Kit Switch Accelerates Interior Rehabs

The United Nations estimates that the world will add about 2.6 trillion sqft of new floor area to the global building stock. This equates to adding an entire New York City, every month, for 40 years. A large proportion will be housing. Specifically, housing is needed in already dense urban areas and existing structures. So the way we build and maintain our housing stock needs to change drastically.

- Renovating existing and functional buildings takes time. Yet the US has 44 million multifamily units. A full 50% were built before 1980.

- Rehabilitating vacant and obsolete buildings seems cost prohibitive. Yet, the US has 6 billion sqft of commercial real estate sitting vacant.

- New construction has improved in energy efficiency. But current designs do not sufficiently address the need for easy maintenance and future rehabilitation.

How can these time and cost challenges be solved? By creating standardized, simpler processes.

Simpler means faster

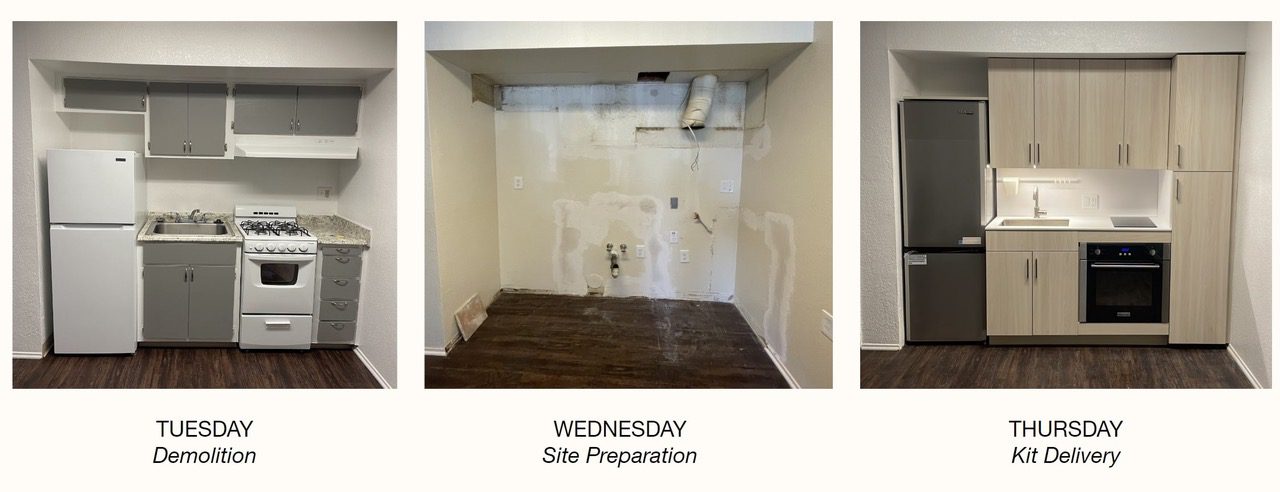

Kit Switch, a California-based, women-owned construction business, offers a simple approach to designing and constructing apartment interiors. Kit Switch replaces fragmented, uncertain, and time-consuming on-site retrofit processes with an end-to-end, design-build solution. These modular systems for apartment interiors streamline existing building rehabilitations and new construction build-outs.

Rehabilitating and retrofitting existing residential buildings will significantly reduce ongoing emissions. This will include replacing inefficient and gas-powered appliances with electric ones and making homes more energy efficient through weatherization and other upgrades. The overall mission of Kit Switch is to help close the housing gap through sustainable building reuse.

The products are kits-of-parts, ready-to-install apartment interiors, such as kitchen and bathroom kits. The company manages a digital library of components. Architects drag-and-drop 3D models to instantly generate layouts and quotes. Local manufacturers produce the modules concurrently with on-site work. Then contractors install and connect products in a few hours instead of weeks of site coordination.

Kit Switch benefits housing, both new construction and rehabs:

- streamlines schedules from design through coordination and construction

- cuts on costs, especially on prevailing-wage projects

- offers a more sustainable and durable alternative to traditional interior builds

With durable materials and low-waste assembly, they expect to reduce embodied carbon by a third, compared to traditional on-site construction.

Kitchens first

Kit-Kitchen is the first product to debut. It comprises three standard products: Kit-Cook, Kit-Clean, and Kit-Store. This modular system for kitchen installations is assembled on-site in less than 1 day, compared to 4 to 5 days of labor for a traditional install. The innovative design consolidates plug-and-play electrical and plumbing systems inside the kits. This further reduces drywall, plumbing, and electrical work.

And while Kit Switch products are standard, the system is modular. So developers can customize the design needed for each project.

Kit Switch was formed as a public-benefit corporation, with a mission statement around affordability, sustainability, and opportunity. Co-Founders Armelle Coutant and Candice Delamarre envision a future where cities can achieve greater circularity and resiliency. Easily deployable and reconfigurable building interiors better meet the housing needs of communities.

Kit Switch is partnering with affordable housing developers across California to support ground-up and acquisition-rehab projects. Asset managers seek out Kit Switch to meet renovation and maintenance needs. The potential impact for the Los Angeles region was recently recognized with the Trailblazer Award from USGBC-LA.

USGBC-LA Net Zero Accelerator

Kit Switch joined the 2023 cohort of Net Zero Accelerator (NZA) in 2022. Since then, the team has exhibited at the MyGBCE conference, Net Zero Conference, and VERGE, sharing their work with the green building industry and generating leads for pilot projects based in the Los Angeles area.

The NZA, a program of the U.S. Green Building Council–Los Angeles (USGBC-LA), pairs cohort members with expert advisors, promotes their solutions to high value prospects, and places pilot projects. The goal is to help these growing companies better prepare for scaled adoption.

Since its founding in 2018, the accelerator has guided the success of 85 growth-stage companies in the cleantech space across the US and Canada. The accelerator leverages the insights, expertise, and relationships of partners and community members to speed the development and commercialization of sustainable innovations. The program brings thought leadership and broad awareness to high-potential pilot projects. It is the only one of its kind focused on the built environment. Targeting solutions for net zero carbon, energy, water, and waste, the program advances building decarbonization, occupant wellness, sustainable infrastructure, and clean construction.

The author:

Candice Delamarre is the Co-Founder and COO of Kit Switch, a women-owned construction company that has developed a modularized system for apartment interiors. Kit Switch streamlines schedules, cuts costs, and improves durability for multifamily housing developments and rehabilitations. Delamarre has long been passionate about circular and sustainable practices, and equitable access to housing. Before Kit Switch, she worked as a strategy and sustainability consultant to real estate and corporate stakeholders. Delamarre holds a master’s in civil engineering from École Centrale Paris and a master’s in Sustainable Design & Construction from Stanford University.

Our team researches products, companies, studies, and techniques to bring you the best of zero building. Zero Energy Project does not independently verify the accuracy of all claims regarding featured products, manufacturers, or linked articles. Additionally, product and brand mentions on Zero Energy Project do not imply endorsement or sponsorship unless specified otherwise.