Cleaning products that embrace the refill revolution

Spotted: As plastic waste continues to proliferate around the globe, an increasing number of campaigners and organisations are moving towards reuse as a solution that will ultimately be more effective than recycling in terms of tackling our waste problem.

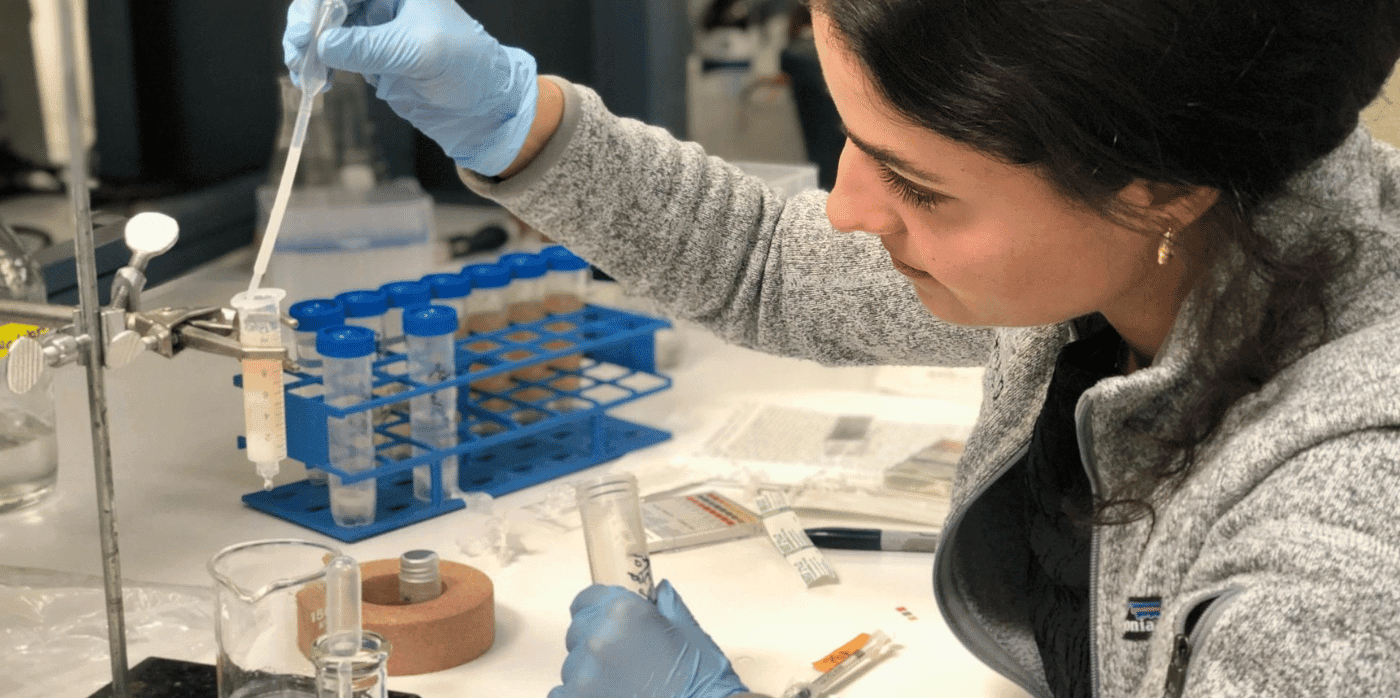

One way single-use plastics can be reduced, is to eliminate the need for them through the implementation of refillable products. In the UAE, sustainable cleaning company Kyma has created a tablet-based refill solution that uses a single squirt bottle for all household cleaning needs.

Customers buy small boxes of refill tablets and drop one in a bottle of warm tap water when a cleaning solution is needed. Kyma’s cleaning tablets are biodegradable and non-toxic and come in four categories: as well as a bathroom and multi-surface cleaner, Kyma also provides a glass-specific cleaner and disinfectant.

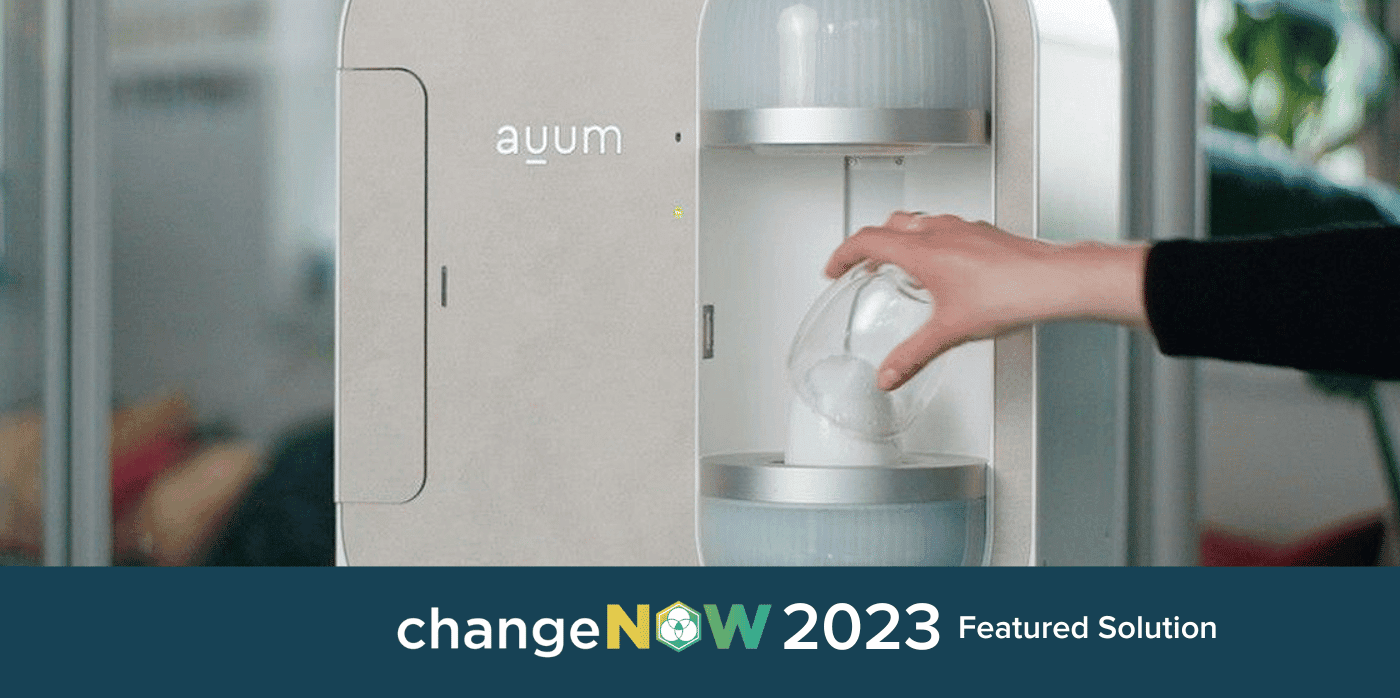

Designed with a healthy home in mind, the products are not tested on animals and are safe to use around children and pets. The refills come in simple paper boxes, making them easy to stack. Using the refill solution frees up general home storage space as cabinet shelves in bathrooms and kitchens no longer need to hold so many bottles of cleaning solutions.

The three co-founders use the phrase ‘refillution’ to describe the scale of the solution needed to fix the world’s single-use plastic problem. The company currently ships across the UAE and beyond, and with an initial line of household cleaning products already available online, Kyma is also working to develop additional ranges of lifestyle items.

Springwise’s library includes a number of innovations using the refill and reuse approach to reducing waste, from a zero-waste household goods subscription service to drinks vending machines that work with customers’ own bottles.

Written By: Keely Khoury