Making food out of carbon dioxide

Spotted: The development of meat alternatives is moving forward at a rapid clip. From plant-based and cell-based meats to 3D-printed food, the market for animal-free meat alternatives is expected to grow rapidly in the coming years. Now, startup Arkeon Biotechnologies is adding a new method to this mix. The company uses a single-step fermentation process that turns ancient micro-organisms and captured carbon dioxide into the building blocks for food.

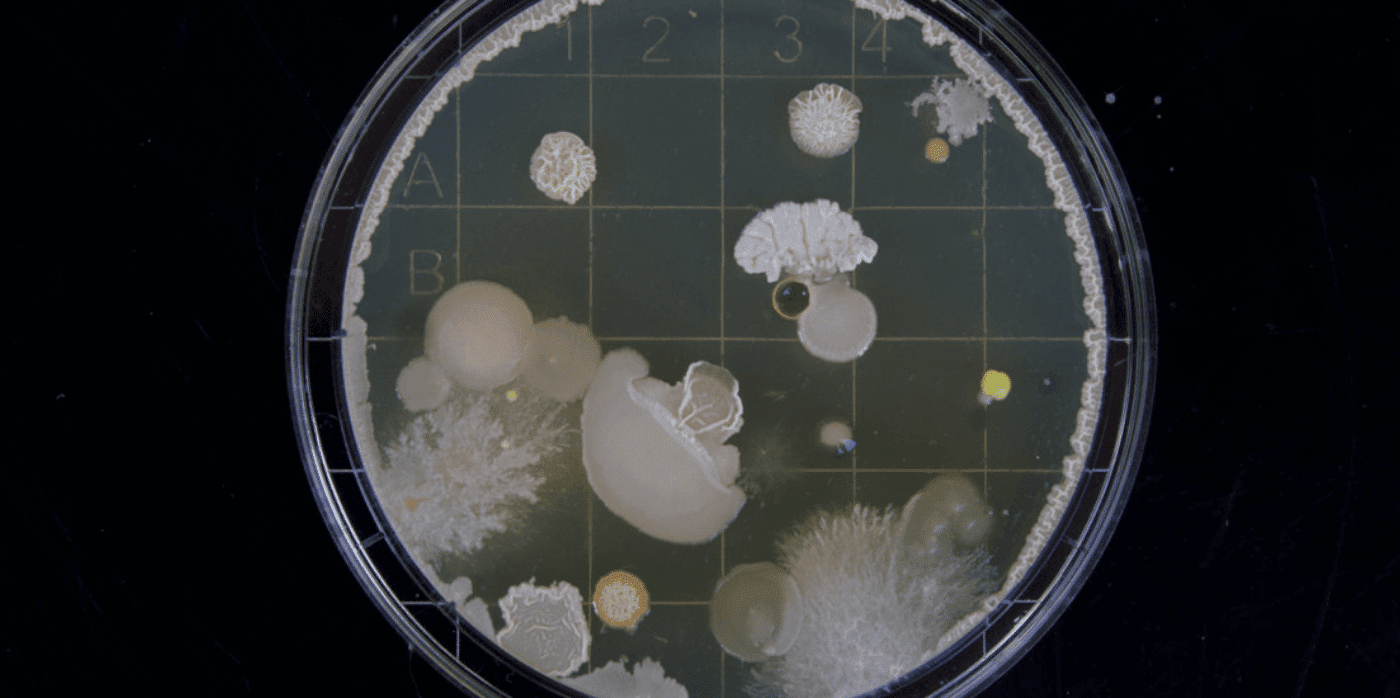

Arkeon has pioneered the use of Archaea, ancient organisms that evolved to survive in extreme settings, such as around underwater vents. The company uses a strain of Archaea that can makes all 20 essential amino acids and has developed a process to harness this ability in order to produce alternative protein products. The micro-organisms are fermented in bioreactors using CO2 captured from breweries. The process produces carbon negative ingredients that are then used to create meat-free foods.

Currently, many plant-based foods use proteins, such as pea protein, that are produced through purification and processing to remove unwanted flavour and add taste. Arkeon’s amino acid products, by contrast, require no purification or additives. The amino acids can then be combined to create tailored ingredients and products, such as meatless meats, or used to add nutrition to products such as infant formula.

Arkeon was founded by ‘company builder’ EVIG, which works with scientists to develop biotechnology startups in the food sector. EVIG brought together three scientists— Gregor Tegl, Simon Rittman, and Guenther Bochmann—to create Arkeon.

Other alternative protein innovations spotted by Springwise include artificial intelligence that helps to build animal-free proteins, and a foodtech startup that uses plant cells to create dairy proteins.

Written By: Lisa Magloff