Harnessing power through existing ocean infrastructure

Spotted: Depending on what source you use, the total estimated output of global wave energy is somewhere between 20 and 90,000 terawatt-hours per year. Although this is a wide range, when you consider that the total global energy consumption is now over 25,000 terawatt-hours per year, even the low end of the range is enough to cover most of humanity’s energy needs. The main issue, however, is finding the best way to take advantage of this wave energy.

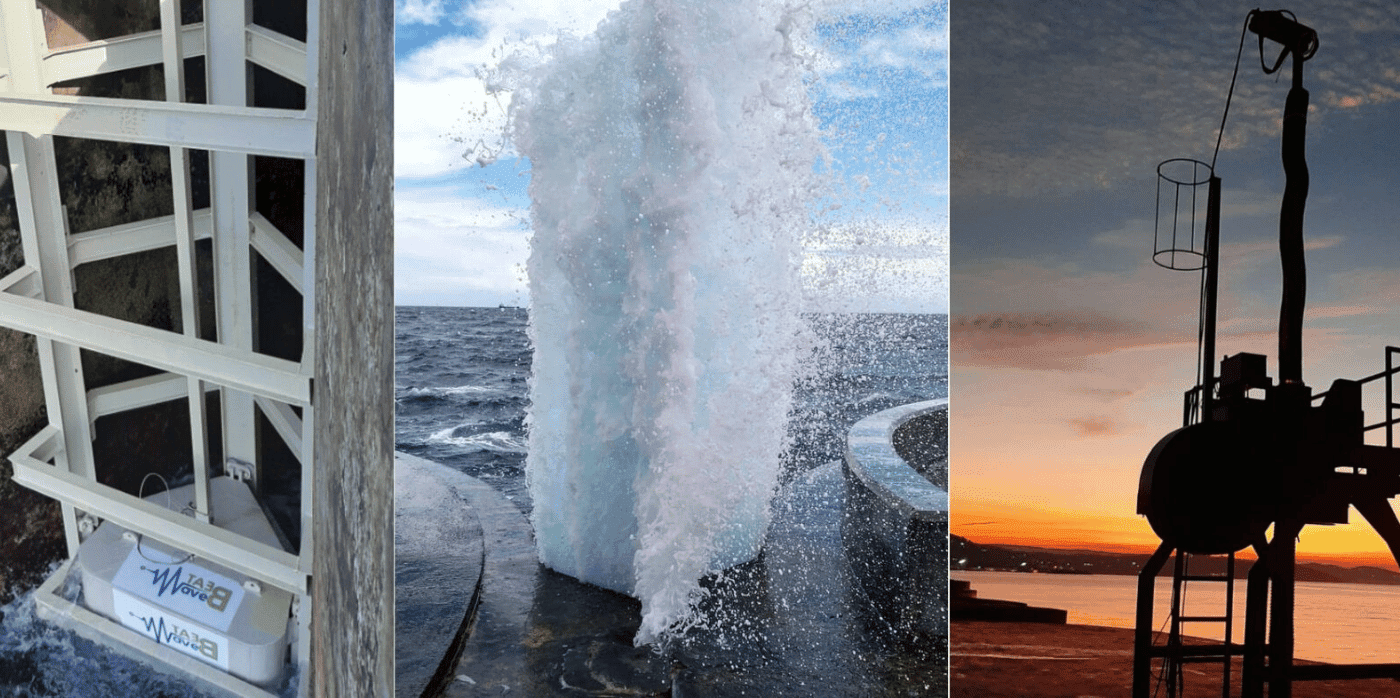

Moroccan startup Advanced Third Age Renewable Energies Company (ATAREC) is developing a system to exploit the wave energy close to shore, in the areas around breakwaters and other infrastructure exposed to the sea. The startup’s Wave Beat technology captures energy from the vertical variations in sea level using a free-floating buoy.

ATAREC has constructed a demonstrator in the Port of Tanger-Med, 45 kilometres north of Tangier, to take advantage of the 110 megawatts of wave energy in front of the port’s vertical breakwater. The energy produced by the Wave Beat is used directly at the huge port to help run operations.

The company has received more than €900,000 in funding, including equity, grants, and non-dilutive funding. ATAREC is currently applying for additional funding and plans to launch a fundraising campaign.

Wave energy is starting to take off, with other innovations spotted by Springwise including a design for generating energy from the movement of ships in the water and rolling wave generators to power sensors.

Written By: Lisa Magloff