A new era of energy: district heating and cooling that uses CO2

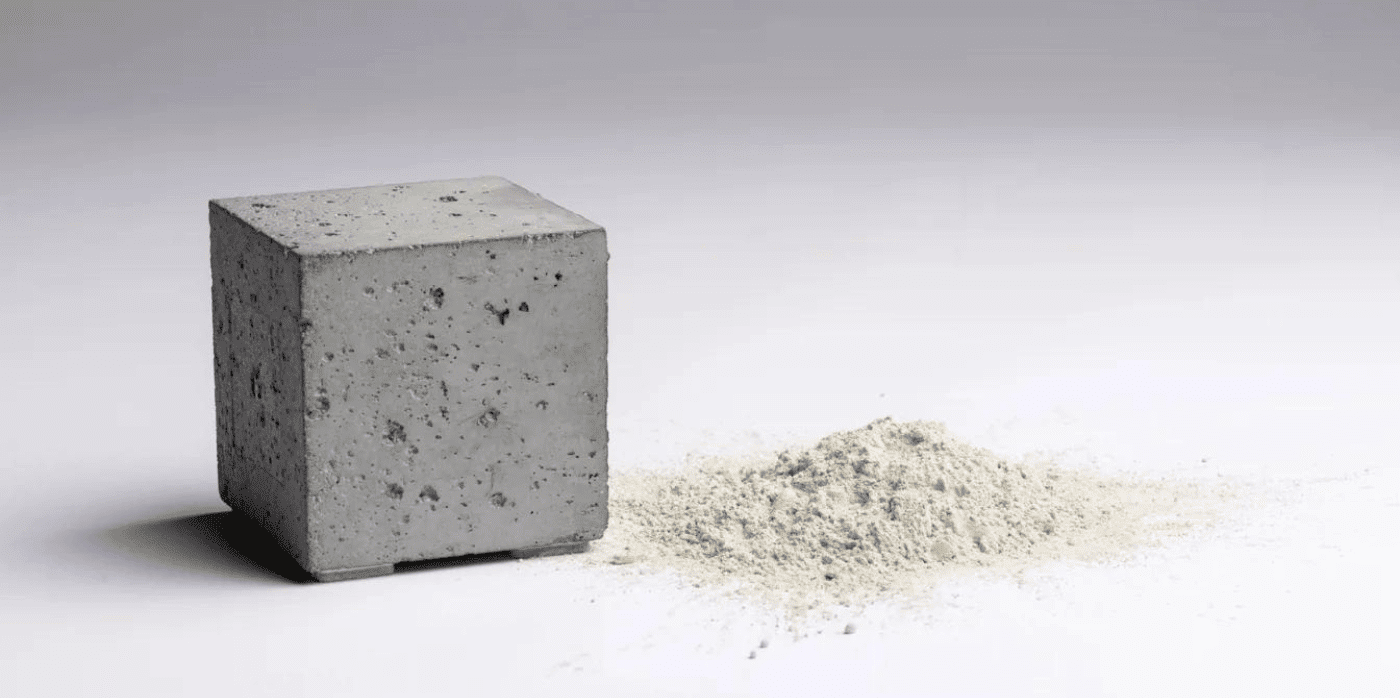

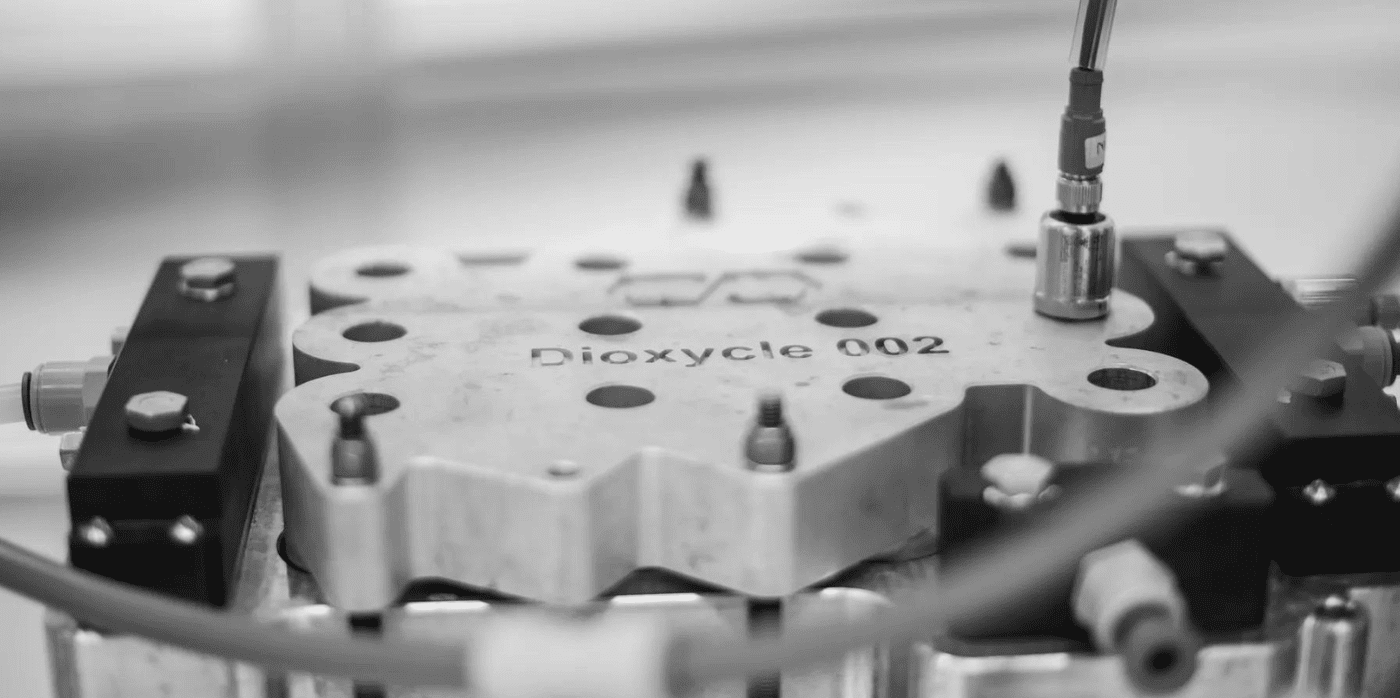

Spotted: Almost 25 per cent of the energy produced worldwide is used to heat and cool homes and commercial buildings. And the process of generating this energy is a major source of greenhouse gas emissions. District heating and cooling systems are one potential solution. These generate heat centrally and distribute it across a network of buildings in the same neighbourhood, which is more efficient than heating or cooling buildings individually. Usually, such systems use water to transfer heat, but now, Swiss cleantech startup ExerGo is using CO2 as an energy transfer fluid for its closed-loop system.

The CO2 is the basis of a thermal network powered by renewable resources and waste heat. By using liquid and vapour CO2 as a working fluid, the system increases energy transport efficiency over conventional water-based systems. This greater efficiency, in turn, allows for the use of small and more flexible piping, which can save up to 60 per cent in installation costs and time, while reducing noise and air pollution. ExerGo claims that its compact network can save up to 80 per cent in primary energy consumption over comparable fossil fuel-based systems.

In October last year, ExerGo won the European Heat Pump Association‘s Heat Pump City of the Year Award for the successful implementation of its technology in Sion, Switzerland.

Springwise has spotted other technologies that are helping to decarbonise the energy-intensive cooling and heating systems used around the world, including a heat pump that is powered by sound and affordable geothermal heating and cooling systems.

Written By: Lisa Magloff