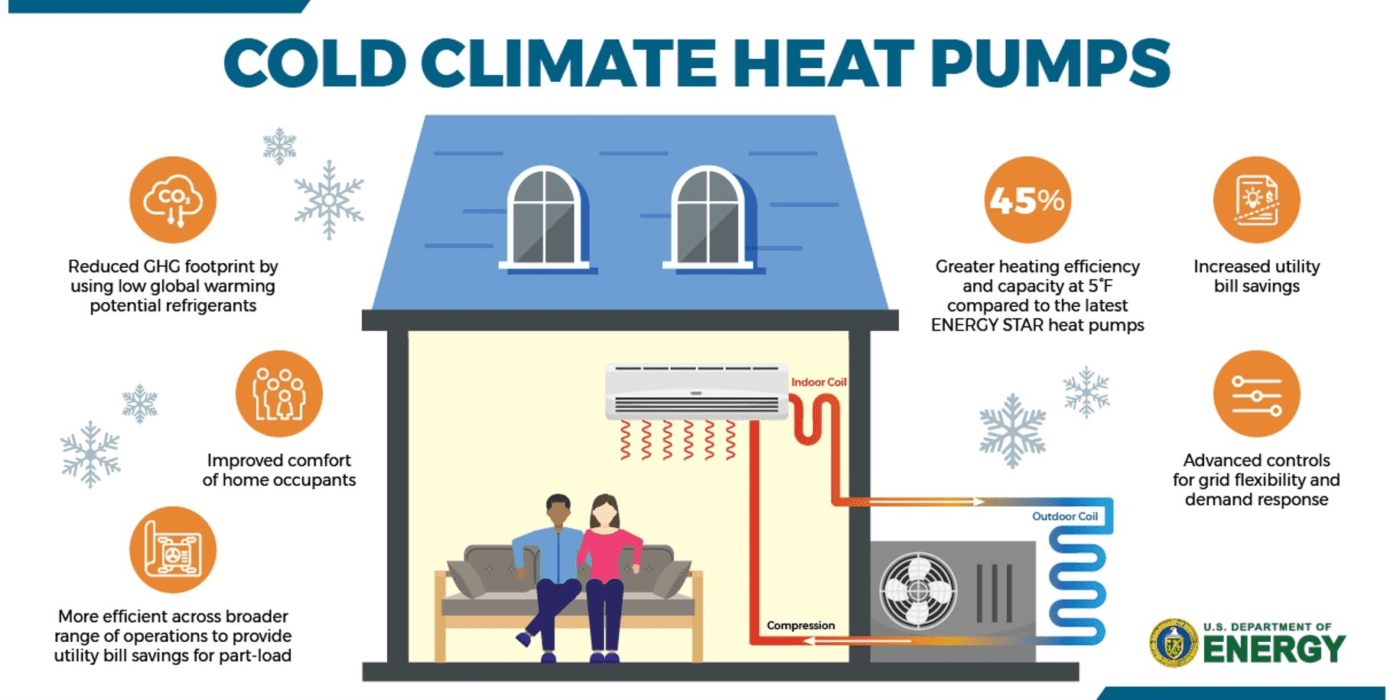

In the US, about 13% of total CO2 emissions come from heating residential and commercial buildings. Because so many buildings rely on natural gas and heating oil, significant opportunity for reducing heating emissions lies with electric heat pumps. Heat pumps have been popular in the South for decades, but there are a lot of questions about how well they work in colder climates.

“A huge portion of our global emissions come from heating buildings,” says Brian Stewart, co-founder of Electrify Now, a volunteer organization devoted to electrification. “Since our homes are a big part of that, it’s important for us to understand the options we have for zero-carbon heating.”

Recently, researchers from the University of California, Davis did the math on switching from a gas furnace to an electric heat pump. Even with the mix of fuels that currently powers the electrical grid, a heat pump will produce far fewer emissions than a gas furnace, no matter where in the US you live. As the grid gets cleaner, the difference between electric and gas heating emissions will only continue to grow.

“We know that electrification works from a decarbonization standpoint, and we know that these heat pumps work in many situations,” says Stewart. “But we still have so many people wondering: Will heat pumps work in cold temperatures?”

Heat pumps, not just for warm climates

“With a standard heat pump, you start to lose efficiency as temperatures dip below 40°F,” explained Shawn LeMons, Performance Construction Manager for Mitsubishi Electric Trane HVAC US. “So, the system needs more electric power to extract heat from colder air.”

That’s where cold climate heat pumps come in.

Also known as high-efficiency heat pumps, these high-tech systems are specially designed to operate at a higher heating capacity in lower temperatures. “Cold climate heat pumps may look similar to standard heat pumps, but their internal technology and computer programming are far more advanced,” LeMons added. “They’re specifically built to function at subzero temperatures, all while operating as efficiently as possible.”

Location, location, location

Cold climate heat pumps are purpose-built for heating comfort and ease of use in inclement weather. You can use them in any “heating-dominated” region where HVAC systems spend most of the time heating instead of cooling. This includes climates with frequent snow and ice, as well as coastal climates with cold rain and fog. As long as your system is operating properly, it should be able to handle prolonged subzero temperatures, even at elevations thousands of feet above sea level, explained LeMons.

Households in milder temperature zones may also prefer a cold climate heat pump when the weather outside starts to get snowy or icy. You may not necessarily need a cold climate heat pump year-round, but having one will give you added benefits and comfort during the cold winter months.

Buying a cold climate heat pump

“Generally, because of the special features and programming, cold climate heat pumps can cost around 20% to 30% more than standard heat pumps,” said Jonathan Moscatello, Business Development Manager for Daikin North America. That’s because you’re paying for the system’s ability to pump heat in colder temperatures, and that’s where cold climate heat pumps shine.

“Compared to traditional heat pumps, they produce more heat per dollar spent, making them a better value in the long run,” said Moscatello. And that’s before you consider the potential tax incentives you’ll get when you make the switch!

Take note: Some manufacturers put all their premium technology into their cold climate models, so you’re also paying for features unrelated to the cold climate performance, Moscatello pointed out. So don’t be afraid to shop around for the best value.

What should you look for when picking out a cold climate heat pump? It depends on whom you ask. Start with the EnergyStar and Northeast Energy Efficiency Partnerships (NEEP) published standards for cold climate heat pumps. Most utility and government rebate programs also use these specifications.

“Manufacturers also have their own standards for what qualifies a heat pump for cold climate operation,” added Moscatello. “Examples of this include Mitsubishi’s Hyper-Heat line and Daikin’s Aurora line.”

Ratings and features to look for

LeMons and Moscatello recommend the following guidelines when shopping for a cold climate heat pump:

- Rated performance at 47°F.

- Maximum performance at 5°F.

- Capacity ratio at 5°F. This is the ratio of #1 and #2 above; the closer this number is to 100%, the better it can handle very low temperatures.

- Coefficient of performance at 5°F You want this number to be below 2. The lower the number, the better the system’s heat efficiency.

- Published performance at very cold temperatures, such as -13°F, -15°F, or -22°F. Keep in mind that these numbers give an idea of how the heat pump will perform on the coldest days. Many systems continue to work well at even lower temperatures.

Some typical features to look for:

- Inverter compressors and advanced motors for greater energy efficiency

- Advanced programming for cold climate operations, such as hot discharge air temperatures and “just right” airflow

- Intelligent defrost cycles and drain pan de-icing

- Optional wind baffles for an outdoor unit

At the end of the day, you’re buying a heating appliance, and you want to make sure it’s purpose-built for cold winter comfort. So, definitely read reviews and ask around before you buy!

The US Department of Energy’s Residential Cold Climate Heat Pump Technology Challenge is working with manufacturers to develop next-generation electric heat pumps.

Busting heat pump myths

Myth #1: You need a backup system to handle the coldest winter temperatures.

“Dual fuel is a legitimate path, but it’s not really necessary with a cold climate heat pump,” explained Stewart. Sure, standard heat pumps may need an alternate heating source like a furnace or boiler to take over when temperatures drop below freezing. Cold climate heat pumps, on the other hand, are equipped to handle the most frigid winters.

Laura Martel, Research and Evaluation Manager for Efficiency Maine offered an example of cold climate heat pump performance. “Caribou is a town in northeast Maine that’s IECC zone 7, the coldest climate zone in the United States. Homes in Caribou need their heaters for 6,444 of the 8,760 hours in a year.”

According to data from Efficiency Maine, it’s cheaper and more efficient to heat a home in Caribou with a cold climate heat pump than with a dual fuel system, natural gas, propane, or oil. While natural gas or propane systems may become more efficient when outdoor temperatures drop below 0°F, that only accounts for around 500 total hours each year in Caribou. Therefore, natural gas is more efficient than heat pumps only 5% of the time. For propane, that number drops to 1%.

“When you look at annual operating costs for various systems, heat pumps save people between $1,000 and $3,000 or more per year. Even if you switch to natural gas or propane for the small fraction of time that they’re cheaper, you’d only save an additional $26 per year, max,” said Martel. So, even though cold climate heat pumps may cost around $2,500 more to install than boiler systems, the yearly cost savings can quickly add up to make up for that initial expense.

Myth #2: Turning down the heat at night saves energy.

“We’ve been told for decades that we should turn down our home heater systems when we’re sleeping to save energy. That works great for boilers and furnaces, but I wouldn’t recommend it with heat pumps,” says Martel.

While furnaces can quickly blast heat into your home, heat pumps take longer to raise the temperature. When you turn your heat down at night, you reduce the rate of heat output of your system, temporarily lowering your energy usage. But when you turn it back up in the morning, your heat pump has to work extra hard to get the temperature back up. It doesn’t help that it’s usually colder in the early morning.

“Turning the heat down or off at night just isn’t as efficient as picking a comfortable temperature, setting it, and leaving it alone,” she said.

Still have questions?

If you’re interested in learning more about heat pumps, check out Electrify Now’s electrification fact sheet. You can also use this savings calculator from Rewiring America to estimate the tax incentives you’d receive from installing a heat pump in your home. Note that this article springs from Electrify Now’s cold climate heat pumps webinar, so check out their YouTube channel for more eco-friendly tips and technologies.

By Catherine Poslusny