Can we attract a greener future with rare-earth-free magnets?

Spotted: Magnets made from rare earths have become ubiquitous in several high-performance technologies and products ranging from wind turbines, electric vehicles (EVs), consumer electronics, and robots. However, while rare earth elements are essential for critical infrastructure, China controls the bulk of the supply chain, making the magnets subject to geopolitical tensions.

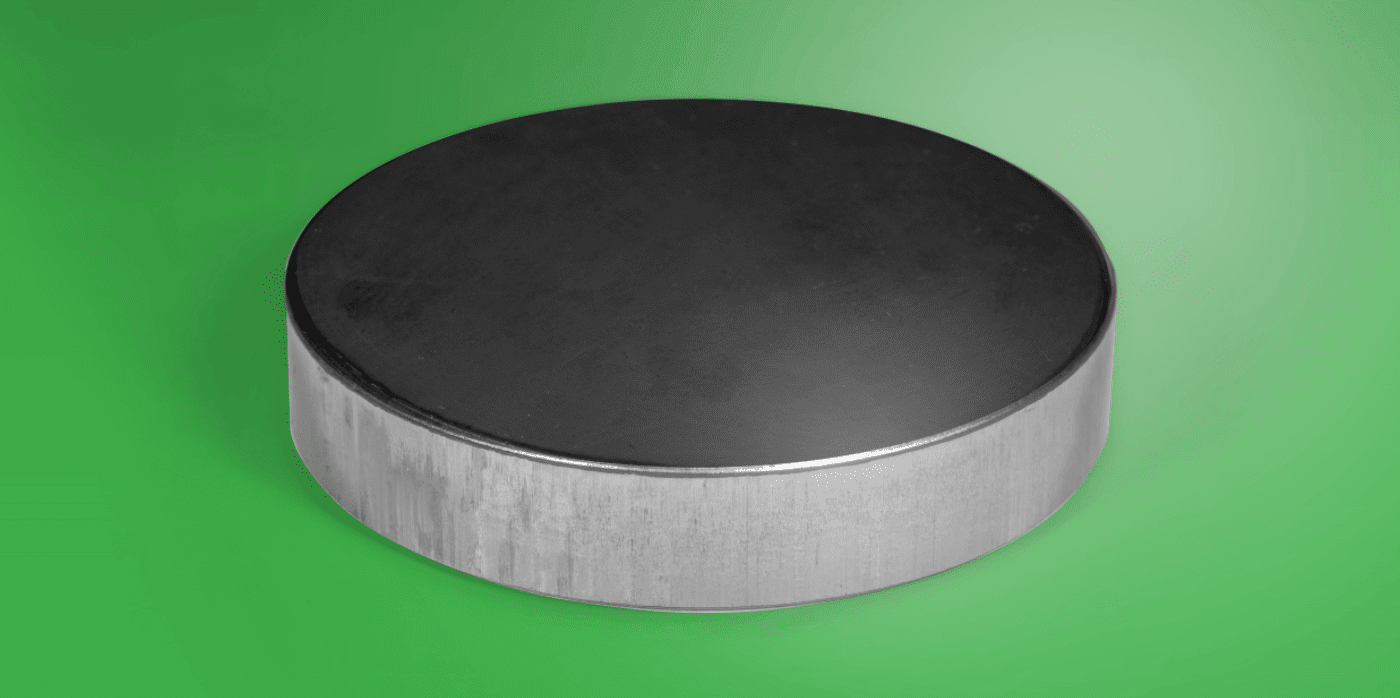

Now, Niron Magnetics has developed a high-performance permanent magnet that is as strong as a rare earth magnet but does not use any rare earth elements. Instead, the company’s Clean Earth Magnet is produced using abundant and easily recyclable materials (iron and nitrogen).

Not only do Niron’s magnets exceed the performance of rare-earth-based magnets by up to 50 per cent, according to the company, but they also have a 75 per cent lower overall environmental impact. Additionally, the Clean Earth Magnet is stable over a wide range of temperatures and, helped by the company’s scalable manufacturing processes, can be produced at a lower cost than those made from rare earths.

Niron’s magnets were recently selected as one of TIME Magazine’s Best Inventions of 2023, and TIME is not the only one excited by this technology. The company has forged commercial partnerships with companies like Volvo Cars, General Motors, Tymphany, and Western Digital.

Earlier this month, Niron announced an additional $33 million (around €30.4 million) had been raised, from investors including GM Ventures and Stellantis Ventures. This new financing will help the company scale its manufacturing capacity to support exclusive customer programmes and the first sales of its Clean Earth Magnet.

Replacing new rare earth elements is the goal of recent innovations that include the use of ferrite magnets in wind and tidal generators and the recycling of rare earth elements from products such as flat-screen TVs.

Written By: Lisa Magloff