Built To Last: 6 Times ABC Stone Provided Rare Rocks for Timeless Architecture

Architizer’s A+Product Awards has officially launched! Get your products in front of the AEC industry’s most renowned designers by submitting today.

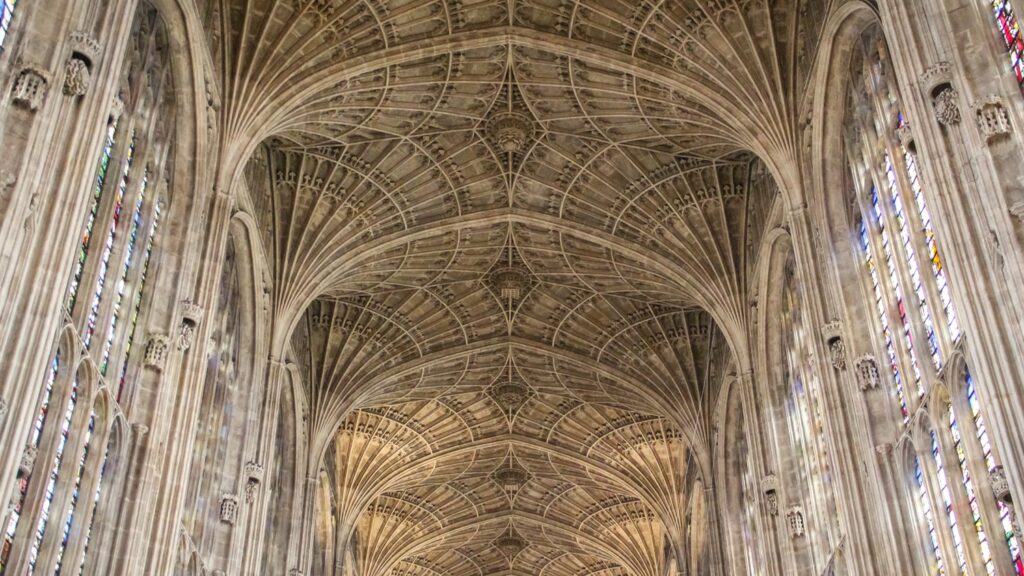

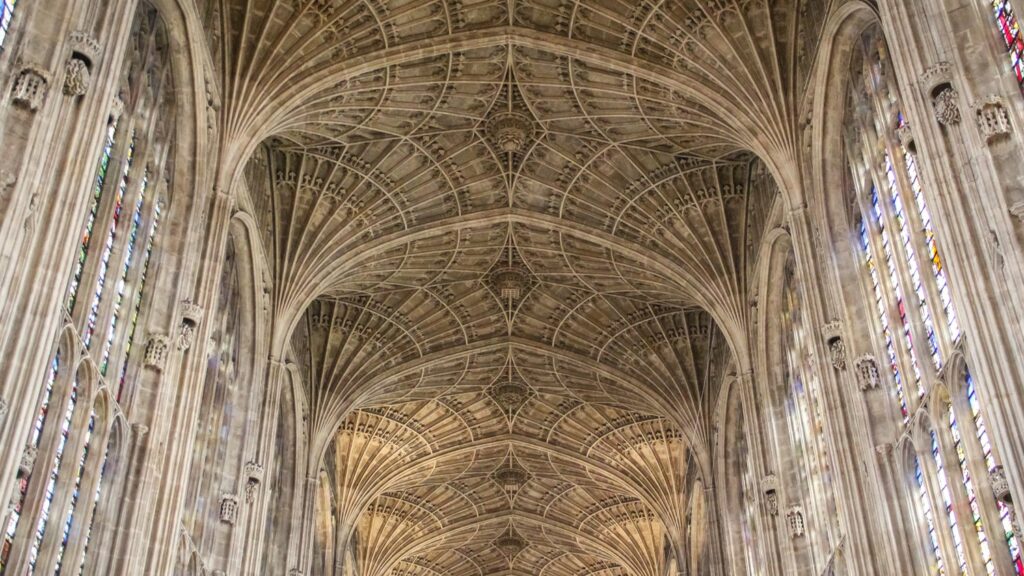

Stone architecture stands the test of time. Built around the world, these structures have been constructed for thousands of years. With diverse applications and uses, stone is chosen for its durability, performance and aesthetic qualities. Providing different varieties like limestone and granite to travertine and marble, ABC Stone is a company with rare and hard-to-find stones from quarries worldwide. By diversifying their material portfolio and service offerings, they’ve quickly become a one-stop resource for the architecture and design community.

Chosen to meet contextual and functional requirements, stone buildings give way to a vast array of different formal expressions. Whether cut or carved away, stone is used in architecture for everything from flooring to walls. The following projects showcase some of ABC Stone‘s collaborations with designers. From locations in New York City and Hicksville, ABC helps architects and teams find the right products for their specific projects. From residential to public and cultural work, the following designs showcase the versatility and potential of stone architecture.

Tata Innovation Center at Cornell Tech

By WEISS/MANFREDI Architecture/Landscape/Urbanism, New York, NY, United States

Outside the Tata Innovation Center and the surrounding grounds on Roosevelt Island, ABC provided a series of granite stone pavers. The project itself was developed by Forest City New York to supports Cornell Tech’s efforts to fuse entrepreneurial and academic ambitions on its new Roosevelt Island campus in New York City. One-third of the 235,000-square-foot building hosts Cornell Tech studios, labs, classrooms, and event spaces, while the upper levels are dedicated to a mix of technology-focused companies and start-ups.

Outside the Tata Innovation Center and the surrounding grounds on Roosevelt Island, ABC provided a series of granite stone pavers. The project itself was developed by Forest City New York to supports Cornell Tech’s efforts to fuse entrepreneurial and academic ambitions on its new Roosevelt Island campus in New York City. One-third of the 235,000-square-foot building hosts Cornell Tech studios, labs, classrooms, and event spaces, while the upper levels are dedicated to a mix of technology-focused companies and start-ups.

All of the occupants share central, light-filled circulation spaces with panoramic skyline views and lounges that encourage social interaction and collaboration. The building’s cantilevered southwest and northeast wings shelter outdoor social spaces that animate the ground floor retail spaces and entry terrace. Anticipating environmental challenges such as rising sea levels and increased flood risk, the Tata Innovation Center is designed for maximum resilience with an entry floor that rises seven feet above the 100-year flood plain.

The Barnes Foundation

By Tod Williams Billie Tsien Architects | Partners, Philadelphia, PA, United States

The Barnes Foundation collection was relocated to a 93,000 square foot, LEED Platinum building on the Benjamin Franklin Parkway in downtown Philadelphia. Conceived as “a gallery in a garden and a garden in a gallery,” the new building honors the past Merion facility and provides visitors with a personal experience. Clad in fossilized limestone and crowned by a luminous light box, the two-story building, with an additional level below grade, is set in a public garden.

The Barnes Foundation collection was relocated to a 93,000 square foot, LEED Platinum building on the Benjamin Franklin Parkway in downtown Philadelphia. Conceived as “a gallery in a garden and a garden in a gallery,” the new building honors the past Merion facility and provides visitors with a personal experience. Clad in fossilized limestone and crowned by a luminous light box, the two-story building, with an additional level below grade, is set in a public garden.

The tripartite building plan consists of the gallery housing the collection, the L-shaped support building, and a court between the two. The L-shaped building provides facilities for the foundation’s core programs in art education, as well as for conservation, temporary exhibitions, and visitor amenities. The façade of the massive building is dressed in Ramon Grey limestone — quarried in the Negev desert and supplied by ABC Stone. In total, 4,000 stone panels were employed to construct the facility.

Field House

By Stelle Lomont Rouhani Architects, Sagaponack, New York

Field House was built between ocean and pond. With the landscape seemingly running through it, the house was designed around flooding and wind. It was constructed on piles with a steel frame and high density limestone. The house is approached through a terraced set of stairs, and the interior palette matches the exterior, with the limestone extending throughout the main level and reappearing as solid blocks in bathrooms.

Field House was built between ocean and pond. With the landscape seemingly running through it, the house was designed around flooding and wind. It was constructed on piles with a steel frame and high density limestone. The house is approached through a terraced set of stairs, and the interior palette matches the exterior, with the limestone extending throughout the main level and reappearing as solid blocks in bathrooms.

The intention throughout is to reinforce rather than detract from the natural beauty of the surroundings. Valders Limestone from Wisconsin used inside and out. The stone is used landscape elements such as the pool and spa and the surrounding terraces. It continues through the inside main level of the house reinforcing the indoor outdoor relationship.

Pierhouse and 1 Hotel Brooklyn Bridge

By Marvel, and INC Architecture & Design, Brooklyn, NY, United States

1 Hotel overlooks the East River in Brooklyn’s DUMBO neighborhood and features more than 10,000 square feet ABC’s Montclair Danby Vein Cut, Mountain White Danby, and Crystal Grey Danby. The Pierhouse and 1 Hotel Brooklyn Bridge building echoes the park’s simplified use of stone and steel. It steps down to meet the green lawns with planted roofs. Using stone from a Vermont quarry helped the project achieve the designation of LEED Gold certification.

1 Hotel overlooks the East River in Brooklyn’s DUMBO neighborhood and features more than 10,000 square feet ABC’s Montclair Danby Vein Cut, Mountain White Danby, and Crystal Grey Danby. The Pierhouse and 1 Hotel Brooklyn Bridge building echoes the park’s simplified use of stone and steel. It steps down to meet the green lawns with planted roofs. Using stone from a Vermont quarry helped the project achieve the designation of LEED Gold certification.

The Pierhouse and 1 Hotel Brooklyn Bridge development includes a 194-room hotel and 106-unit condo residence in Brooklyn Heights. The design allows for unparalleled views of the New York harbor and the park. The building was made to serve as an improved link between Furman Street and the park open space.

Perry World House

By Tod Williams Billie Tsien Architects | Partners, Philadelphia, PA, United States

For the Perry World House, the University of Pennsylvania needed a space for its new institute that would aggregate all its international activities. This became a renovated cottage that was originally built in 1851. Designed by 1100 Architect, the team preserved the house while transforming the site into a 21st century flagship for this newly formed institute. ABC Worldwide Stone was responsible for sourcing, selecting, quality checks, logistics and fabrication approvals on all the project’s 1,850 cubic feet of Renaissance Beige limestone.

For the Perry World House, the University of Pennsylvania needed a space for its new institute that would aggregate all its international activities. This became a renovated cottage that was originally built in 1851. Designed by 1100 Architect, the team preserved the house while transforming the site into a 21st century flagship for this newly formed institute. ABC Worldwide Stone was responsible for sourcing, selecting, quality checks, logistics and fabrication approvals on all the project’s 1,850 cubic feet of Renaissance Beige limestone.

The new limestone-clad building sits at the heart of Penn’s campus, mediating two very different conditions: a pedestrian/domestic scale to its south and west, and a busy urban scale and traffic corridor to its north and east. The building’s facets allow it to modulate its scale in a seamless way, deferring to the original house, on one hand, but providing a strong edge to the busy street, on the other.

Clinton Hill Brownstone

By Michael K Chen Architecture, Clinton Hill, New York

MKCA’s gut renovation and exterior restoration of a landmark Brooklyn brownstone balances history with a playful intervention. Located in the historic Clinton Hill neighborhood, the original structure was abandoned to decay for twenty years. The design of the house balances stabilizing the building and recapturing its original details with efforts to create a new home in an adventurous, innovative manner, producing an appealing aesthetic between the historic elements and the new additions.

MKCA’s gut renovation and exterior restoration of a landmark Brooklyn brownstone balances history with a playful intervention. Located in the historic Clinton Hill neighborhood, the original structure was abandoned to decay for twenty years. The design of the house balances stabilizing the building and recapturing its original details with efforts to create a new home in an adventurous, innovative manner, producing an appealing aesthetic between the historic elements and the new additions.

For the project, color is an important component of the design, and it is treated in a three-dimensional, spatial manner. ABC Stone was used throughout the project interiors. Across the redesign, a rigorously uniform yet distinct palette washes over each room, retaining the boldness and vibrancy of the original hues, while rendering the spaces more modern, cohesive and calm.

Architizer’s A+Product Awards has officially launched! Get your products in front of the AEC industry’s most renowned designers by submitting today.

In the webinar, Ryan thoroughly explored the ins and outs of wall protection — from materials and installations to key decision-making processes, highlighting the main challenges architects often face.

In the webinar, Ryan thoroughly explored the ins and outs of wall protection — from materials and installations to key decision-making processes, highlighting the main challenges architects often face. The presentation offers deep insights, real-world examples and straightforward guidance, making it a must-watch for every architect and builder. Dive in to strengthen your designs and focus on lasting interiors.

The presentation offers deep insights, real-world examples and straightforward guidance, making it a must-watch for every architect and builder. Dive in to strengthen your designs and focus on lasting interiors.