Revolutionising recycling with AI-enabled robots

Spotted: Even in areas that have established comprehensive recycling systems, very often huge amounts of recyclables don’t actually end up getting recycled. In the UK, recycling rates have ‘plateaued’ at around 43 per cent in recent years, while in the US, almost 70 per cent of municipal waste doesn’t get recycled or composted.

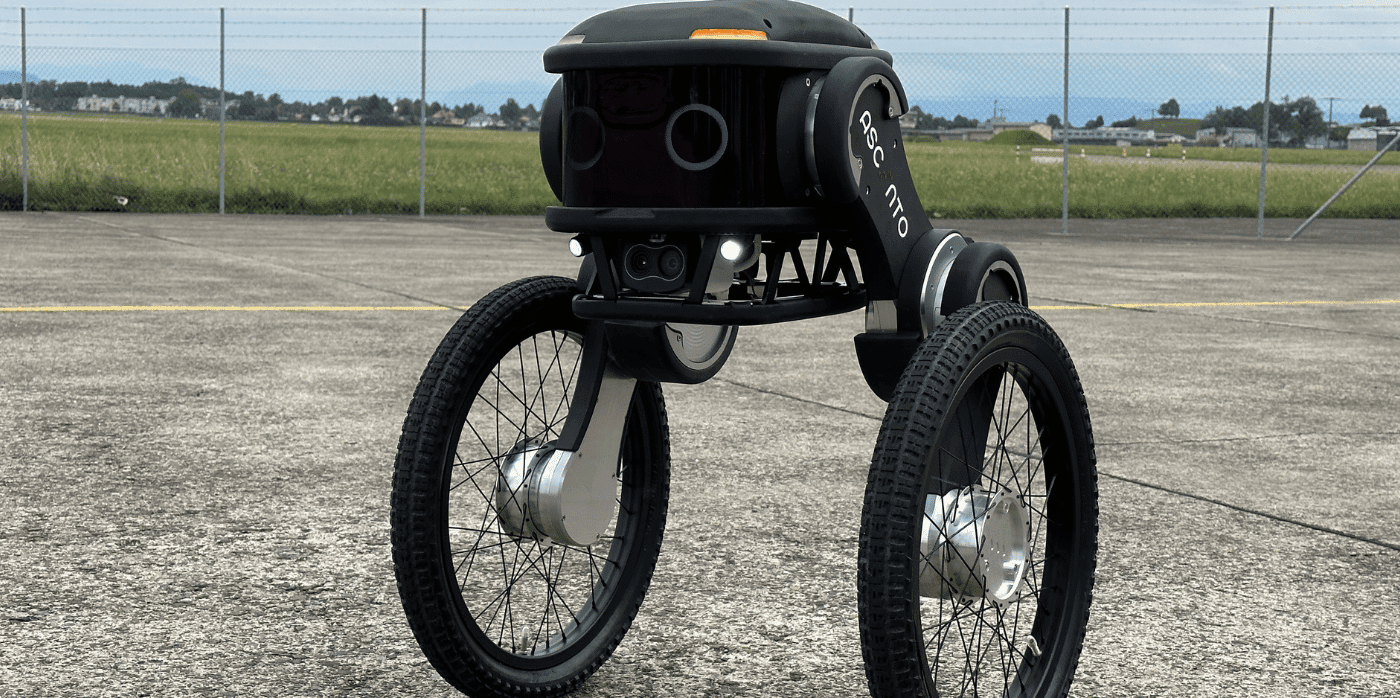

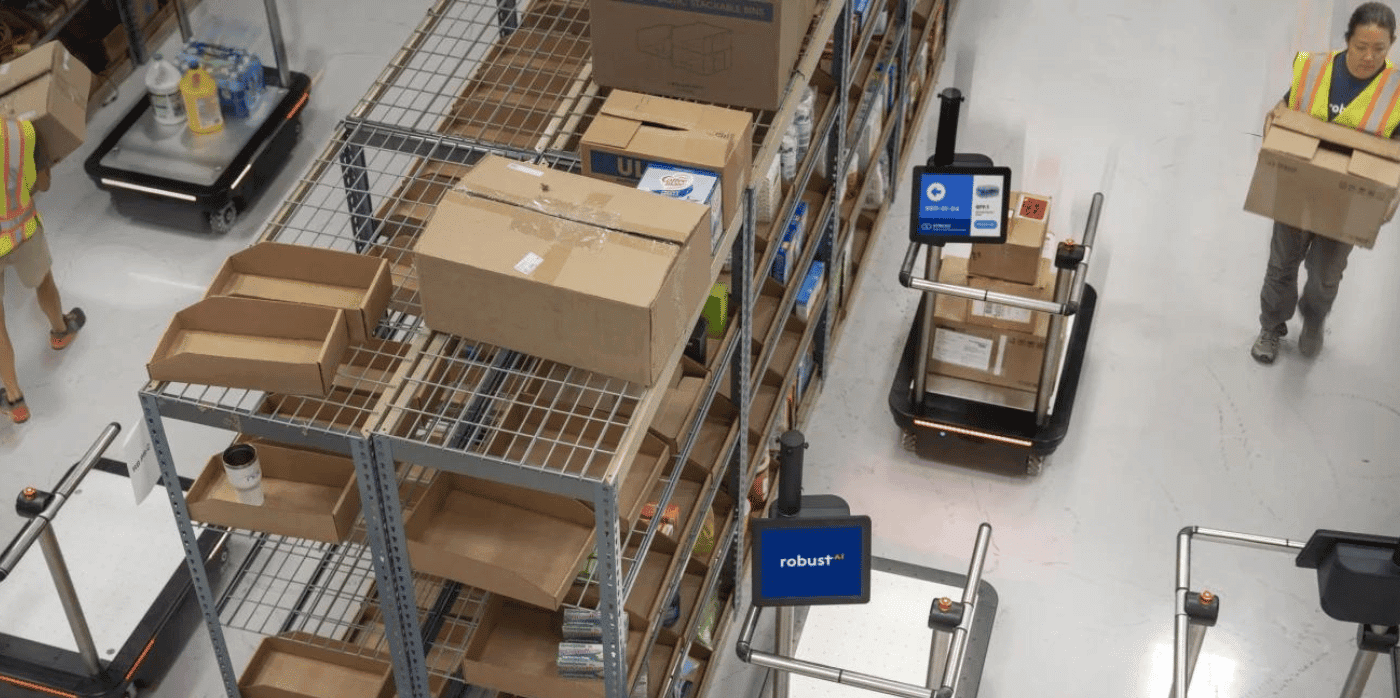

Enter Glacier, which has developed an AI-enabled sorting robot to help materials recycling facilities more efficiently separate individual recyclables. The robots can accurately identify more than 30 different types of recyclables as they move along conveyor belts. In addition, the robots collect real-time data on the volume of recyclables, contamination rates, and other details.

The robot takes up about the space as a human, can achieve cost payback in as little as six months, and can be installed with no downtime or heavy machinery. The company’s co-founder, Areeb Malik, told Springwise that “existing sortation solutions were too expensive, difficult to install, and expensive to maintain and repair.” Glacier’s robot, in contrast, is “purpose-built to solve these exact pain points.”

Glacier, which is led by a female CEO, earlier completed a $4.5 million (around €4.1 million) seed round led by venture firm New Enterprise Associates (NEA). More recently, the company has received an additional $7.7 million (around €7 million) in funding from NEA and Amazon’s Climate Pledge Fund, with additional participation from other investors. Malik explained that the technology is already live in about a dozen facilities across the US and the company expects significant growth going forward.

There is increasing urgency in finding solutions to the world’s growing waste problem. Springwise has recently spotted the use of plastic waste as a bitumen replacement and AI technology that combats food waste.

Written By: Lisa Magloff