Electronic yarn woven into sportswear measures exhaustion levels

Spotted: According to a survey conducted by the European Commission, 38 per cent of people exercise or play sport once a week. Of course, exercise is great for physical and mental wellbeing, but pushing ourselves too far during a workout is easy, and this over-exertion can make people more prone to injury.

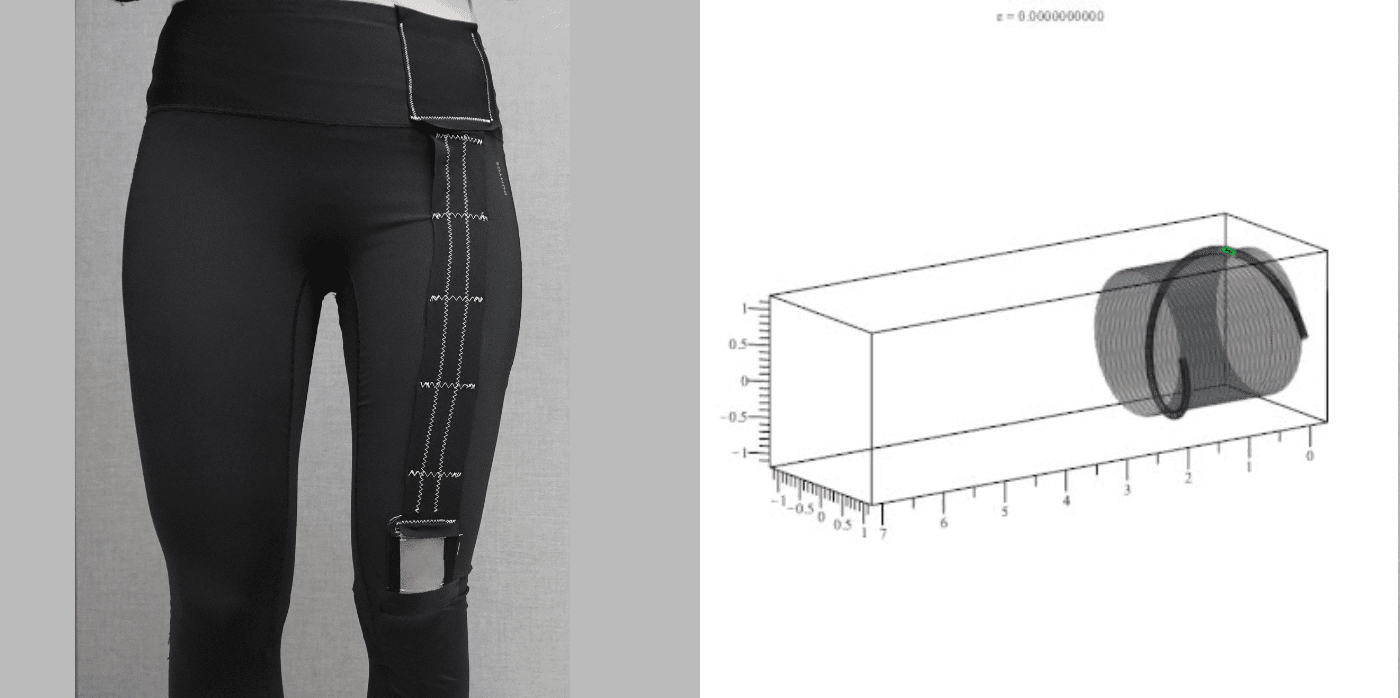

This is why researchers at ETH Zurich have developed an electronic yarn that can carefully measure how a person’s body moves. The textile sensor, which is integrated directly into close-fitting sportswear or work clothing, can predict and detect the wearer’s exhaustion levels.

The new sensor reveals when you have reached your physical limits during exercise and when you should take a break by simply glancing at your smartphone. Sensors and electronics can be integrated into clothing thanks to the yarn’s structure, in which the inner fibre is made of conductive, elastic rubber. “These two fibres act as electrodes and create an electric field. Together, they form a capacitor that can hold an electric charge,” says Tyler Cuthbert, a central figure in the research and development of the invention.

Because this stretchable sensor can be woven into the material fibres of flexible and close-fitting clothing, large-scale production is easier and cheaper. And because the sensor is worn so close to the body, it’s possible to capture bodily movements extremely precisely.

Right now, the researchers are working on turning their prototype into a market-ready product.

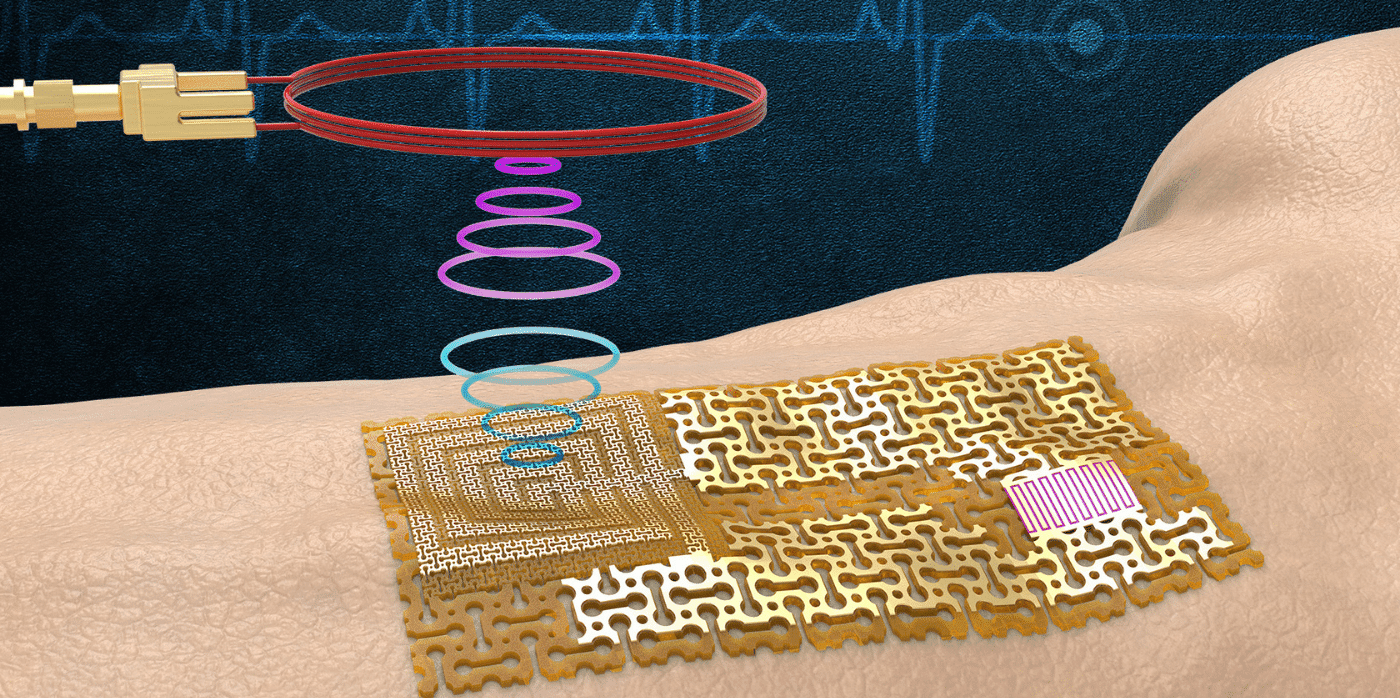

Springwise has previously spotted other smart clothing innovations, including one that monitors the wearer’s heartbeat and another that measures a customer’s precise body shape to avoid online clothes returns.

Written By: Georgia King