FMG’s New Stoneware Surfaces Deliver Incredible Design Flexibility for Architects

One of the most challenging aspects of design is bridging the gap between concept and reality. Architects and interior designers are first and foremost creatives; they are visionaries who at times struggle to find the perfect material that will bring their concept to life without some form of compromise. Whether it be a change in budget, an unforeseen roadblock or a disconnect between designer and developer, using materials that can easily adapt to a modified design ensures a successful outcome.

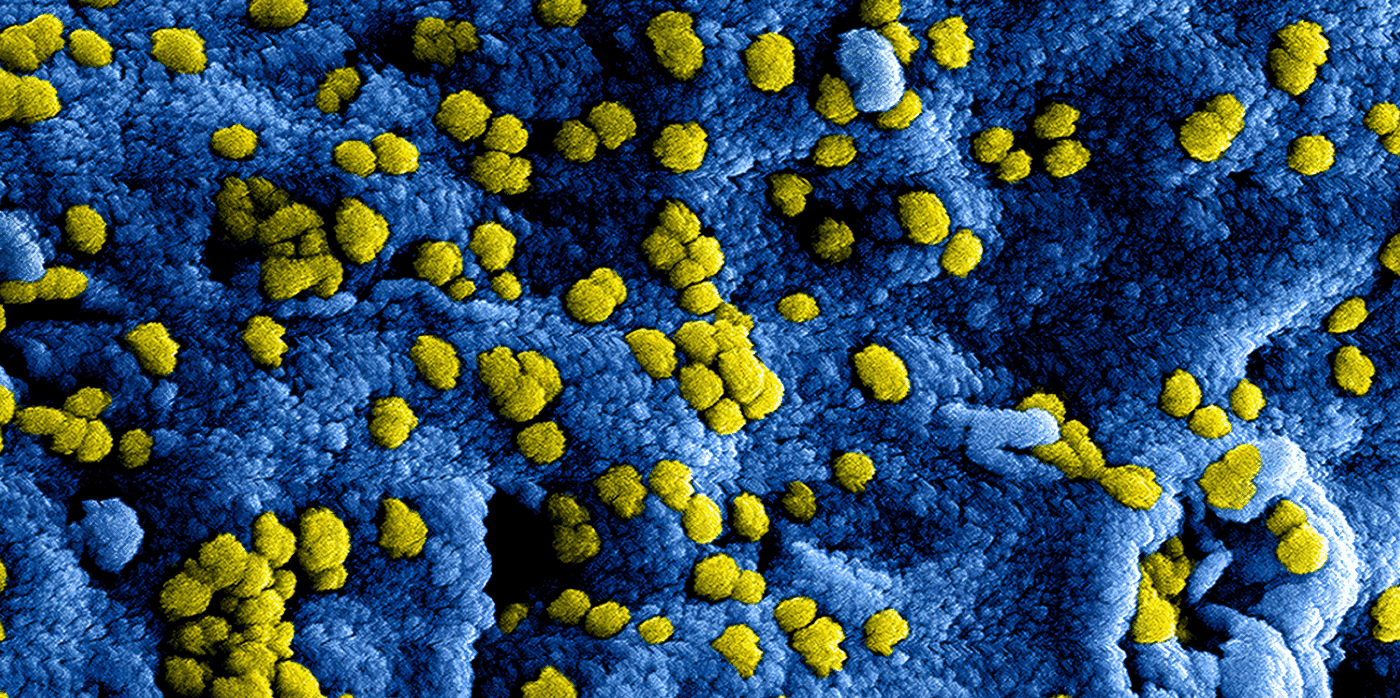

Fortunately, Italian stoneware Brand FMG Fabbrica Marmi e Graniti, part of Iris Ceramica Group, has developed a new product with creatives in mind. After extensive research and a thorough development process, FMG’s new full-body porcelain stoneware surfaces offer a comprehensive selection of durable, flexible and color-forward stone composites. Through a combination of raw materials, pigmented powders and random mix of hues, a robust line of handmade-like, unrepeated stone effect surfaces have recently hit the market. Among the most distinctive stone composites from the collection are the Palladio, the Venice Villa and the Rialto.

Project featuring FMG’s “Venice Villa” full-body porcelain stoneware

FMG boasts a unique production system that presses toxic-free powders with raw materials into an extremely durable material. The result is a compact stoneware that is non-absorbent, resistant to atmospheric agents and frost-free. Such a product can be easily implemented in both indoor and outdoor spaces as well as in private and commercial settings. Due to its extreme durability, it can withstand high-traffic environments without compromising aesthetics and functionality.

What further makes full-body porcelain stoneware stand out is its special processing abilities, enabling this stoneware to be manufactured for each designer’s bespoke needs. Whether the design requires rounded, beveled or central curved edges, the stoneware can be cut to deliver the required shape.

Project featuring FMG’s “Palladio” collection

FMG’s collection pays tribute to the Brand’s Italian origins through its experimentation and interpretation of the traditional and well-loved Venetian terrazzo flooring. Terrazzo has been around for centuries and has managed to remain a popular floor treatment to date. From its Venetian origins to its wide popularity in the Art Deco movement – it maintains its relevance in today’s dynamic design world.

A common complaint of terrazzo is its susceptibility to cracks if not properly maintained or if installed on a poor structural base. The full-body porcelain stoneware’s durable surface ensures a long-lasting, crack-free product that achieves the beloved terrazzo aesthetic. This built-to-last product can be implemented in a plethora of surface types – kitchen countertops, chairs, and shower trays – thus offering a product that is multifunctional and in many ways more versatile than traditional terrazzo.

Project featuring FMG’s “Rialto” full-body porcelain stoneware in zinc

Such versatility is not only seen in its physical makeup but in its pronounced and adaptable aesthetic. Through a thoughtful mix of marble fragments, grit sizes and stones, this line offers perfectly textured and decorative surfaces. Each style boasts a terrazzo-esque design, and whether the preference is a tighter pattern or a looser look, there are various options to choose from.

The line comes complete with 30 color offerings, ranging from ivory to graphite. The variation of finishes ensures the designer’s ideal aesthetic can be achieved, from Naturale, Levigata (smooth) and Strutturata (structured) to Sabbiata (sandblasted). The Palladio, Venice Villa and Rialto all come with a 10 mm (0.4 inch) thickness, with eight different sizes available. Among the Brand’s typical size offerings — 120×60, 60×60, 60×30 and 20×20 cm — three new formats join this collection: 150×75, 120×120 and 75×75 cm.

Project featuring FMG’s “Rialto” in pink

FMG’s full-body porcelain stoneware truly celebrates the spirit and colorful architectural history of Venice. Even its products’ names — Palladio, Venice Villa and Rialto — pay tribute to Venetian architecture. Rialto echoes the bustling Venetian commercial district and Venice Villa pays tribute to the region’s astounding mansions, while Palladio references the prominent Italian Renaissance architect, Andrea Palladio.

Very few products can offer such flexibility all the while ensuring a long-lasting, high-quality finish, with the need to compromise on aesthetics. As a modern-day interpretation of classic terrazzo flooring, combined with highly resilient material qualities, FMG’s latest stoneware collection is one that architects and designers can rely on to realize their creative vision.

To learn more about full-body porcelain stoneware and explore all of FMG’s offerings, check out their website.