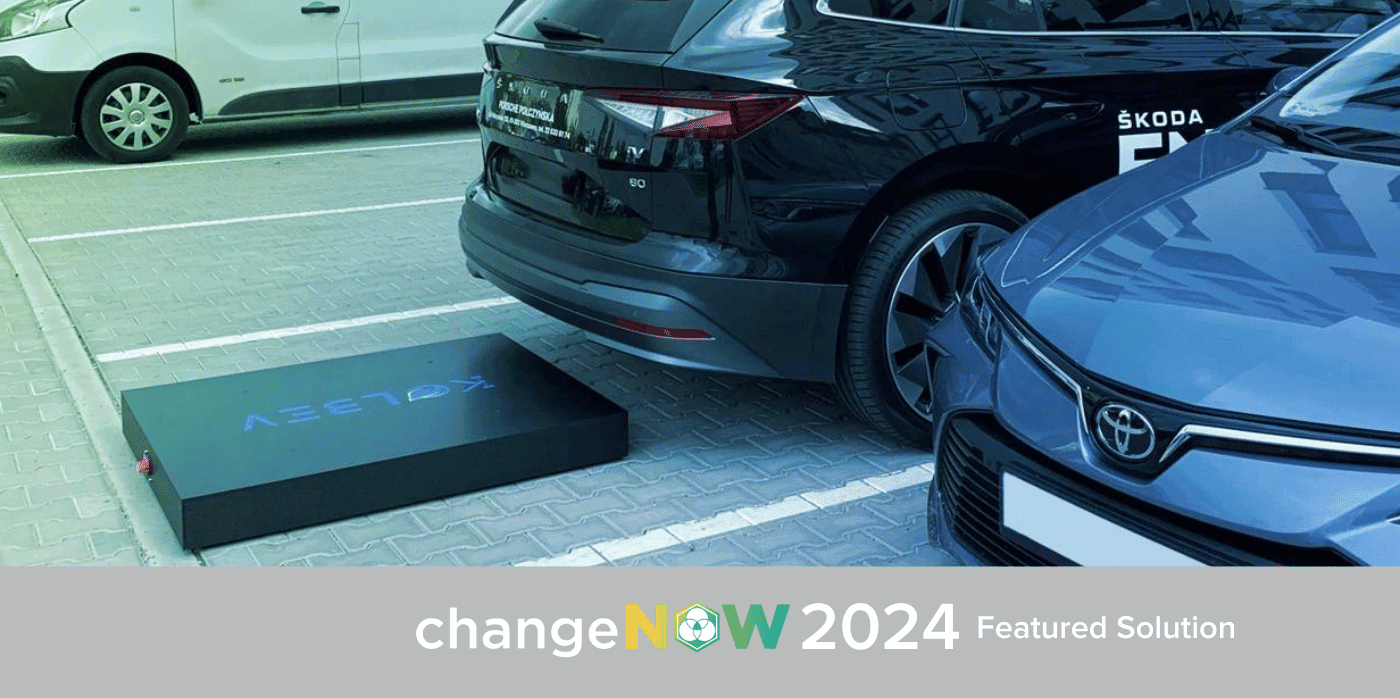

Robotic, on-demand tech for seamless EV charging

Spotted: According to a McKinsey survey, the availability of chargers is the most significant consideration of sceptical EV buyers. Hoping to tackle that is Kolbev, a Swiss-based company, which envisions a future where renewable energy seamlessly integrates into urban landscapes. The company’s innovation: an on-demand, wireless EV charging system equipped with energy storage, designed to be swiftly deployed to city locations.

Subscribing customers can use Kolbev’s app to request e-charging in specific car parks and city hotspots. The robotic charger will then autonomously locate the e-car and manoeuvre beneath the vehicle to initiate charging, offering a space-saving solution in compact city areas.

Importantly, Kolbev’s innovation removes the barrier of costly upfront investments by operating without the need for infrastructure. This approach not only ensures easy implementation but opens up the possibility for rapid scalability. Additionally, Kolbev’s solution delivers renewable energy, aiming to catalyse the widespread adoption of EVs in a more sustainable manner.

Springwise has previously spotted other innovations aimed at improving the way EVs are charged, from a new charging system that improves reliability, scalability, and cost-effectiveness to an AI-powered smart charging technology.

Written By: Georgia King