This article was written by Burgess Brown. Healthy Materials Lab is a design research lab at Parsons School of Design with a mission to place health at the center of every design decision. HML is changing the future of the built environment by creating resources for designers, architects, teachers, and students to make healthier places for all people to live. Check out their podcast, Trace Material.

We’ve got good news and bad news. Let’s start with the bad. We are dealing with a well-documented plastics problem that is choking our planet and infecting our bodies. This is not news. But, there is new evidence of an under-reported key player in our plastics crisis: paint.

Thanks to tireless advocacy work over the last decade, many of us are familiar with the concept of volatile organic compounds (VOCs) in paints and the threat they pose to our bodies and the planet. We are now spoilt for choice when it comes to low and no-VOC paint options, even at big box stores. This is progress, no doubt, but VOCs are only one of the dangers of paint, and it’s vital that we once again reconsider how we make and use paint.

Environmentalists filter the microplastic waste contaminated with the seaside sand.

The vast majority of paints currently used in our homes, offices, and schools across the country (where we spend 90% of our time) are acrylic based —sometimes called “acrylic latex.” These paints are popular for a good reason. They are affordable, they dry quickly, and once dry, are water resistant. These characteristics are achieved because, at its core, acrylic latex paint is pigment suspended in liquid plastic. The plastic binders and additives found in acrylic latex paint are often toxic to humans and our environment. Some concerning additives are alkylphenol ethoxylates (APEs)— a group of chemicals combined in acrylic paint for viscosity that are suspected endocrine disruptors, leading to hormonal dysfunction in humans and animals, and the disruption of marine life. Our widespread use of acrylic latex paint has created interior environments wrapped in toxic plastic bubbles.

Remember, good news is coming (spoiler: there are alternatives to plastic paint)… but first a bit more of the bad. Beyond the immediate threats to the health of building occupants, plastic paints, which never biodegrade, pose a host of dangers to humans, animals, sealife and the environment once their useful life is over. A recent study released by Environmental Action, a Swiss-based scientific research firm of world-renowned experts on plastic pollution, has revealed that our understanding of paint’s role in plastic pollution was dramatically underestimated.

The study finds that paint is the leading source of microplastics in our oceans and waterways.

12th Century Lime Paint Detail, Church in Store Heddinge, Denmark, 2018. Photo by J.Ruth

According to Environmental Action, an astounding 58% of microplastics in oceans and waterways began their life as paint. While some of this paint comes from sectors like the automotive industry or road markings, the largest single contribution comes from the architecture sector, which makes up 48% of pollution. Plastic particles have contaminated the entire planet and are wreaking havoc on ecosystems. New research has revealed a plastic-induced illness in seabirds dubbed ‘plasticosis,’ and microplastics were detected in the blood of 80% of participants in a recent study. The issue is acute, the need to replace petroleum-based paints is urgent, and the architecture industry must take action.

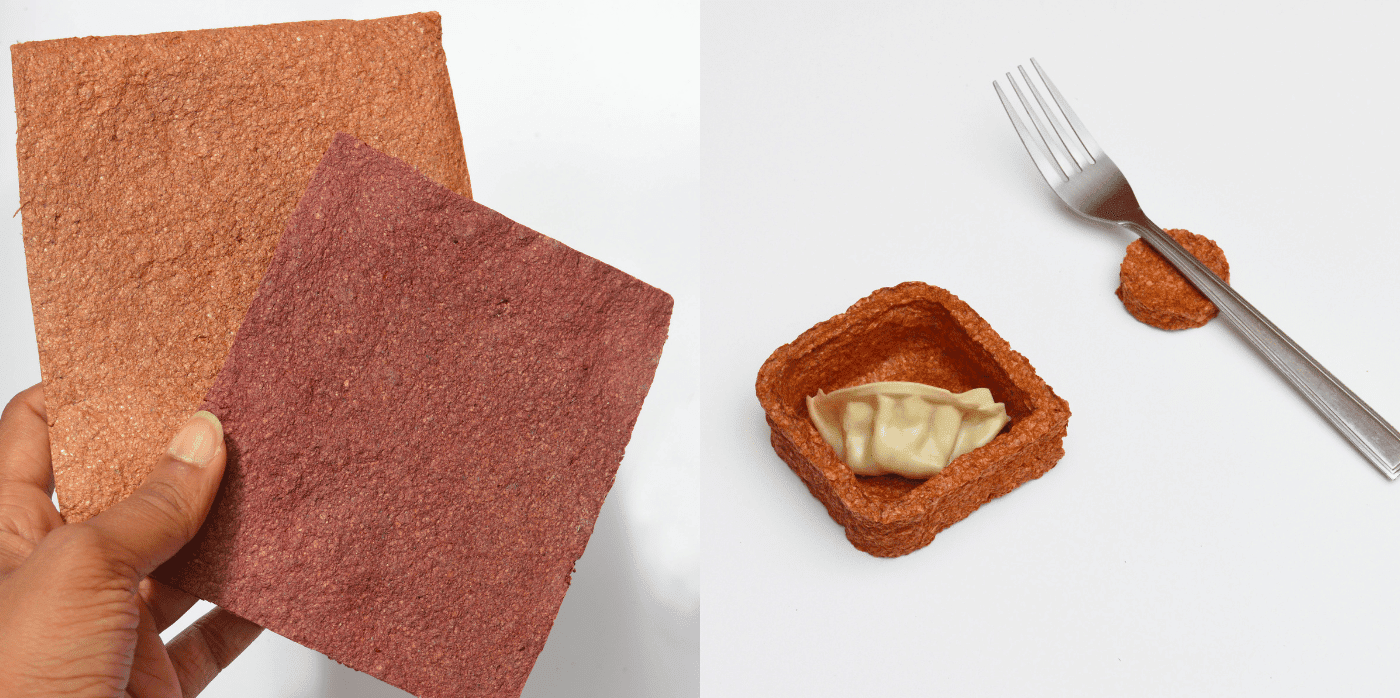

We promised some good news and here it is: healthier paint alternatives exist, and have for centuries! Mineral, clay, and plant-based paints are now readily available. Although transitioning to these paints sometimes requires slightly different installation and practices, it’s an easy learning curve. These paints can be used in interior and exterior applications and can be a superior option to minimize mold, without the addition of problematic additives. Unlike acrylic paints that lightly coat a wall surface, mineral paints penetrate into porous surfaces, which means they will be significantly more durable. Mineral paints, like lime paints for example, have a long history that weave through diverse cultures. Minerals are abundant — limestone makes up 10% of the earth’s crust — and modern technology has made mineral paints more durable than ever.

Lime Paint Color Swatches at KALK in Denmark, 2018. Photo by J.Ruth

In our research at Healthy Materials Lab, we have rigorously investigated and installed some of these plastic paint alternatives that are part of our meticulously vetted materials collection. These products not only avoid VOCs and other hazardous additives, they help to make healthier interiors by absorbing impurities from the air, actively improving indoor air quality.

Romabio employs an ancient recipe based on lime and offers both interior and exterior paints. The exterior paint is known for its superior coverage on brick, stucco and other porous surfaces. Some water is added to the lime pigment in the bucket before painting, reducing the weight of the paint during transportation. We painted our offices over five years ago and even after scrubbing scuff marks, it still looks fantastic.

Keim Paints, made from potassium silicate minerals, another abundant mineral class, offer a low-embodied carbon option that is free of plasticizers or preservatives. Just one coat of primer and one coat of paint provides enough coverage and is high-performing on a range of surfaces. Reducing the number of paint coats reduces the upfront costs, making it an affordable option. Beyond their health benefits, mineral paints are beautiful! They interact with light in a totally different way than synthetics, refracting it across spaces and creating warmth and brightness.

Lime-Painted Ceiling by Salty Labs, Pedagogy ike Shop NYC, 2022. Photo by Annie Schlecter

Real Milk Paint Co. offers a paint made from, you guessed it, milk (protein) along with lime, clay and earth pigments. It comes as a powder to be mixed with water in desired quantity. Less water creates an opaque coating and more water creates a transparent coating.

It’s important to note that, when it comes to healthier materials, labels can be deceiving. Some acrylic paints may contain trace amounts of minerals and be marketed as “mineral paints.” By the same token, some “mineral paints” can contain trace amounts of plastic polymers. Full ingredient transparency is a cornerstone of material health, as is practical patience when it comes to the transition away from petroleum based products. It may not always be possible to avoid acrylic paint altogether, but we have the option to dramatically reduce our consumption. In our materials collection, you’ll find some ‘less harmful’ plastic paint—although we strongly recommend avoiding them. Acrylic latex paint is often the first choice in many projects and low or zero VOC options are available. We acknowledge that this is a good first step to take.

Whenever possible, we encourage a consideration of the entire lifecycle of paint. According to the Environmental Action study, 33% of the total paint used in the Architectural sector will eventually end up in the environment. If that paint is made of plastic, it will end up clogging our waterways, infecting animals, and appearing in our bodies. If we opt for healthier alternatives, the paint will return to the earth as it came. That is better for all of us.

Judging for the 11th A+Awards is now underway! While awaiting the Winners, learn more about Architizer’s Vision Awards. The Early Entry Deadline on May 5th is fast approaching. Start your entry today >