Can You Really Grow a City? The Truth About Mycelium

Architizer’s 12th Annual A+Awards are officially underway! Sign up for key program updates and prepare your submission ahead of the Final Entry Deadline on January 26th.

The architecture industry is looking for alternatives to concrete, the world’s most widely used building material. Cheap, versatile and strong, concrete is one of the most revolutionary substances in history. It would not be an exaggeration to say that cities as we know them today would not have been possible without reinforced concrete. However, the carbon footprint of cement production is enormous, accounting for 8% of global emissions each year. For comparison, this is a far higher share than the aviation industry, which is responsible for 2% of emissions. It is not hard to see why architects are interested in moving away from concrete — and quickly.

Among the alternatives to concrete being researched, a material derived from fungus called mycelium is by far the most romantic. In 2024, everyone knows someone obsessed with mushrooms and their alleged nutritional, medicinal and psychotropic virtues. For these types, it just makes sense, in an artistic or spiritual way, that fungi will rescue us from the climate crisis we’ve created.

I mean this with no condescension whatsoever: fungi are fascinating and inspiring. They have also been around far longer than animals and plants. Personally, I adore the idea of a future world where we live in homes made of mycelium. There is an undeniable Richard Scarry-esque charm to the image of living inside a mushroom.

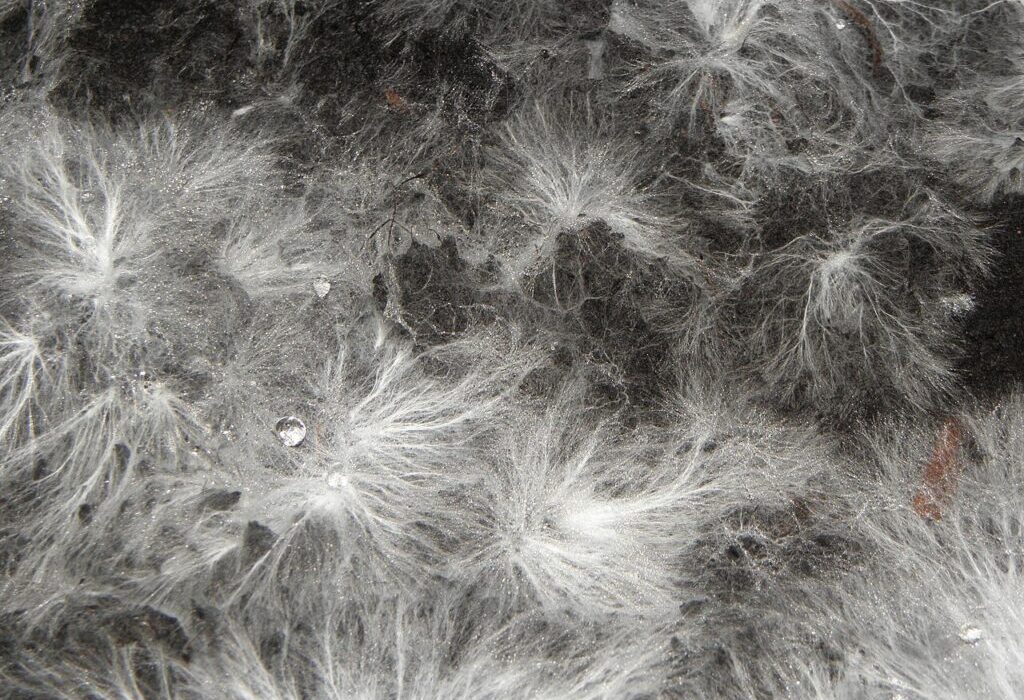

Close up of mycelium network. Rob Hille, Mycelium RH (3), CC BY-SA 3.0

So what exactly is mycelium? Briefly, mycelium is the root-like structure of a fungus. It functions both as a root system as we would think of it — that is, a fungus transports nutrients through its mycelium — but also as a kind of giant brain. The mycelium of a fungal system sends electrical signals to different parts of the organism to warn of changes in the environment.

In some cases, a mycelium system can span thousands of acres, as is the case in Oregon’s Malheur National Forest. Individual mushrooms are simply the “fruiting bodies” of this vast organism, which is estimated to be at least 2,400 years old.

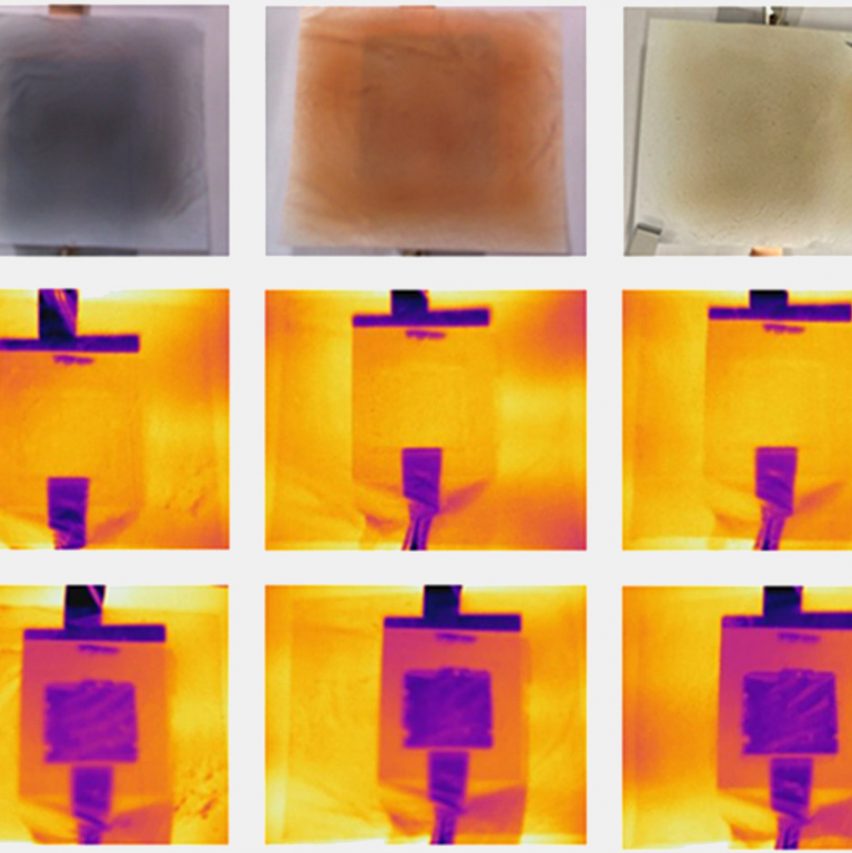

Mycelium is widely used in the world of packaging, with companies like Ikea and Dell using it instead of polystyrene, which is not biodegradable. The process for creating mycelium packaging is the same as for creating mycelium bricks, which are used for building.

First, organic waste is cleaned and then combined with mycelium, which grows around the waste and digests the material. (Remember: fungi eat their nutrients like we do. They are actually more closely related to animals than plants biologically). Then, the remaining material is placed into a mould. It continues to grow to fit the shape of the mould, and when it is dried, voila! A mycelium brick is born. This process is quick, taking only five days.

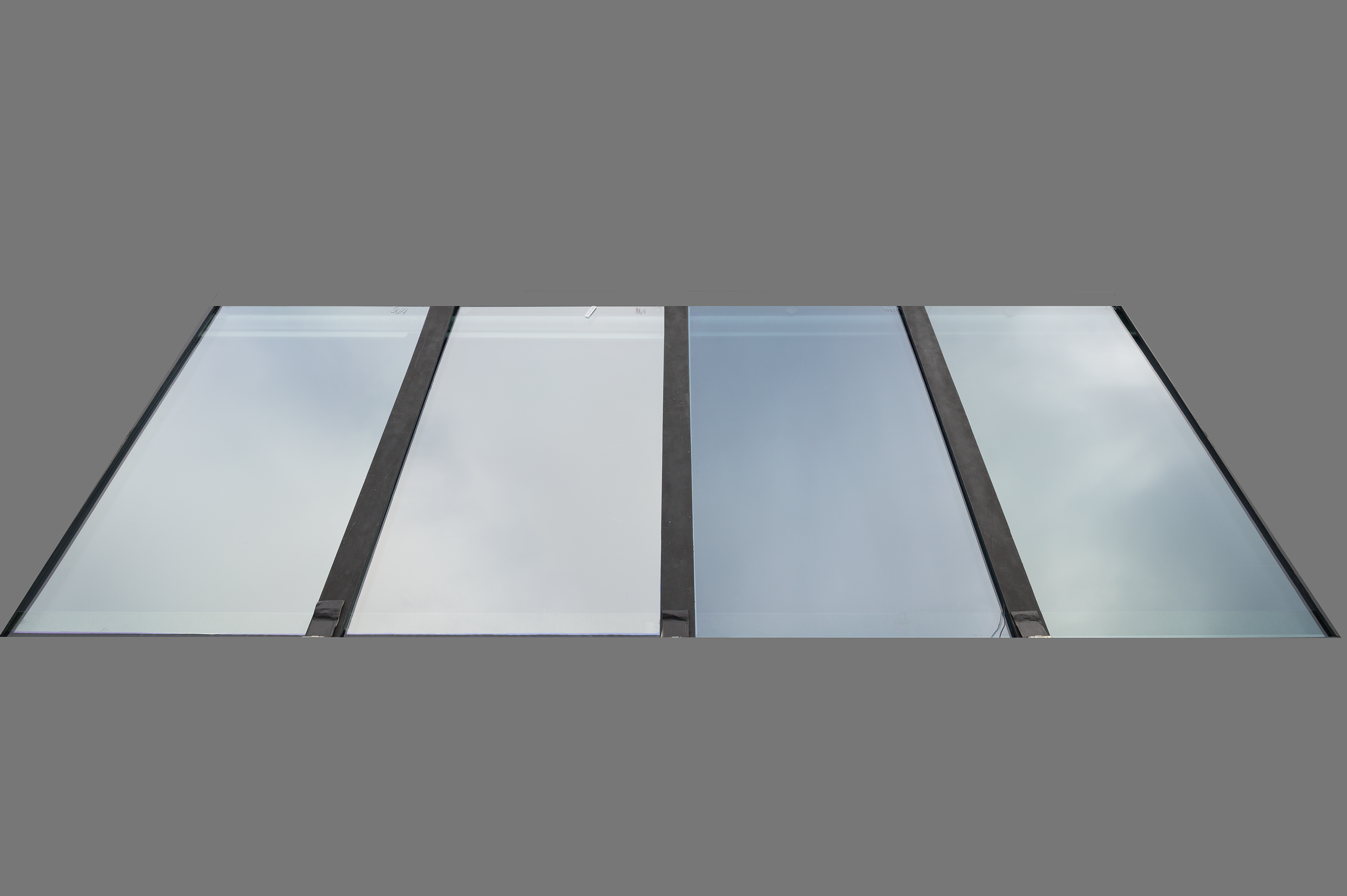

The Growing Pavilion by Biobased Creations, Eindhoven, Netherlands, 2019. Finalist, 2021 A+Awards, Architecture +New Materials

Certified Energy, an environmental consulting firm in Australia, aptly describes the virtues of mycelium construction: “Through bio fabrication a carbon neutral building process can be achieved eliminating such products as artificial insulation used in walls, MDF and other non load bearing structures.” In addition, “Mycelium products can also provide other benefits such as termite proofing, with products being created which attract termites but when eaten cause a fungus spore to activate within the termite killing it and creating a fungus whose spores repel other termites.”

Stunningly, Certified Energy explains that “relative to its weight a mycelium brick is stronger than concrete with a cubic meter of mycelium brick weighing 43 kilograms and a cubic meter of concrete weighing 2400 kilograms” (95 pounds versus 5,290 pounds). Unfortunately, this is not the most relevant metric. By volume, rather than weight, mycelium has nowhere near the compressive strength of concrete, clocking in at 30 pounds per square inch versus 4000 pounds per square inch for concrete. These bricks will not be used to build a home near you in the near future.

Hy-Fi by The Living, New York City, New York

And yet, there is still something inspiring about mycelium’s capacities. In 2014, The Living New York exhibited a tower called Hy-Fi in front of MoMA PS1. Standing 43 feet (13 meters) tall, the structure was made of 10,000 compostable mycelium bricks. As mycelium bricks are created through the process of organic decomposition, the manufacture of the bricks for this tower resulted in fertile soil as an output, which is obviously vastly preferable to the carbon released in cement production. Indeed, The Living New York donated this soil to local community gardens.

Another incredible feature of mycelium bricks: they are technically still alive when they are used. This allows them to bond to each other without mortar and even heal themselves when cracks appear. Can you imagine? A crack in your wall healing on its own.

Mycelium is certainly cool, and shows promise as a material for insulation, furniture, and the construction of temporary structures. However, it is unfortunately not a realistic alternative to concrete or even wood. Researchers should consider the way mycelium elements can complement sustainable architecture rather than pitching it as a building material on its own.

Cover Image: Mushrooms by Bernard Spragg. CC BY-SA 3.0 via Negative Space.

Architizer’s 12th Annual A+Awards are officially underway! Sign up for key program updates and prepare your submission ahead of the Final Entry Deadline on January 26th.

images courtesy Kengo Kuma & Associates

images courtesy Kengo Kuma & Associates