Could this system cut the carbon cost of air-con?

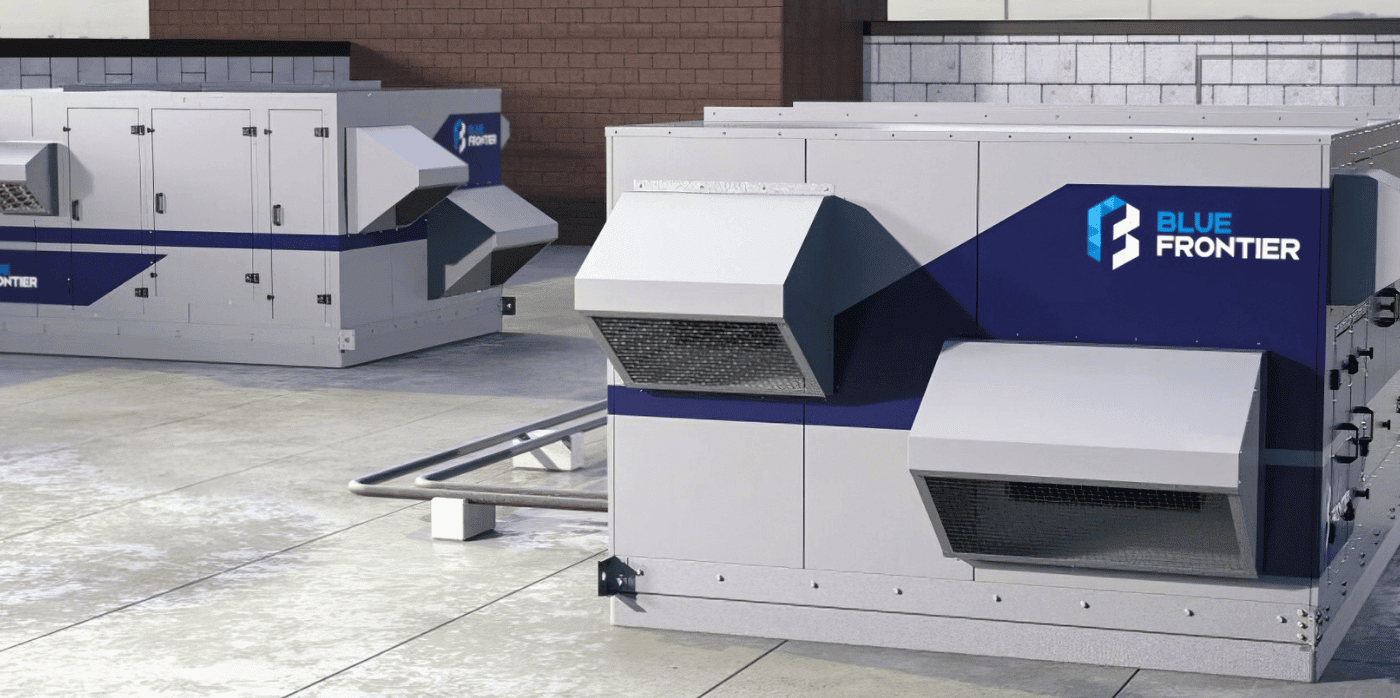

Spotted: Climate change has led to more frequent and severe heatwaves, and the increasing need to stay cool indoors is, in turn, speeding up global heating. Researchers have calculated that air conditioning is responsible for around 3.9 per cent of annual global greenhouse gas emissions and startup Blue Frontier Inc. has developed an ultra-efficient, sustainable air conditioning (AC) technology to tackle this climate footprint.

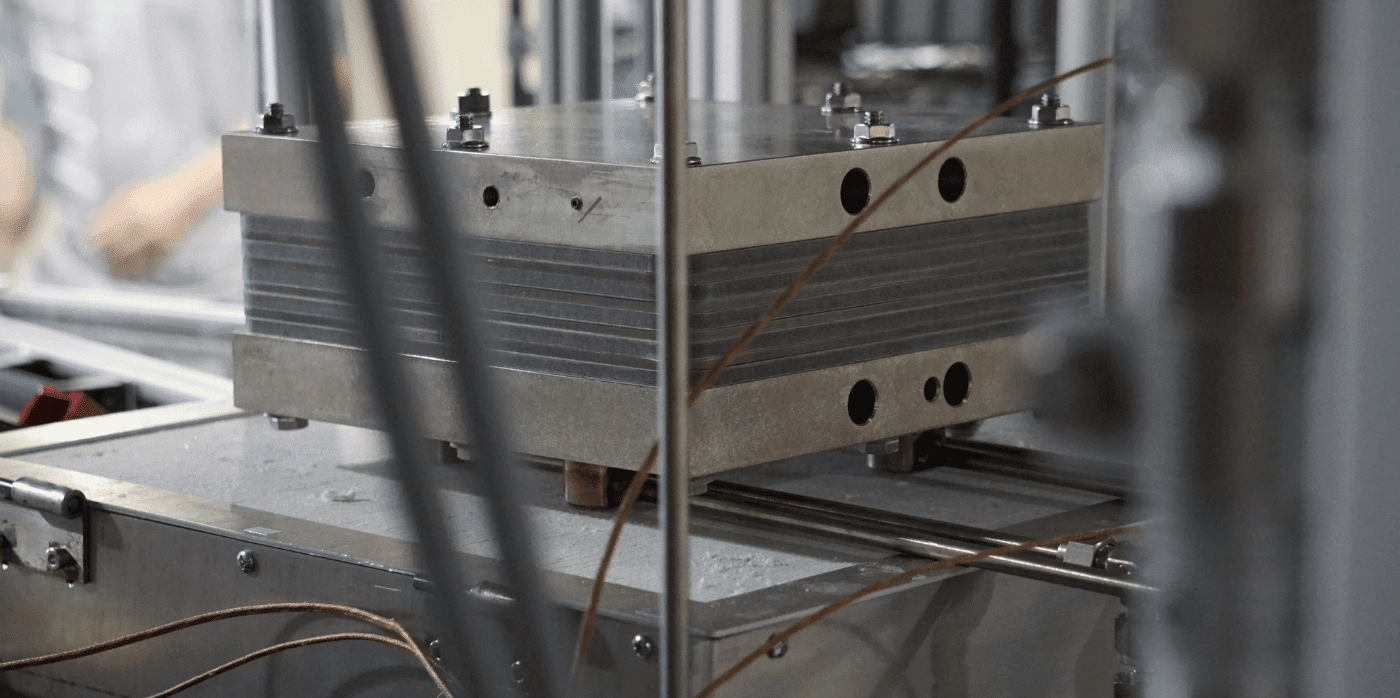

The company’s AC system is designed to replace the energy-intensive Packaged Rooftop Units used to cool commercial buildings. The system uses a liquid saltwater solution as a ‘desiccant’, which is a substance that removes moisture – like the silica bead packets used when shipping products to prevent damp.

First, air is passed over a thin layer of the dessicant, which absorbs moisture. The dried air is then split into two streams. The first air stream gets directed over a thin layer of water, which absorbs the air’s energy (heat) to leave it cooler. This cooler, now-humid, air cools a metal surface, before being funnelled outside. Finally, the cool metal sucks heat out of the second (still dry) air stream, which is then blown into the building. As well as cooling down the building, the system also dehumidifies it to improve indoor air quality and create a healthier indoor environment.

The dessicant will periodically need to release water and be ‘recharged’ for the system to keep working. Typically, this would require fossil-fuel-powered heating, but Blue Frontier instead uses a heat pump. This recharging can occur at night when electricity is cheaper and grid demand is lower.

Depending on weather or usage, the system reduces electricity use by 50 to 90 per cent and reduces peak electricity demand. The company points out that its AC system also enables the replacement of traditional ACs with an ‘HVAC-as-a-service’ business model that’s designed to speed up market adoption by removing the need for large capital investments.

Luckily, recognition of the huge energy footprints of heating and cooling systems is leading to a wave of innovations. These include more viable heat pumps and the use of geothermal energy.

Written By: Lisa Magloff and Matilda Cox