A sparkly revolution in eco-friendly glitter

Spotted: As most parents can tell you, glitter is something of a scourge – it gets everywhere and is very difficult to clean up. It is also an environmental nightmare — made from plastics, metals, and dyes, it is essentially a microplastic and easily enters the food chain. Some of the materials used to colour glitter are also toxic. In fact, Europe has already banned titanium dioxide, a compound often used to colour glitters, from use in food products.

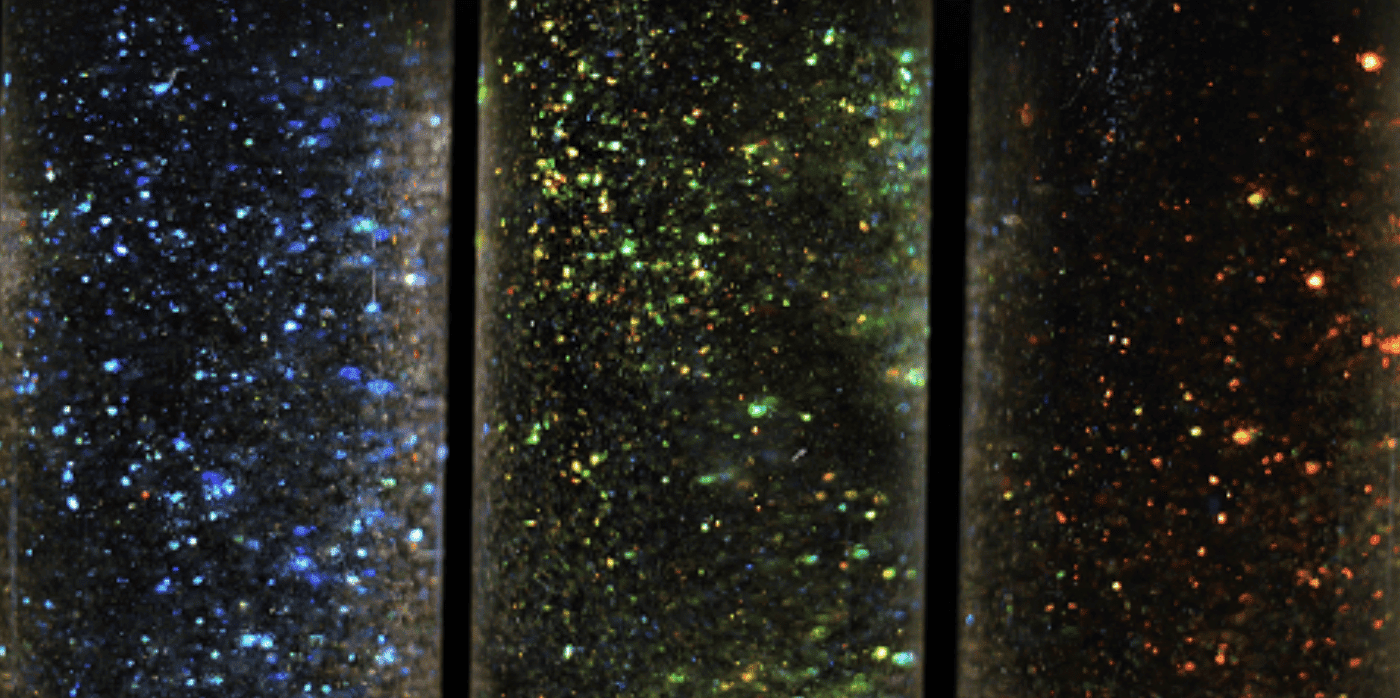

Startup Sparxell is working to make glitter safer for everyone by using plant-based pigments specially designed to deliver the intense colours and bright shine needed for glitter and sequins. The biodegradable pigments are made from cellulose nanocrystals, which form helix-like structures that reflect light, in a similar way to how birds and butterflies achieve their bright colours.

To make the glitter, the crystalline part of cellulose is extracted and dispersed in water. On drying, the crystals form a film that reflects light and colour over a large area. The film can then be ground into a range of sizes and shapes to produce glitter. By controlling the interactions between the crystals, Sparxell can tailor-make the crystals to match a specific appearance.

Sparxell was spun out of Cambridge University and is currently seeking to raise a $2 million (around €1.9 million) seed round of funding. The money will be used to scale up production to deliver large quantities of the product.

Sustainable glitter joins a host of other eco-pigments. Recent innovations spotted by Springwise range from eco-paints made using graphene to low-heat, low-energy bio-pigments.

Written By: Lisa Magloff