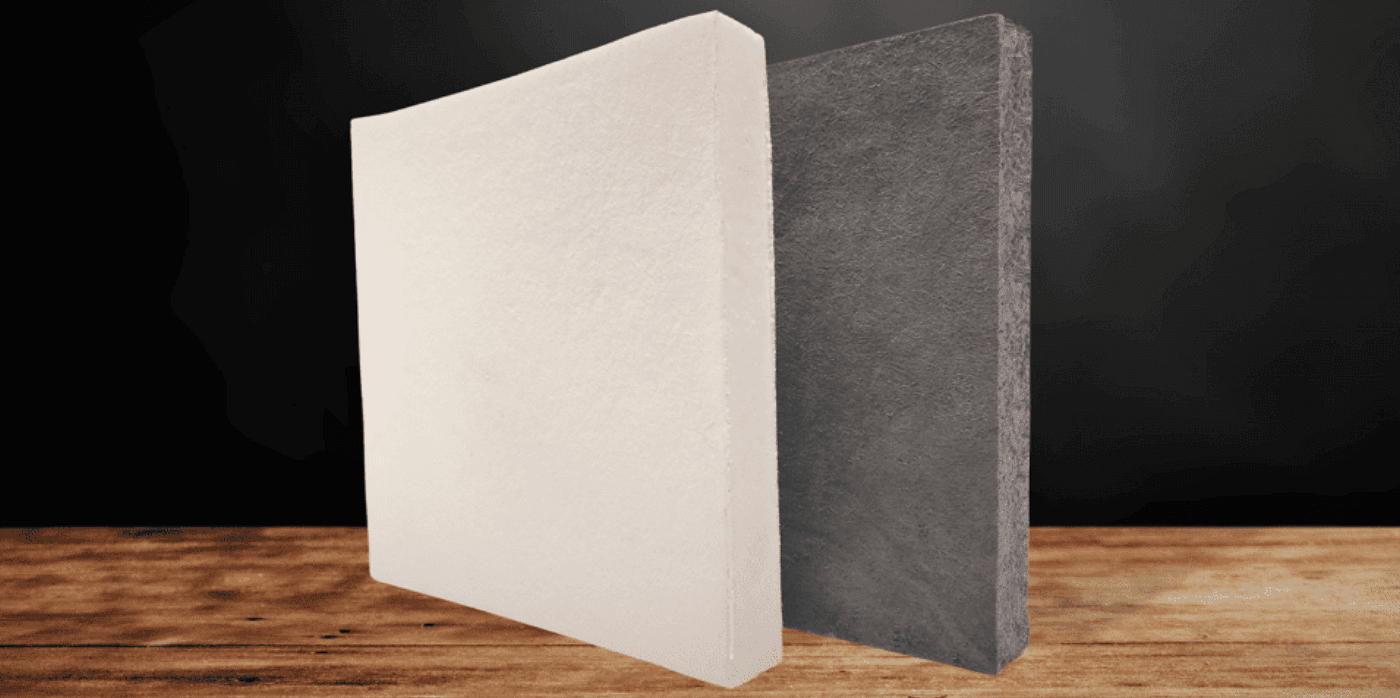

Earlier this year, the startup released its first commercial aerogel product, called Cryar Aerogel Board. This is a water-based, Silicon Aerogel composite board designed to reduce the energy needed to keep pharmaceutical and food products cold during shipping, with its nano-porous structure providing excellent thermal insulation.

The company’s aerogel is lightweight, non-toxic, and reusable. It is made using a novel drying technique that reduces the energy consumption of the finished product while speeding up production. KrossLinker claims that its product is made at half the cost of traditional aerogels.

KrossLinker has collaborated with a number of packaging logistic companies to accelerate the adoption of Cryar aerogel shipping containers. Beyond the cold chain, KrossLinker’s technology also has applications in the manufacturing of electric vehicles (EVs) and building construction.

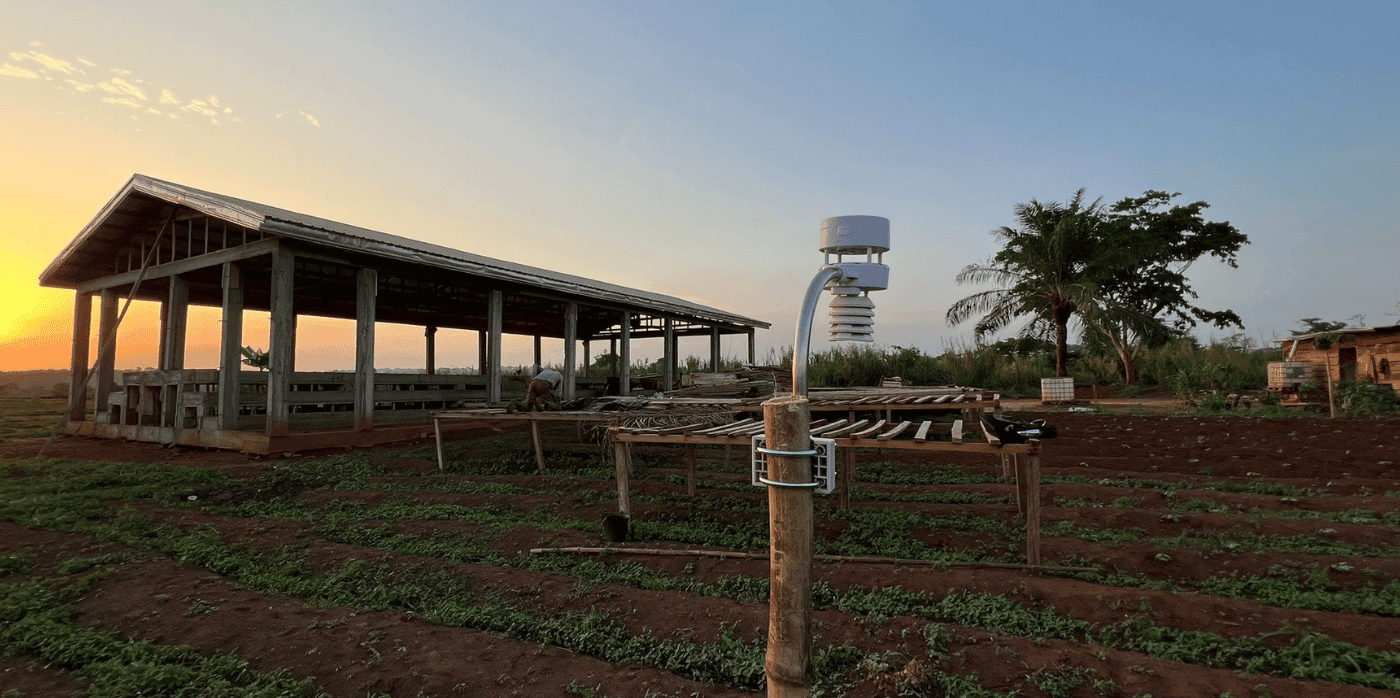

The energy consumption of the cold chain industry is the subject of a number of recent innovations spotted by Springwise. These include solar-powered cooling for the livestock industry and the use of compostable materials for cold chain packaging.

Written By: Lisa Magloff