Could we make milk from CO2?

Spotted: Over 80 per cent of the global population regularly consumes milk and other dairy products, with approximately 37 million metric tonnes of fresh dairy produce being consumed around the European Union each year. All of this consumption has an impact on the planet, with cattle – including dairy cows – responsible for 65 per cent of the world’s total livestock-related greenhouse gas emissions. Due to concerns over these negative environmental impacts, it’s possible that production of milk in the EU will be dropping 0.2 per cent a year by 2032.

To avoid the emissions and related land-use changes and soil degradation currently caused by the dairy industry, a new project is looking for inspiration from the air. Finnish startup Solar Foods has developed a proprietary microbe that feeds on hydrogen and carbon dioxide from the air to create a high-protein ingredient, Solein, which has already been approved for sale in Singapore.

Springwise first spotted Solar Foods back in 2019, but since then the company has made great strides. In September 2023, it was revealed that Solar Foods will lead a consortium including the University of Groningen, RWTH Aachen University, and FGen AG, that will explore the use of the same technology for the production of milk.

Backed by €5.5 million worth of funding from the European Innovation Council, the ‘HYDROCOW’ project aims to create a microbe that, using water and electricity, can convert carbon dioxide and hydrogen into beta-lactoglobulin – a whey protein that is a main component of dairy milk.

Combining expertise from all participants in the project, including FGen’s superior screening process and the University of Groningen’s genetic modification techniques, the project will design, test, and modify the best protein-secreting microbe to create milk. If successful the techniques and technologies could be used to create a huge variety of animal-free proteins in future, for food and pharmaceutical applications.

Back in May this year, Solar Foods also partnered with Japanese company the Ajinomoto Group to test the marketability of Solein products from the beginning of 2024.

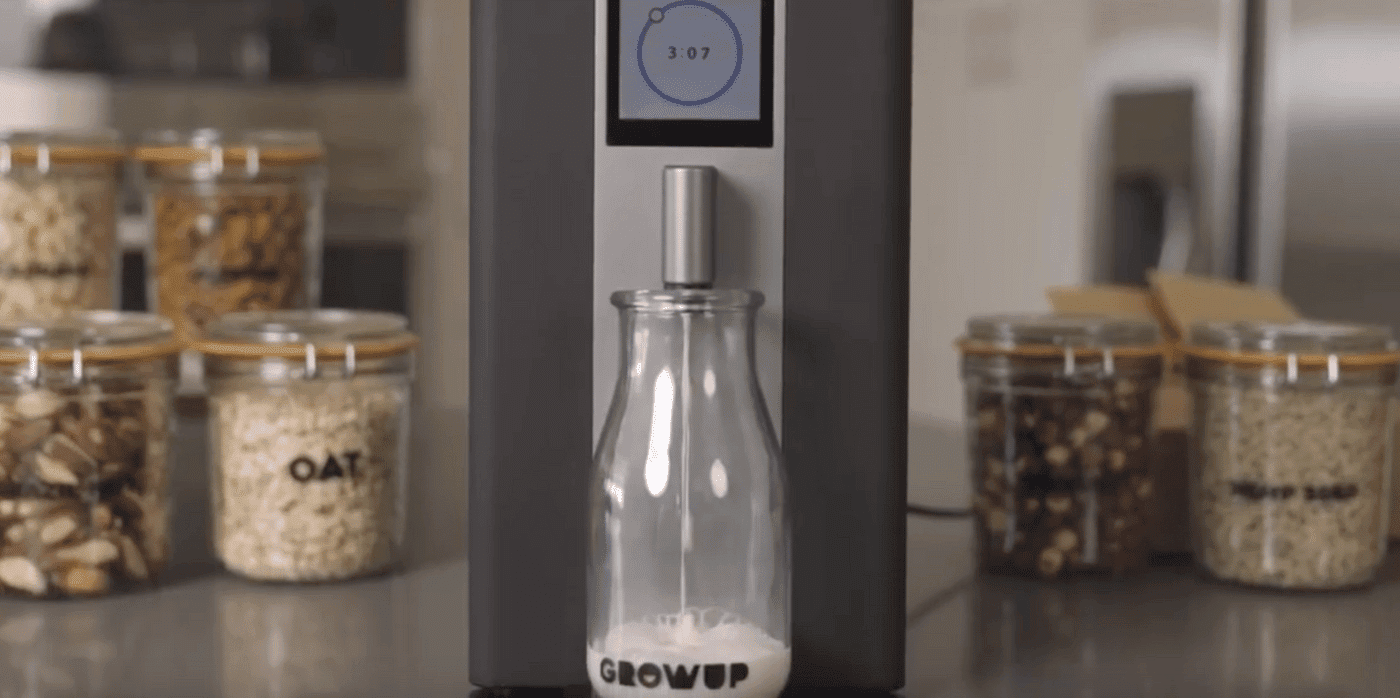

Springwise has spotted other innovators looking to change up typical milk production, including by using no cows in India and a countertop plant milk brewer for home use.

Written By: Matilda Cox