A backpack made from recycled plastic and captured carbon

Spotted: Stand.earth’s 2022 review of the fashion industry’s global carbon emissions found an alarming increase. Of the 10 major brands that were assessed, all were committed to the United Nations Fashion Industry Charter for Climate Action, yet only one company is on track to reduce supply chain emissions enough to keep global warming at the 1.5 degree Celsius or below mark.

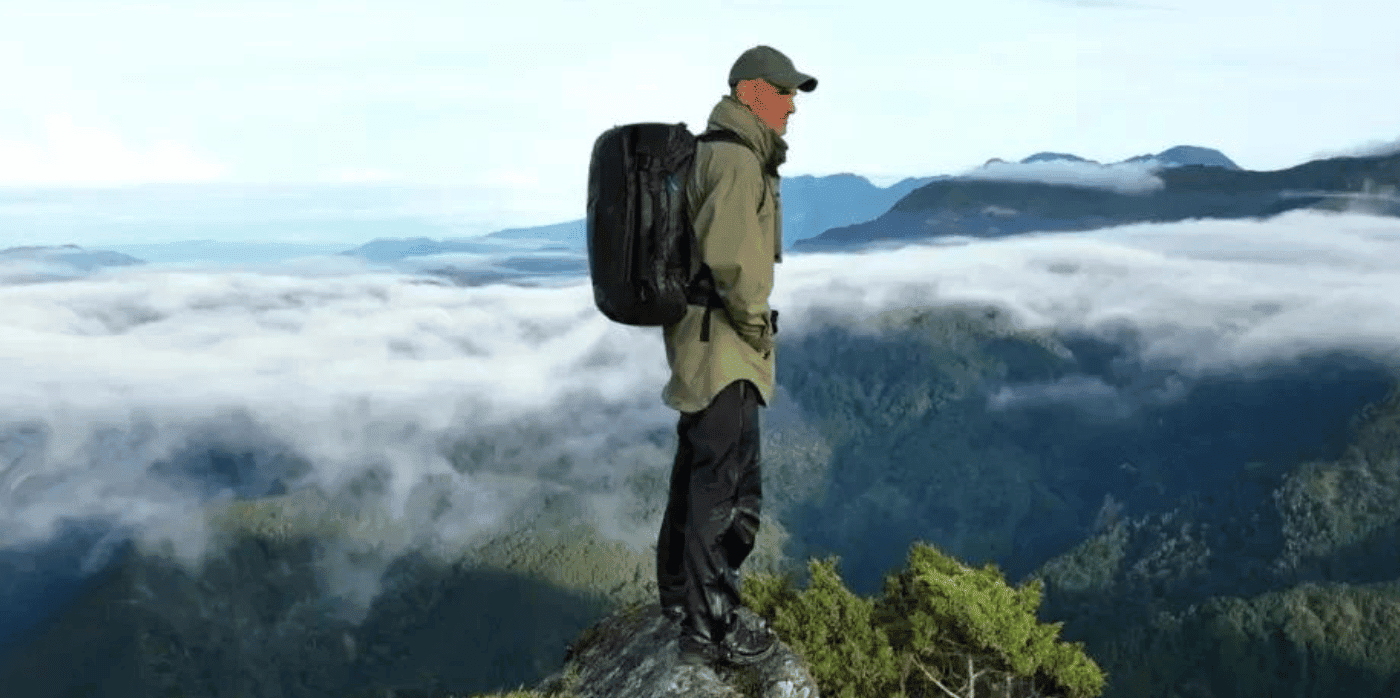

Ways to reduce emissions include working with recycled materials and designing products for longevity. Materials science company GroundTruth is doing just that for its bags and accessories. The company makes carbon-neutral, vegan, recycled plastic backpacks and carryalls that have a 10-year performance guarantee. The latest product is the 38L Hybrid Duffle Pack that incorporates the company’s latest technology – hardware made from captured carbon.

The packs can be carried by hand, on the back, and across the body, with bottle holders on the front of the pack to make hydrating easy. The bags also open a full 180 degrees for swift accessibility. Notably, each duffle uses 123 plastic bottles for the exterior fabric, and the interior fabric is made from recycled fishing nets.

In tests, the captured carbon material performed 40 per cent better than virgin plastic. The waterproof coating on the material contains no volatile organic compounds, and the company works with Bluesign-certified manufacturers that meet Global Recycled Standards for safe and healthy production processes. Explorer Ed Stafford helped design and test the functionality of the pack’s features and in May 2023, GroundTruth closed a successful Kickstarter campaign and started production of the Hybrid Duffle in Jakarta.

The complexity of the fashion industry supply chain is inspiring an equally impressive number of improvements to its ecological footprint, and Springwise has spotted the growing of cotton indoors and fabrics made from banana fibres.

Written By: Keely Khoury