On-demand data makes recycling easy

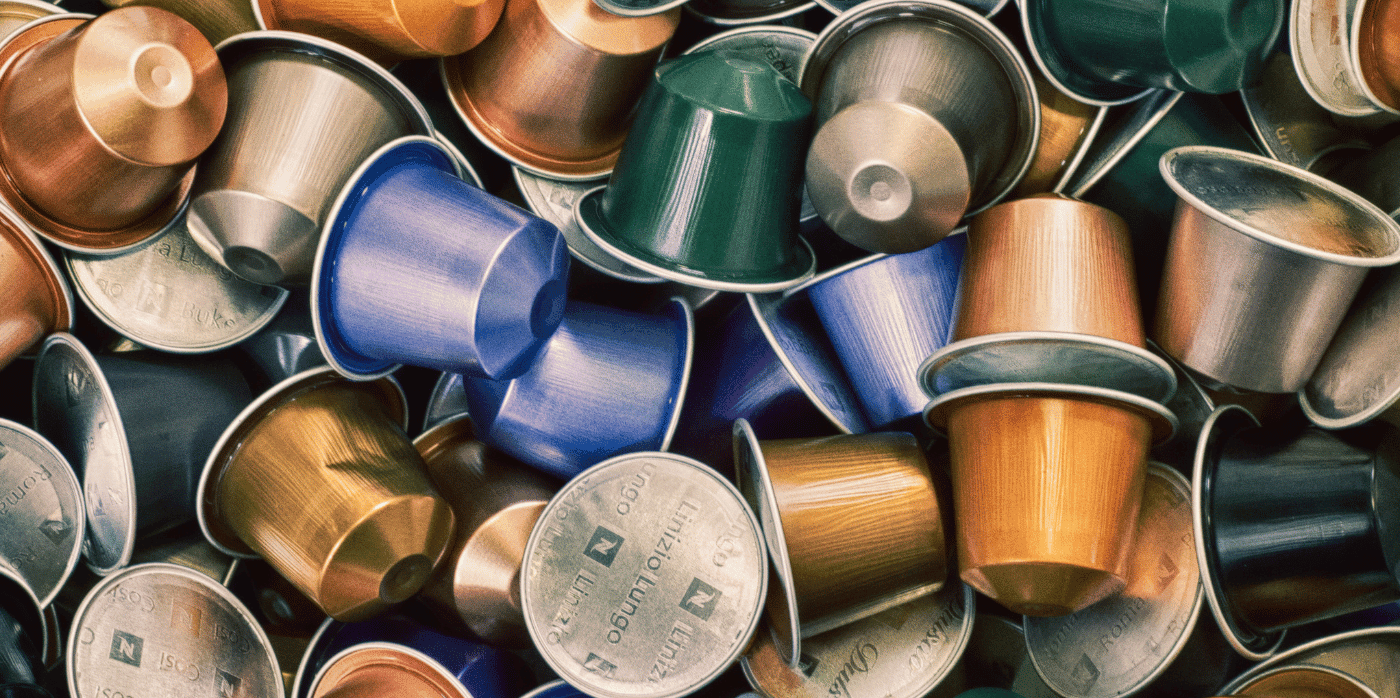

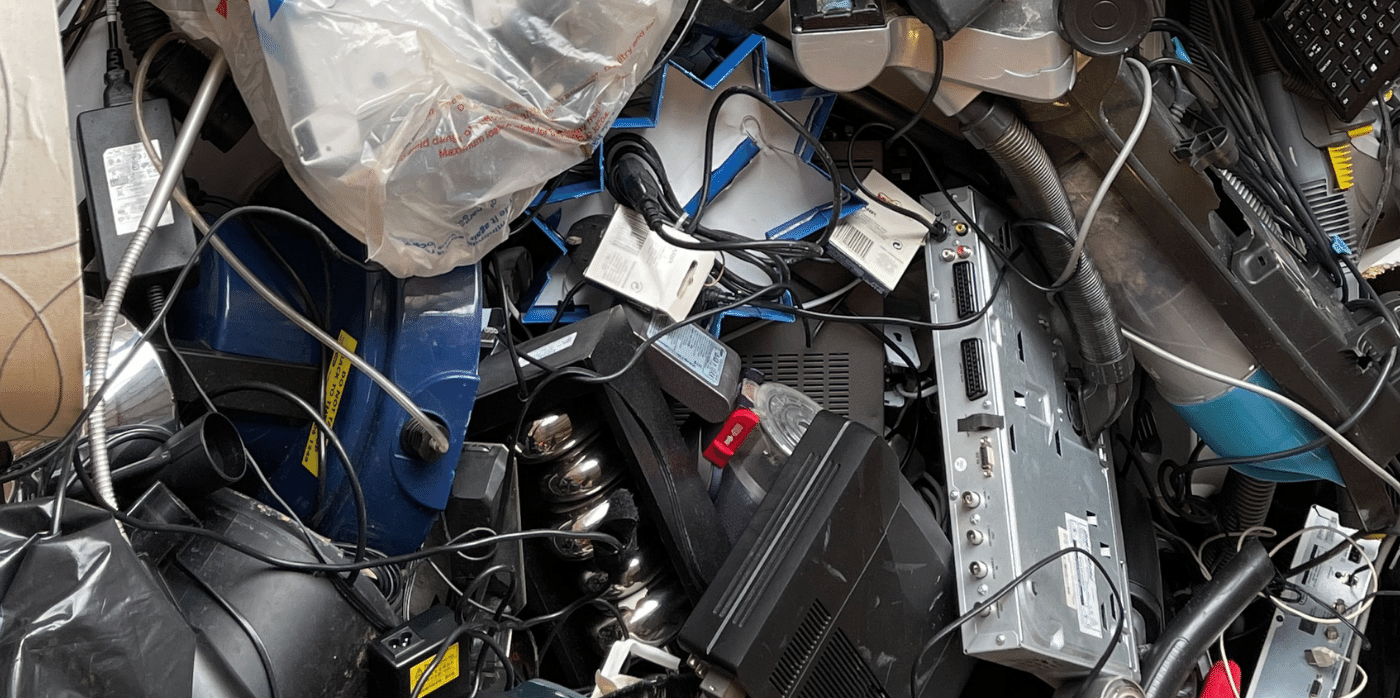

Spotted: Despite all of the interest in achieving net zero and reducing waste, recycling rates in the US actually decreased between 2018 and 2021. One of the reasons for this is that regulations vary from state to state, leaving many people confused about exactly what can and can’t be recycled. Faced with this problem, two female engineers at the University of Georgia came up with a solution – a platform that provides users with real-time and location-specific answers to the question ‘can I recycle this?’

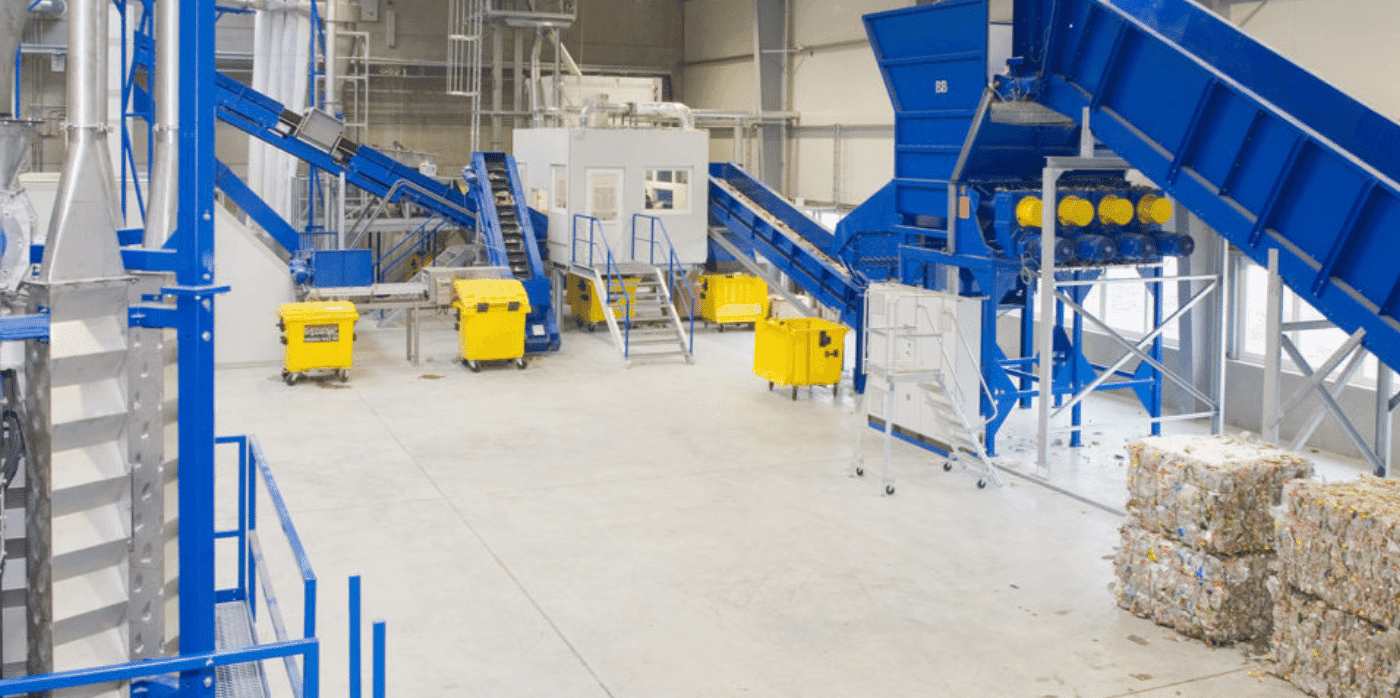

The platform, dubbed CIRT, provides customers and businesses with on-demand and location-specific data on whether materials can be recycled, composted, or must be thrown to landfill. The company remains in contact with waste management facilities to ensure the information is as accurate and up-to-date as possible.

The company provides all this information to partnering brands via an API, so that they can optimise procurement and make more sustainable choices on materials. This, in turn, enables them to track and meet ESG goals.

For customers, information is provided through an app. Brands can also add scannable CIRT QR codes to their packaging, which send customers directly to relevant information on how to dispose of the specific product where they are. And, as a further behavioural nudge, CIRT integrates recycling reminders with regular order updates.

In the archive, Springwise has spotted other innovations making recycling easier, including chemical recycling for unsorted plastics and an inclusive scheme in South Africa.

Written By: Lisa Magloff