The world’s first commercial CO2-to-methanol plant

Spotted: Methanol (CH3OH) is a chemical building block used in hundreds of everyday products, including plastics, paints, and car parts, as well as a clean-burning fuel. However, methanol production itself is not clean – it is produced in an energy-intensive process that usually begins with natural gas: a fossil fuel. Now, Carbon Recycling International (CRI) is working on a way to change this with a production process that uses captured waste carbon dioxide and hydrogen gases.

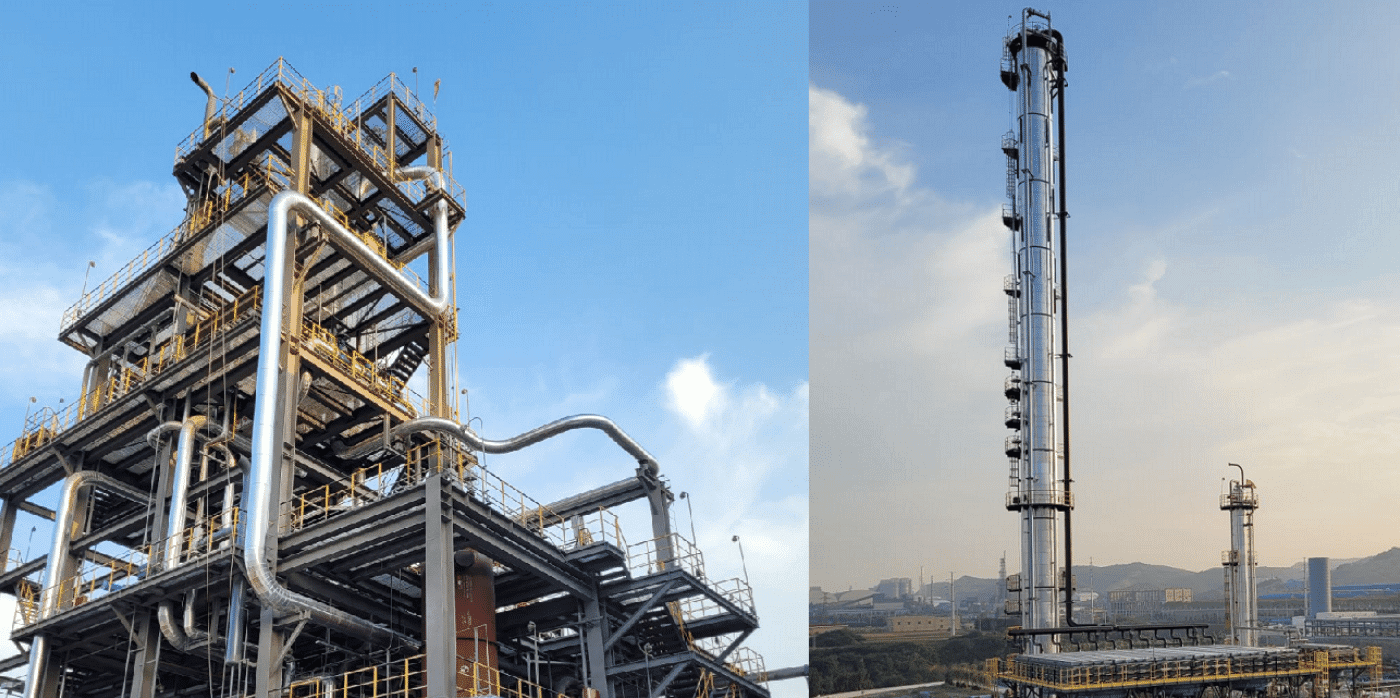

CRI has recently completed the world’s first commercial-scale CO2-to-methanol plant, located in Anyang, Henan Province, China. The cutting-edge facility uses Emissions-to-Liquids (ETL) technology developed by CRI and first demonstrated at its pilot plant in Iceland. This process uses carbon dioxide that is recovered from existing lime production emissions, and hydrogen recovered from coke-oven gas. The waste gases are captured at their point of emission and transferred to the gas conditioning system, where impurities are then removed to produce carbon dioxide. At the same time, hydrogen is generated by water electrolysis using a renewable electricity source.

Björk Kristjánsdóttir, CEO of CRI, explains, “We are proud to have successfully realised this important project and to bring our environmentally friendly, ETL technology into the global market. This technology can support large-scale reduction of carbon emissions and help facilitate the energy transition.”

To meet the goal of zero carbon, it is going to be necessary to find low-carbon methods for producing basic materials. Springwise has also spotted a method for making protein out of methane and turning waste CO2 into carbon fibre and wastewater treatment chemicals.

Written By Lisa Magloff