Can coal be converted into sustainable protein?

Spotted: It’s well-established that the food we eat has a huge impact on the planet, with food production generating over a quarter of global greenhouse gas emissions. But, do you ever consider the impact of what we feed our livestock? For instance, feed production accounts for between 50 and 85 per cent of the climate change impact of pigs and poultry. And often, countries must rely on imports for quality feed, including China, which has been heavily dependent on imported soy – raising concerns over supply and food security in the country.

Now, however, researchers at the Tianjin Institute of Industrial Biotechnology at the Chinese Academy of Sciences believe they have a more sustainable and affordable alternative protein source: coal.

The team, led by Professor Wu Xin, converted coal into methanol via coal gasification, and this methanol was then fermented using a type of yeast called Pichia Pastoris to create single-cell proteins. This particular yeast strain is optimised for growth in methanol, achieving a methanol-to-protein conversion rate of 92 per cent the theoretical value. According to Professor Wu Xin, this makes the novel process far more efficient at producing crude protein than any other process in the food chain at the moment.

The proteins produced contain a holistic profile of amino acids, vitamins, and minerals, which makes the resource a viable substitute for foodstuffs like fishmeal, soybeans, meat, and skimmed milk powder. For the future, the team aims to continue refining the process and use of methanol to make protein, hoping to make it even cheaper and more efficient.

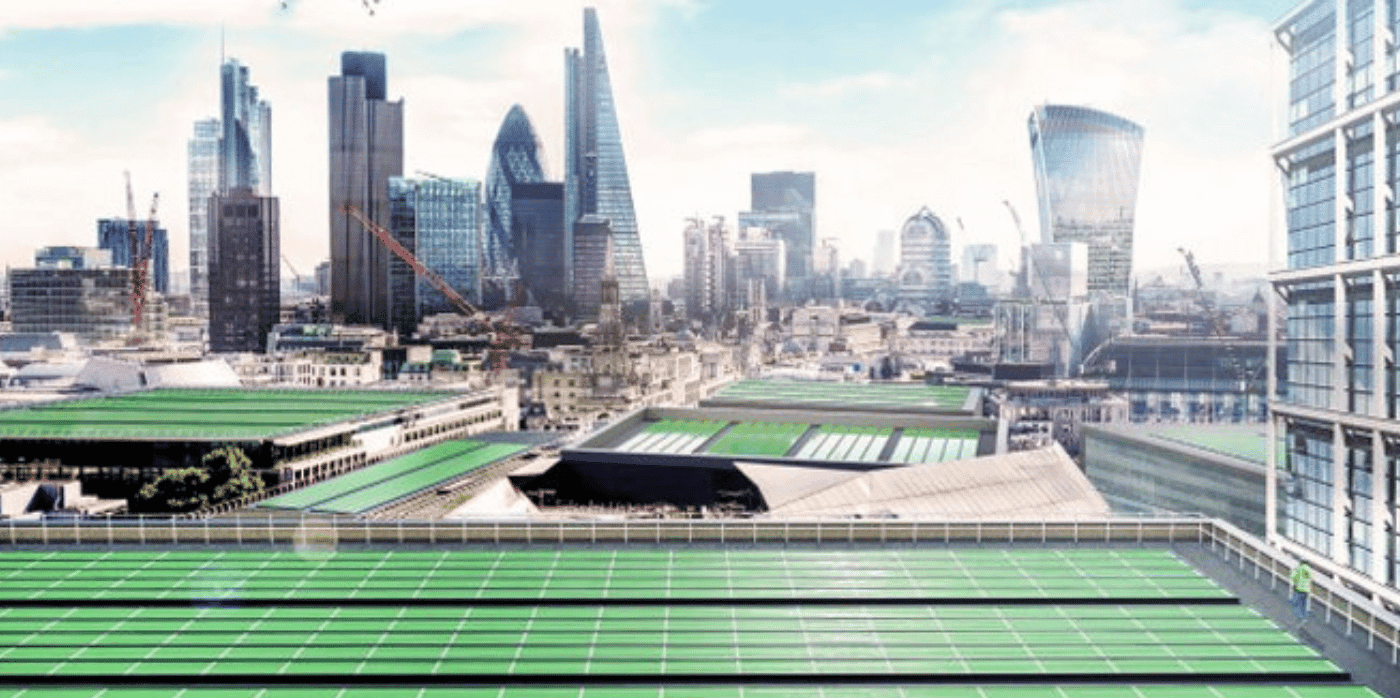

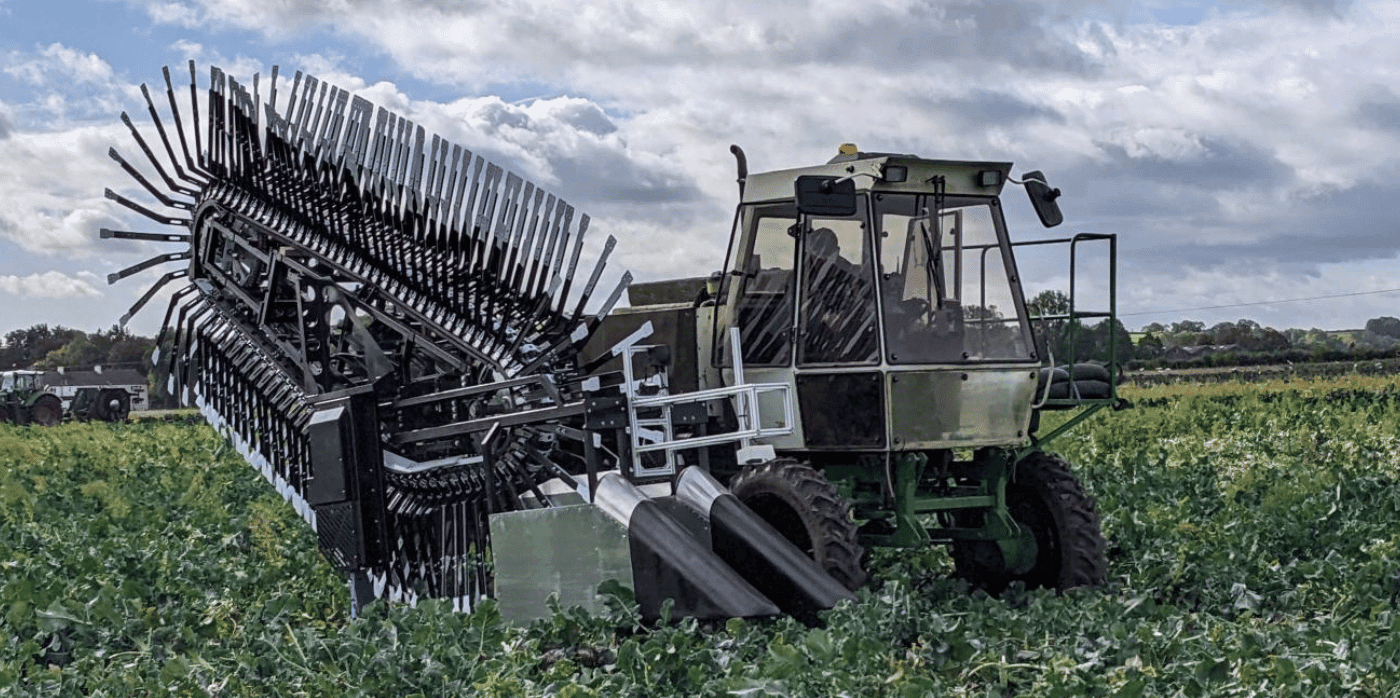

There’s a lot of room for improvement in the global food system, and luckily innovators are rising to the challenge. Springwise has also spotted this AI-driven approach to making tastier alternatives to meat as well as these compact urban farms that tackle food insecurity.

Written By: Archie Cox