ZeroAvia test-flies largest plane yet powered by hydrogen-electric engine

ZeroAvia has flown what the aviation company claims is the largest aircraft yet to be run on a zero-emissions hydrogen-electric engine, testing a 19-seater plane over the skies of England.

The company flew a modified 19-seat Dornier 228 twin-engine aircraft with one prototype hydrogen-electric engine retrofitted on its left wing and a regular gas turbine engine, a Honeywell TPE-331, on its right wing.

The test flight saw the plane take off, fly and land at ZeroAvia‘s R&D facility at Cotswold Airport in Gloucestershire on 19 January.

According to ZeroAvia, the flight shows the British-American company is on track to run its first hydrogen-powered commercial flight by 2025, with the aim of eventually scaling up the technology to larger planes.

“This is a major moment, not just for ZeroAvia but for the aviation industry as a whole, as it shows that true zero-emission commercial flight is only a few years away,” said ZeroAvia founder and CEO Val Miftakhov. “Our approach is the best solution to accelerate clean aviation at scale.”

ZeroAvia uses hydrogen fuel cells, one of two major hydrogen-based technologies being explored for flight along with the hydrogen combustion engine.

In fuel cells, hydrogen is used to produce electricity and that electricity powers the propeller, instead of the hydrogen being burnt like in a combustion engine. The process generates no emissions besides water vapour.

ZeroAvia deployed its prototype engine in a testing configuration that featured two fuel cell stacks along with lithium-ion battery packs to provide extra support for takeoff and backup power.

The fuel cells and hydrogen tanks were housed inside the cabin of the plane, where the seats would usually be. But eventually, they will need to be stored externally.

The company conducted the flight test under what it describes as the “stringent” requirements for a Part 21 aircraft flight permit with the UK’s Civil Aviation Authority, which the company says signals its readiness for commercial certification.

ZeroAvia says that under these conditions, the test flight places the company on the direct path to a certifiable configuration to be finalised and submitted for approval in 2023.

ZeroAvia is one of the current leaders in the race to develop hydrogen engines to decarbonise plane travel. The prototype tested was developed as part of the company’s HyFlyer II project, which is supported by the UK government’s Aerospace Technology Institute and targets the development of a 600-kilowatt powertrain.

Simultaneously, the company is also developing a two-to-five megawatt powertrain that scales the technology for aircraft with up to 90 seats.

Hydrogen engine technology is evolving rapidly, with many airlines and aerospace companies engaged in development and testing.

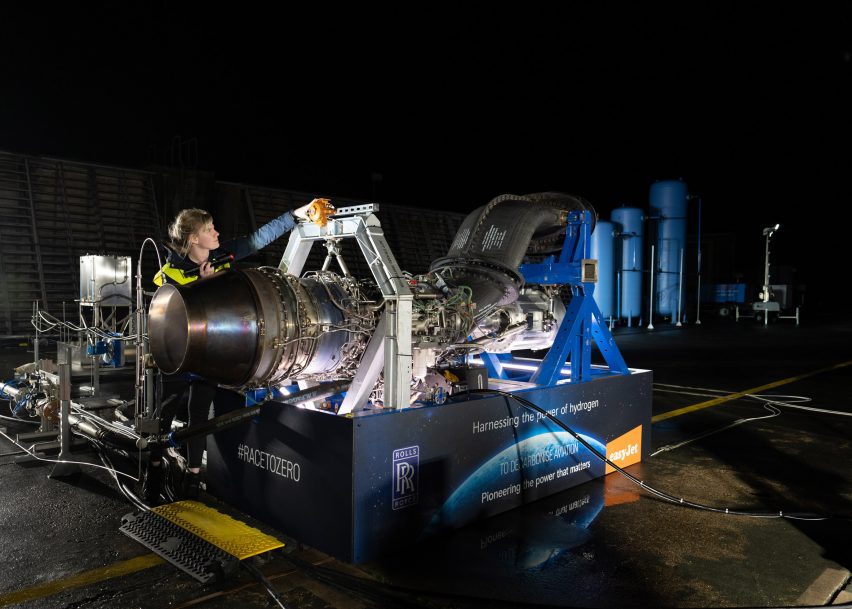

Recently, EasyJet and engineering company Rolls-Royce conducted a ground test of a modified commercial aircraft engine run on hydrogen combustion, while Airbus has previously revealed three concept designs for hydrogen-powered aircraft.

A challenge for the technology is the size of the hydrogen tanks required, which has made critics doubt that it can ever be used for jet planes or long journeys.