Browse the Architizer Jobs Board and apply for architecture and design positions at some of the world’s best firms. Click here to sign up for our Jobs Newsletter.

Architecture is defined by materials and construction. In terms of building envelopes, structures, and systems, there are two primary manufacturing methods used. Additive manufacturing processes add material layer-by-layer, while subtractive manufacturing removes material to create building components or parts. Additive manufacturing, usually under the umbrella of 3D printing, is increasingly well-known, but subtractive methods have been used throughout history. In modern architecture, designers, fabricators, and manufacturers are reimagining the possibilities of subtractive manufacturing to create new forms and spaces for contemporary life.

Subtractive manufacturing is an umbrella term for different kinds of controlled machining and material removal processes. These are either performed manually or more commonly, driven by computer numerical control (CNC). Subtractive methods can start with solid blocks or material forms made from metals, plastics, wood, or other materials that are shaped through boring, cutting, drilling, and grinding. This machining process spans from CNC methods to electrical discharge machining in hard metals, as well as laser cutting (for thermoplastics, wood, acrylic, fabrics, metals) and water jet cutting for plastics, hard and soft metals, stone, glass and composites.

A two-part mold tool from MDF being machined with a 1/16″ flat end mill. Courtesy Portland CNC

The key advantage to subtractive manufacturing is that it’s ideal for tight tolerances and geometries that are difficult to mold, cast, or produce with traditional machining. Larger, less complex objects also tend to lend themselves more to subtractive manufacturing. This machining process is also most often the choice for fabricating finished parts. Subtractive manufacturing processes can create parts for prototyping, manufacturing tooling, and end-use parts. The following projects showcase how subtractive manufacturing processes are leading innovations in design and construction, and what the future of these methods might hold.

By Bernard Tschumi Architects, Tianjin, China

The Binhai Science Museum was designed to showcase artifacts from Tianjin’s industrial past through large-scale contemporary technology, including spectacular rockets for space research. The project is part of the city’s Binhai Cultural Center and contains facilities for cultural events and exhibitions as well as galleries, offices, and restaurant and retail spaces. The project was made to relate to the rich industrial history of the area, the site of high-volume manufacturing and research. A series of large-scale cones create major rooms throughout the museum. The central cone, lit from above, connects all three levels of the building.

The Binhai Science Museum was designed to showcase artifacts from Tianjin’s industrial past through large-scale contemporary technology, including spectacular rockets for space research. The project is part of the city’s Binhai Cultural Center and contains facilities for cultural events and exhibitions as well as galleries, offices, and restaurant and retail spaces. The project was made to relate to the rich industrial history of the area, the site of high-volume manufacturing and research. A series of large-scale cones create major rooms throughout the museum. The central cone, lit from above, connects all three levels of the building.

The exterior of the museum is covered with aluminum rain screen over a sealed aluminum surface, giving the building a unified presence despite its large size and the disparate elements of the structure. Approximately 3,600 copper-colored panels in two sizes (4×7 ft and 4×11.5 ft) make up the flat portions of the building’s façade. The perforated metal panels also help reduce heat gain. The design team developed 52 different sizes of panels with each row of the cones corresponding to a unique width. Each panel is backed by two aluminum U-channels located between the perforations.

The exterior of the museum is covered with aluminum rain screen over a sealed aluminum surface, giving the building a unified presence despite its large size and the disparate elements of the structure. Approximately 3,600 copper-colored panels in two sizes (4×7 ft and 4×11.5 ft) make up the flat portions of the building’s façade. The perforated metal panels also help reduce heat gain. The design team developed 52 different sizes of panels with each row of the cones corresponding to a unique width. Each panel is backed by two aluminum U-channels located between the perforations.

By Acton Ostry Architects, Vancouver, Canada

Completed in 2017, Brock Commons Tallwood House is an 18-story, LEED Gold certified, 404-bed student residence building located at the University of British Columbia in Vancouver, BC. It was the world’s tallest mass wood tower at the time of its completion. The timber structure and prefabricated facade also went up in only 66 days.

Completed in 2017, Brock Commons Tallwood House is an 18-story, LEED Gold certified, 404-bed student residence building located at the University of British Columbia in Vancouver, BC. It was the world’s tallest mass wood tower at the time of its completion. The timber structure and prefabricated facade also went up in only 66 days.

Key to receiving approvals and achieving economic viability was a “keep it simple” design approach that makes the building appear ordinary through encapsulation of the wood structure with gypsum board. The prefabricated facade, arranged in a pattern of vertical striations, features pre-installed windows and cladding consisting of 70% wood fibers.

A CLT canopy runs the length of a curtain wall base, which reveals the warm wood finishes of amenity spaces within. Elevator lobbies are clad with the same material as the exterior. Hallway finishes include natural wood doors and a palette of rich umber and ochre accent finishes. Living unit interiors are bright white, spare and simple.

A CLT canopy runs the length of a curtain wall base, which reveals the warm wood finishes of amenity spaces within. Elevator lobbies are clad with the same material as the exterior. Hallway finishes include natural wood doors and a palette of rich umber and ochre accent finishes. Living unit interiors are bright white, spare and simple.

CNC machines cut all the mass-timber components, including the penetrations in the CLT panels and the connection holes in both ends of the columns. A unique identifier was assigned to each mass-timber component for quality-assurance and quality-control tracking and on-site measurement of the structural system assembly heights.

By Morphosis Architects, New York, NY, United States

The Emma and Georgina Bloomberg Center is the academic hub of the new Cornell Tech campus on Roosevelt Island. With the goal of becoming a net zero building, The Bloomberg Center forms the heart of the campus, bridging academia and industry while pioneering new standards in environmental sustainability through state-of-the-art design. T

The Emma and Georgina Bloomberg Center is the academic hub of the new Cornell Tech campus on Roosevelt Island. With the goal of becoming a net zero building, The Bloomberg Center forms the heart of the campus, bridging academia and industry while pioneering new standards in environmental sustainability through state-of-the-art design. T

he Bloomberg Center is a four-story building set beneath a photovoltaic canopy, with a low and narrow profile framing stunning views across the island. One of the building’s most distinctive features is its façade, optimized to balance transparency —maximizing daylighting and exterior views, and opacity — while ensuring sufficient insulation and reducing thermal bridging.

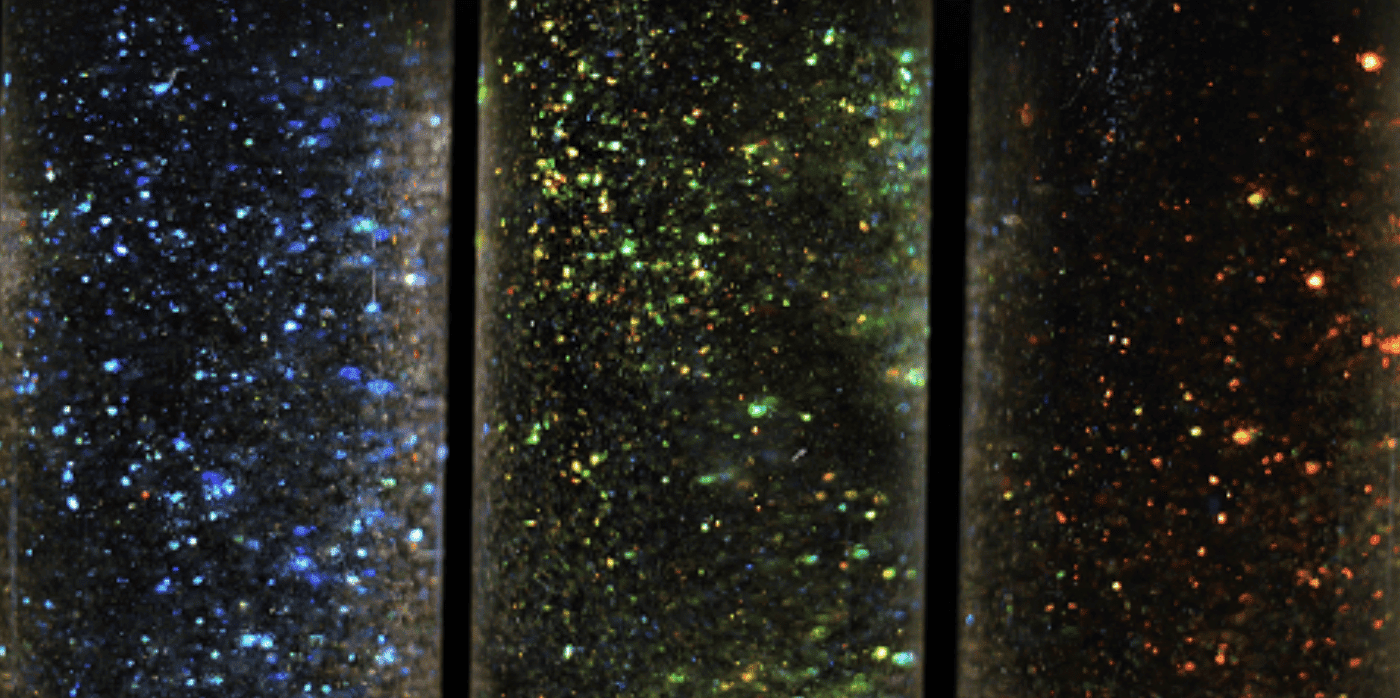

Designed as a rain screen system, the outermost layer of the façade is composed of aluminum panels surfaced in an iridescent, PPG polymer coating. Designed in collaboration with Zahner, an architectural metal fabricator, the façade utilizes Zahner’s Louvered ZIRA™ system to create the image patterning.

Designed as a rain screen system, the outermost layer of the façade is composed of aluminum panels surfaced in an iridescent, PPG polymer coating. Designed in collaboration with Zahner, an architectural metal fabricator, the façade utilizes Zahner’s Louvered ZIRA™ system to create the image patterning.

Each pixel of the image is translated into the specific turn-and-tilt of a two-inch circular tab punched into the aluminum paneling; the depth and rotation of each tab determines the amount of light reflected. This pixel map was fed into a repurposed welding robot, which processed the digital information into the mechanical turning-and-tilting of the façade’s 337,500 tabs.

By Partisans, Georgian Bay, Canada

Perched on an island’s edge in Georgian Bay, Ontario, the Grotto Sauna is a feat of old-world craftsmanship and new world sustainability made possible by cutting-edge software and fabrication technology. The selected concept for the Grotto prescribed a solid, simple presence on the exterior, while the interior followed dynamic air movements in curvature forms; requiring design solutions.

Perched on an island’s edge in Georgian Bay, Ontario, the Grotto Sauna is a feat of old-world craftsmanship and new world sustainability made possible by cutting-edge software and fabrication technology. The selected concept for the Grotto prescribed a solid, simple presence on the exterior, while the interior followed dynamic air movements in curvature forms; requiring design solutions.

As a result, the team proceeded to experiment further with the materials, and selected wood as the primary medium. Importantly, the Grotto established a successful methodology for addressing the challenges of building ambitious architecture in remote and environmentally sensitive regions.

Partisans collaborated directly with their fabrication partner, MCM Inc., to develop new prototyping methods and with engineers and develop novel software patches for the toolpaths. The latter enabled the fabricators to override the automated limitations of the CNC machinery and ultimately use it as a sculpting tool to achieve the aesthetic vision, all the while maximizing the available wood and milling along the grain so that the pieces would match one another. The successful production of the panels also had to anticipate the method by which they would be sequentially assembled. This required the team to develop a sophisticated installation plan in tandem with the fabrication process.

Partisans collaborated directly with their fabrication partner, MCM Inc., to develop new prototyping methods and with engineers and develop novel software patches for the toolpaths. The latter enabled the fabricators to override the automated limitations of the CNC machinery and ultimately use it as a sculpting tool to achieve the aesthetic vision, all the while maximizing the available wood and milling along the grain so that the pieces would match one another. The successful production of the panels also had to anticipate the method by which they would be sequentially assembled. This required the team to develop a sophisticated installation plan in tandem with the fabrication process.

By Bjarke Ingels Group and JDS Architects, København, Denmark

When Bjarke Ingels Group and JDS Architects set out to create The Mountain residential project, it was the 2nd generation of the VM Houses: same client, same size and same street. The program, however, is 2/3 parking and 1/3 living. What if the parking area became the base upon which to place terraced housing, like a concrete hillside covered by a thin layer of housing cascading from the 11th floor to the street edge? Rather than doing two separate buildings next to each other — a parking and a housing block — the team decided to merge the two functions into a symbiotic relationship.

When Bjarke Ingels Group and JDS Architects set out to create The Mountain residential project, it was the 2nd generation of the VM Houses: same client, same size and same street. The program, however, is 2/3 parking and 1/3 living. What if the parking area became the base upon which to place terraced housing, like a concrete hillside covered by a thin layer of housing cascading from the 11th floor to the street edge? Rather than doing two separate buildings next to each other — a parking and a housing block — the team decided to merge the two functions into a symbiotic relationship.

The parking floors are covered with a continuous perforated aluminum surface, folding into four parts from the southern to the eastern facades. This controls sunlight and air circulation. The folded surface makes reference to the name of the project, displaying a realistic image of Mount Everest.

The parking floors are covered with a continuous perforated aluminum surface, folding into four parts from the southern to the eastern facades. This controls sunlight and air circulation. The folded surface makes reference to the name of the project, displaying a realistic image of Mount Everest.

For its aluminum panel facade, each perforation plays a specific part in the composition of the image. In some parts, perforations are so large and dense that there is almost no visual restriction between inside and outside. During the day, the perforation in the aluminum plates appears black on the bright aluminum, and the mountain image resembles a roughly rasterized photo. At night time, the facade is lit from the inside and appears as a photo negative in different colors as each floor in the parking area has different colors.

Courtesy Portland CNC

Today, subtractive manufacturing is being radically reimagined. We are seeing projects where 4D self-transforming materials respond to changes in heat, sound, or moisture levels to change shape. Subtractive manufacturing also offers a variety of material and processing methods for diverse design applications. As the process of building evolves, the convergence of technologies opens new possibilities for architecture, design and machining.

Browse the Architizer Jobs Board and apply for architecture and design positions at some of the world’s best firms. Click here to sign up for our Jobs Newsletter.

Left to languish since 2010, the former Los Angeles Times printing plant has been masterfully reincarnated as a daring commercial workplace. Precise incisions have unfurled the monolithic concrete volume, drawing in daylight, air and views of the picturesque surrounding landscape.

Left to languish since 2010, the former Los Angeles Times printing plant has been masterfully reincarnated as a daring commercial workplace. Precise incisions have unfurled the monolithic concrete volume, drawing in daylight, air and views of the picturesque surrounding landscape.

In another life, this magnificent early 20th-century edifice supplied energy to its local district in Madrid. Having fallen into disuse, it was purchased and saved from the wrecking ball, unlike many of its contemporaries in the region who weren’t so lucky. Fittingly, it’s now the offices of Spanish infrastructure and energy company ACCIONA.

In another life, this magnificent early 20th-century edifice supplied energy to its local district in Madrid. Having fallen into disuse, it was purchased and saved from the wrecking ball, unlike many of its contemporaries in the region who weren’t so lucky. Fittingly, it’s now the offices of Spanish infrastructure and energy company ACCIONA.

After 30 years in the North Sea, this retired oil rig was brought ashore and transformed into an astounding public art installation. A challenging feat, the ambitious project channeled the expertise of scientists, engineers and artists. Now, it stands as a poignant catalyst for conversations about our treatment of inherited structures and the potential for creative regeneration.

After 30 years in the North Sea, this retired oil rig was brought ashore and transformed into an astounding public art installation. A challenging feat, the ambitious project channeled the expertise of scientists, engineers and artists. Now, it stands as a poignant catalyst for conversations about our treatment of inherited structures and the potential for creative regeneration.

Formerly a timber warehouse in the Houthaven neighborhood of Amsterdam, the airy proportions of this vast building have been utilized to create a blended commercial and recreational venue. Flexibility is at the core of the remarkable project – multipurpose work zones and elevated platforms feature furniture on castor wheels for a fluid and easily adaptable floor plan.

Formerly a timber warehouse in the Houthaven neighborhood of Amsterdam, the airy proportions of this vast building have been utilized to create a blended commercial and recreational venue. Flexibility is at the core of the remarkable project – multipurpose work zones and elevated platforms feature furniture on castor wheels for a fluid and easily adaptable floor plan.

This ground-breaking project is setting a new precedent for the design of recording studios and post-production spaces. Nestled in the bustling heart of Prague in an old factory building dating back to 1908, the structure has come full circle. Once a place where electrical cables were manufactured, somewhat poetically, it’s now occupied by professionals who utilize an abundance of cables every day.

This ground-breaking project is setting a new precedent for the design of recording studios and post-production spaces. Nestled in the bustling heart of Prague in an old factory building dating back to 1908, the structure has come full circle. Once a place where electrical cables were manufactured, somewhat poetically, it’s now occupied by professionals who utilize an abundance of cables every day.

This extraordinary coworking space in Barcelona is an eloquent exercise in unearthing the past. The empathetic remodel is the latest in the building’s long history and sought to create a palpable connection between past and present.

This extraordinary coworking space in Barcelona is an eloquent exercise in unearthing the past. The empathetic remodel is the latest in the building’s long history and sought to create a palpable connection between past and present.

Older commercial buildings are often threatened with demolition in the name of urban development. However, this whimsical reuse scheme is a masterclass in reinvention. Once a neglected structure on the corner of a busy thoroughfare, its story has been drastically rewritten.

Older commercial buildings are often threatened with demolition in the name of urban development. However, this whimsical reuse scheme is a masterclass in reinvention. Once a neglected structure on the corner of a busy thoroughfare, its story has been drastically rewritten.

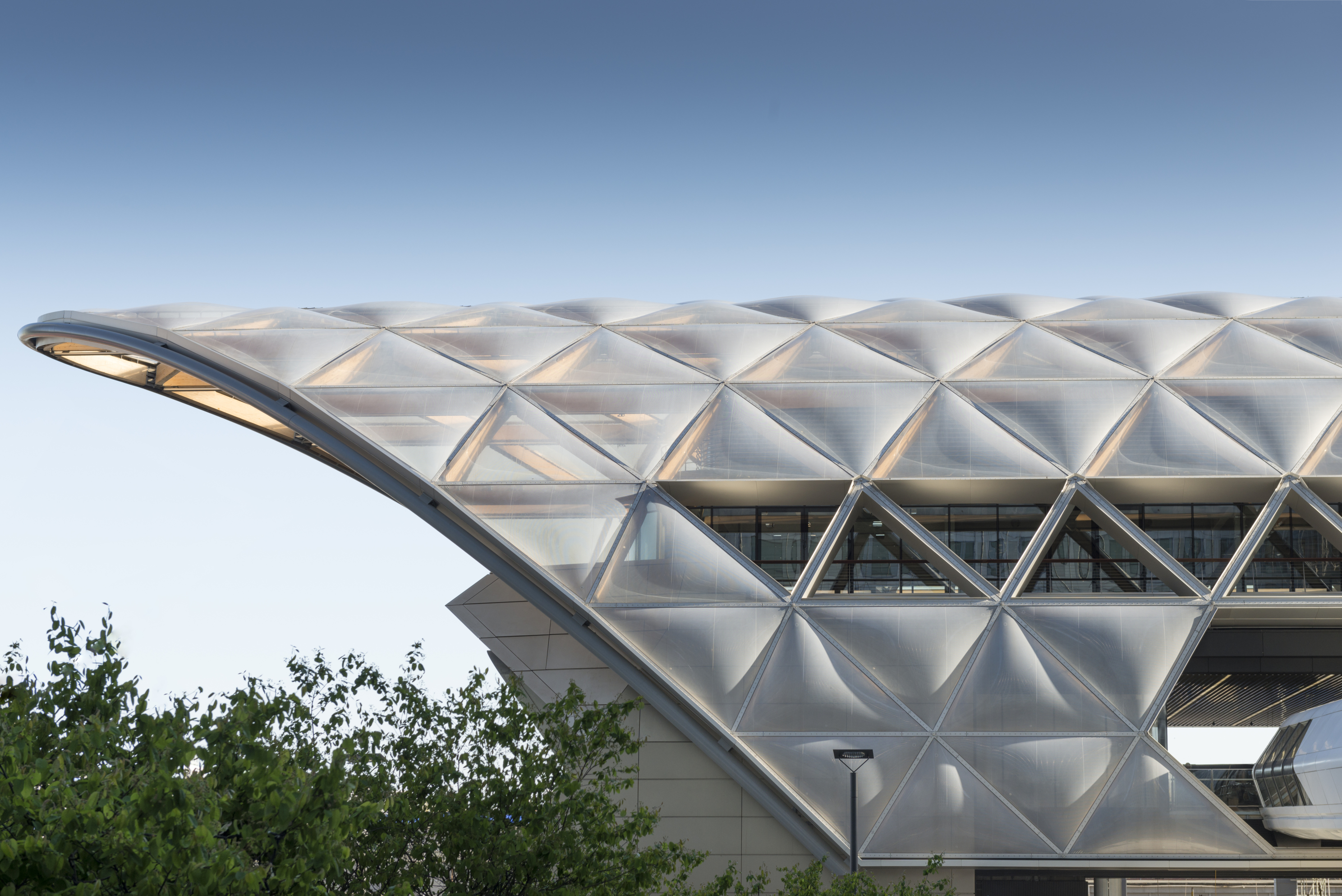

For the Bjergsted Financial Park in Stavanger, Sparebank 1 SR-Bank wanted a place where the company could realize its visions and offer the best for the surroundings. This seven-floor high building is an example of a future workplace and is one of Europe’s largest office buildings in timber. The volume varies in height to accommodate the varied scales and character of the surrounding buildings. There is a central atrium which brings in light, air and green qualities into the building. Social areas and meeting rooms are organized around this space and act as a buffer towards the quieter workplaces along the façades of the building. The galleries are connected by a spectacular open stair. There is a strong contrast between the sharp, triangulated exterior of glass and metal, against the interior organic design in timber.

For the Bjergsted Financial Park in Stavanger, Sparebank 1 SR-Bank wanted a place where the company could realize its visions and offer the best for the surroundings. This seven-floor high building is an example of a future workplace and is one of Europe’s largest office buildings in timber. The volume varies in height to accommodate the varied scales and character of the surrounding buildings. There is a central atrium which brings in light, air and green qualities into the building. Social areas and meeting rooms are organized around this space and act as a buffer towards the quieter workplaces along the façades of the building. The galleries are connected by a spectacular open stair. There is a strong contrast between the sharp, triangulated exterior of glass and metal, against the interior organic design in timber.

The New Aspen Art Museum is located in the center of the high mountain town of Aspen Colorado on a prominent downtown corner site. The three story kunsthalle provides galleries on the first two floors above ground level and on one floor below. The third floor is a multi-function space and café. Half of the third area is given over to an outdoor terrace with views up to the mountains. Design features include an innovative long-span timber space-frame roof structure, woven panel façade, structural glass floors for gallery day-lighting, outdoor gallery stair which connects the site plaza to the third floor roof level and glass elevator.

The New Aspen Art Museum is located in the center of the high mountain town of Aspen Colorado on a prominent downtown corner site. The three story kunsthalle provides galleries on the first two floors above ground level and on one floor below. The third floor is a multi-function space and café. Half of the third area is given over to an outdoor terrace with views up to the mountains. Design features include an innovative long-span timber space-frame roof structure, woven panel façade, structural glass floors for gallery day-lighting, outdoor gallery stair which connects the site plaza to the third floor roof level and glass elevator.

This mixed-use scheme was designed to encompass the over-ground elements of a new station for the Crossrail project at Canary Wharf. At the heart of the project was a new enclosure unifying the station and other elements including new retail units and a park. The park and the rest of the building is enclosed by a distinctive roof, which wraps around the building like a protective shell. This 300 meter-long (328 yard) timber lattice roof opens in the centre to draw in light and rain for natural irrigation. Timber was an appropriate material to enclose the park: it is organic in nature and appearance, strong, adaptable and is sustainably sourced. Despite the smooth curve of the enclosure, there are only four curved timber beams in the whole structure.

This mixed-use scheme was designed to encompass the over-ground elements of a new station for the Crossrail project at Canary Wharf. At the heart of the project was a new enclosure unifying the station and other elements including new retail units and a park. The park and the rest of the building is enclosed by a distinctive roof, which wraps around the building like a protective shell. This 300 meter-long (328 yard) timber lattice roof opens in the centre to draw in light and rain for natural irrigation. Timber was an appropriate material to enclose the park: it is organic in nature and appearance, strong, adaptable and is sustainably sourced. Despite the smooth curve of the enclosure, there are only four curved timber beams in the whole structure.

Looking to introduce warmth and light into this unique site, this home was built on the location of the former Housing Expo from ninety years ago. Orientation and shape of the surrounding residential area influenced the silhouette of the structure’s west elevation. A gable roof blends into the neighborhood and draws an arc towards the west side, showing a hint of modernism. To give a warm impression to the exterior facade, natural wood materials were used, where walls stand as a white canvas that complements cherry blossoms in season. The timber structure is enhanced by the transparency of glass, which draws attention from the eye-level pedestrian on the first floor.

Looking to introduce warmth and light into this unique site, this home was built on the location of the former Housing Expo from ninety years ago. Orientation and shape of the surrounding residential area influenced the silhouette of the structure’s west elevation. A gable roof blends into the neighborhood and draws an arc towards the west side, showing a hint of modernism. To give a warm impression to the exterior facade, natural wood materials were used, where walls stand as a white canvas that complements cherry blossoms in season. The timber structure is enhanced by the transparency of glass, which draws attention from the eye-level pedestrian on the first floor.

Created to be a modular classroom, this timber design includes the construction of a prototype module for environmental education, a learning and discovery space to be installed in different locations of the Metropolitan Area of Barcelona park’s network. It is proposed that it becomes also the habitat for some species of animals such as insects, invertebrates, birds, bats… As the team explained, it must be a space open to the outside; it is necessary that one could see the trees from the classroom, to perceive the light and feel the climate. The building was planned as a prefabricated module, flexible and as economical as possible, capable of responding to the different requirements of each municipality for environmental education.

Created to be a modular classroom, this timber design includes the construction of a prototype module for environmental education, a learning and discovery space to be installed in different locations of the Metropolitan Area of Barcelona park’s network. It is proposed that it becomes also the habitat for some species of animals such as insects, invertebrates, birds, bats… As the team explained, it must be a space open to the outside; it is necessary that one could see the trees from the classroom, to perceive the light and feel the climate. The building was planned as a prefabricated module, flexible and as economical as possible, capable of responding to the different requirements of each municipality for environmental education.

As the design team explored in Timber Rhyme, wood-art has been an integral part of Indian history. Sutradhar community, according to legend, are the carpenters (also known as ‘badhaee’) descended from Maya, the son of Vishwakarma (the divine engineer). This design explored conventional limitations of the material sold by the client, veneers and plywood, and its protagonist role in a conversation that has existed in the ancient past. ‘Timber Rhyme’ occupies the first story of a retail shop in a market complex, Chandigarh. The challenge was to invite a walk through the existing 71′ by 18′ linear block. A timber ribbon invites passerby into the space and to engage with the materials.

As the design team explored in Timber Rhyme, wood-art has been an integral part of Indian history. Sutradhar community, according to legend, are the carpenters (also known as ‘badhaee’) descended from Maya, the son of Vishwakarma (the divine engineer). This design explored conventional limitations of the material sold by the client, veneers and plywood, and its protagonist role in a conversation that has existed in the ancient past. ‘Timber Rhyme’ occupies the first story of a retail shop in a market complex, Chandigarh. The challenge was to invite a walk through the existing 71′ by 18′ linear block. A timber ribbon invites passerby into the space and to engage with the materials.

When considering the design expression for a new archery hall and boxing club, FT Architects created a pair of buildings a few hundred meters apart on the grounds of Kogakuin University in west Tokyo. The University’s brief was for low-cost structures made of locally sourced timber to provide accessible and inspiring spaces for the students. By chance, both facilities called for a column-free space scaled to a size comparable to a sacred hall in a traditional Japanese temple.

When considering the design expression for a new archery hall and boxing club, FT Architects created a pair of buildings a few hundred meters apart on the grounds of Kogakuin University in west Tokyo. The University’s brief was for low-cost structures made of locally sourced timber to provide accessible and inspiring spaces for the students. By chance, both facilities called for a column-free space scaled to a size comparable to a sacred hall in a traditional Japanese temple.

The Binhai Science Museum was designed to showcase artifacts from Tianjin’s industrial past through large-scale contemporary technology, including spectacular rockets for space research. The project is part of the city’s Binhai Cultural Center and contains facilities for cultural events and exhibitions as well as galleries, offices, and restaurant and retail spaces. The project was made to relate to the rich industrial history of the area, the site of high-volume manufacturing and research. A series of large-scale cones create major rooms throughout the museum. The central cone, lit from above, connects all three levels of the building.

The Binhai Science Museum was designed to showcase artifacts from Tianjin’s industrial past through large-scale contemporary technology, including spectacular rockets for space research. The project is part of the city’s Binhai Cultural Center and contains facilities for cultural events and exhibitions as well as galleries, offices, and restaurant and retail spaces. The project was made to relate to the rich industrial history of the area, the site of high-volume manufacturing and research. A series of large-scale cones create major rooms throughout the museum. The central cone, lit from above, connects all three levels of the building. The exterior of the museum is covered with aluminum rain screen over a sealed aluminum surface, giving the building a unified presence despite its large size and the disparate elements of the structure. Approximately 3,600 copper-colored panels in two sizes (4×7 ft and 4×11.5 ft) make up the flat portions of the building’s façade. The perforated metal panels also help reduce heat gain. The design team developed 52 different sizes of panels with each row of the cones corresponding to a unique width. Each panel is backed by two aluminum U-channels located between the perforations.

The exterior of the museum is covered with aluminum rain screen over a sealed aluminum surface, giving the building a unified presence despite its large size and the disparate elements of the structure. Approximately 3,600 copper-colored panels in two sizes (4×7 ft and 4×11.5 ft) make up the flat portions of the building’s façade. The perforated metal panels also help reduce heat gain. The design team developed 52 different sizes of panels with each row of the cones corresponding to a unique width. Each panel is backed by two aluminum U-channels located between the perforations.

Completed in 2017, Brock Commons Tallwood House is an 18-story, LEED Gold certified, 404-bed student residence building located at the University of British Columbia in Vancouver, BC. It was the world’s tallest mass wood tower at the time of its completion. The timber structure and prefabricated facade also went up in only 66 days.

Completed in 2017, Brock Commons Tallwood House is an 18-story, LEED Gold certified, 404-bed student residence building located at the University of British Columbia in Vancouver, BC. It was the world’s tallest mass wood tower at the time of its completion. The timber structure and prefabricated facade also went up in only 66 days. A CLT canopy runs the length of a curtain wall base, which reveals the warm wood finishes of amenity spaces within. Elevator lobbies are clad with the same material as the exterior. Hallway finishes include natural wood doors and a palette of rich umber and ochre accent finishes. Living unit interiors are bright white, spare and simple.

A CLT canopy runs the length of a curtain wall base, which reveals the warm wood finishes of amenity spaces within. Elevator lobbies are clad with the same material as the exterior. Hallway finishes include natural wood doors and a palette of rich umber and ochre accent finishes. Living unit interiors are bright white, spare and simple.

The Emma and Georgina Bloomberg Center is the academic hub of the new Cornell Tech campus on Roosevelt Island. With the goal of becoming a net zero building, The Bloomberg Center forms the heart of the campus, bridging academia and industry while pioneering new standards in environmental sustainability through state-of-the-art design. T

The Emma and Georgina Bloomberg Center is the academic hub of the new Cornell Tech campus on Roosevelt Island. With the goal of becoming a net zero building, The Bloomberg Center forms the heart of the campus, bridging academia and industry while pioneering new standards in environmental sustainability through state-of-the-art design. T Designed as a rain screen system, the outermost layer of the façade is composed of aluminum panels surfaced in an iridescent, PPG polymer coating. Designed in collaboration with Zahner, an architectural metal fabricator, the façade utilizes Zahner’s Louvered ZIRA™ system to create the image patterning.

Designed as a rain screen system, the outermost layer of the façade is composed of aluminum panels surfaced in an iridescent, PPG polymer coating. Designed in collaboration with Zahner, an architectural metal fabricator, the façade utilizes Zahner’s Louvered ZIRA™ system to create the image patterning.

Perched on an island’s edge in Georgian Bay, Ontario, the Grotto Sauna is a feat of old-world craftsmanship and new world sustainability made possible by cutting-edge software and fabrication technology. The selected concept for the Grotto prescribed a solid, simple presence on the exterior, while the interior followed dynamic air movements in curvature forms; requiring design solutions.

Perched on an island’s edge in Georgian Bay, Ontario, the Grotto Sauna is a feat of old-world craftsmanship and new world sustainability made possible by cutting-edge software and fabrication technology. The selected concept for the Grotto prescribed a solid, simple presence on the exterior, while the interior followed dynamic air movements in curvature forms; requiring design solutions. Partisans collaborated directly with their fabrication partner, MCM Inc., to develop new prototyping methods and with engineers and develop novel software patches for the toolpaths. The latter enabled the fabricators to override the automated limitations of the CNC machinery and ultimately use it as a sculpting tool to achieve the aesthetic vision, all the while maximizing the available wood and milling along the grain so that the pieces would match one another. The successful production of the panels also had to anticipate the method by which they would be sequentially assembled. This required the team to develop a sophisticated installation plan in tandem with the fabrication process.

Partisans collaborated directly with their fabrication partner, MCM Inc., to develop new prototyping methods and with engineers and develop novel software patches for the toolpaths. The latter enabled the fabricators to override the automated limitations of the CNC machinery and ultimately use it as a sculpting tool to achieve the aesthetic vision, all the while maximizing the available wood and milling along the grain so that the pieces would match one another. The successful production of the panels also had to anticipate the method by which they would be sequentially assembled. This required the team to develop a sophisticated installation plan in tandem with the fabrication process.

When Bjarke Ingels Group and JDS Architects set out to create The Mountain residential project, it was the 2nd generation of the VM Houses: same client, same size and same street. The program, however, is 2/3 parking and 1/3 living. What if the parking area became the base upon which to place terraced housing, like a concrete hillside covered by a thin layer of housing cascading from the 11th floor to the street edge? Rather than doing two separate buildings next to each other — a parking and a housing block — the team decided to merge the two functions into a symbiotic relationship.

When Bjarke Ingels Group and JDS Architects set out to create The Mountain residential project, it was the 2nd generation of the VM Houses: same client, same size and same street. The program, however, is 2/3 parking and 1/3 living. What if the parking area became the base upon which to place terraced housing, like a concrete hillside covered by a thin layer of housing cascading from the 11th floor to the street edge? Rather than doing two separate buildings next to each other — a parking and a housing block — the team decided to merge the two functions into a symbiotic relationship. The parking floors are covered with a continuous perforated aluminum surface, folding into four parts from the southern to the eastern facades. This controls sunlight and air circulation. The folded surface makes reference to the name of the project, displaying a realistic image of Mount Everest.

The parking floors are covered with a continuous perforated aluminum surface, folding into four parts from the southern to the eastern facades. This controls sunlight and air circulation. The folded surface makes reference to the name of the project, displaying a realistic image of Mount Everest.