MIT engineers create battery alternative using cement and carbon black

Scientists at the Massachusetts Institute of Technology have developed a low-cost energy storage system that could be integrated into roads and building foundations to facilitate the renewable energy transition.

The research team has created a supercapacitor – a device that works like a rechargeable battery – using cement, water and carbon black, a fine black powder primarily formed of pure carbon.

The breakthrough could pave the way for energy storage to be embedded into concrete, creating the potential for roads and buildings that charge electric devices.

Unlike batteries, which rely on materials in limited supply such as lithium, the technology could be produced cheaply using materials that are readily available, according to the researchers.

They describe cement and carbon black as “two of humanity’s most ubiquitous materials”.

“You have the most-used manmade material in the world, cement, combined with carbon black, which is a well-known historical material – the Dead Sea Scrolls were written with it,” said MIT professor Admir Masic.

The research team included Masic and fellow MIT professors Franz-Josef Ulm and Yang-Shao Horn, with postdoctoral researchers Nicolas Chanut, Damian Stefaniuk and Yunguang Zhu at MIT and James Weaver at Harvard’s Wyss Institute.

“Huge need for big energy storage”

They believe the technology could accelerate a global shift to renewable energy.

Solar, wind and tidal power are all produced at variable times, which often don’t correspond with peak electricity demand. Large-scale energy storage is necessary to take advantage of these sources but is too expensive to realise using traditional batteries.

“There is a huge need for big energy storage,” said Ulm. “That’s where our technology is extremely promising because cement is ubiquitous.”

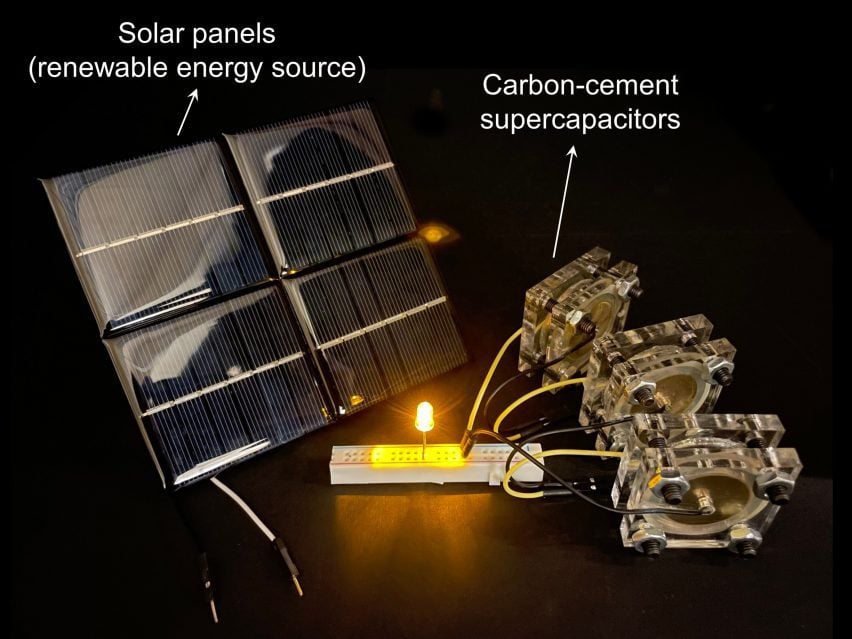

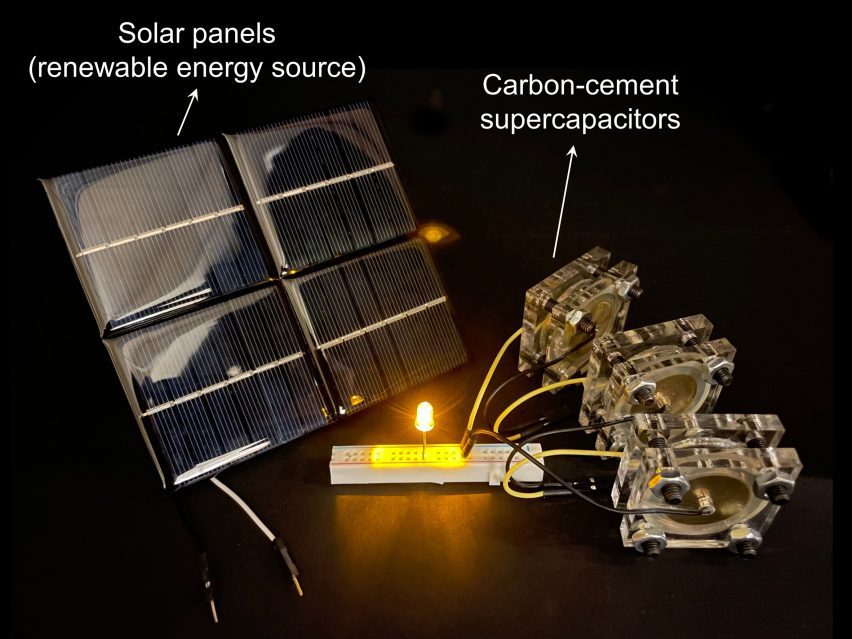

The team proved the concept works by creating a set of button-sized supercapacitors, equivalent to one-volt batteries, which were used to power an LED light.

They are now developing a 45-cubic-metre version to show the technology can be scaled up.

Calculations suggest a supercapacitor of this size could store around 10 kilowatt-hours of energy, which would be enough to meet the daily electricity usage of a typical household.

This means that a supercapacitor could potentially be incorporated into the concrete foundation of a house for little to no additional cost.

“You can go from one-millimetre-thick electrodes to one-metre-thick electrodes, and by doing so basically you can scale the energy storage capacity from lighting an LED for a few seconds to powering a whole house,” Ulm said.

The researchers suggest that embedding the technology into a concrete road could make it possible to charge electric cars while they are travelling across it, using similar technology to that used in wireless phone chargers.

Battery-powered versions of this system are already being trialled across Europe.

Carbon black key to “fascinating” composite

Supercapacitors work by storing electrical energy between two electrically conductive plates. They are able to deliver charge much more rapidly than batteries but most do not offer as much energy storage.

The amount of energy they are able to store depends on the total surface area of the two plates, which are separated by a thin insulation layer.

The version developed here has an extremely high internal surface area, which greatly improves its effectiveness. This is due to the chemical makeup of the material formed when carbon black is introduced to a concrete mixture and left to cure.

“The material is fascinating,” said Masic. “The carbon black is self-assembling into a connected conductive wire.”

According to Masic, the amount of carbon black needed is very small – as little as three per cent.

The more is added, the greater the storage capacity of the supercapacitor. But this also reduces the structural strength of the concrete, which could be a problem in load-bearing applications.

The “sweet spot” is believed to be around 10 per cent.

The composite material could also be utilised within a heating system, the team suggested. Full details of their findings are due to be published in an upcoming edition of science journal PNAS.

Other attempts at creating large-scale, low-cost energy storage systems include Polar Night Energy’s “sand battery”, which is already servicing around 10,000 people in the Finnish town of Kankaanpää.

The top image is courtesy of Shutterstock.