We need to design for human behaviour to get rid of single-use plastics

Packaging designs aimed at boosting recycling rates and reducing the prevalence of single-use plastics are destined to fail unless they help to change people’s behaviour, writes Matt Millington.

No one is particularly happy when they find out there’s plastic waste on Mount Everest, or in the deep oceans, or in human blood. It’s not controversial to say that we need to stop churning the stuff out and throwing it away.

One way for businesses to tackle single-use plastics is to design their packaging to be reusable, but so far efforts have not succeeded at scale.

For example, reusable McDonald’s cups are only getting a 40 per cent return rate from customers in Germany, despite consumers paying a €2 deposit. When Starbucks trialled reusable cups in the closed environment of its Seattle HQ, where returning them is presumably straightforward, the return rate still didn’t exceed 80 per cent.

We weren’t exactly succumbing to dehydration on the streets before coffee shops designed takeaway cups

It’s not that we don’t care: research suggests consumer motivation towards environmentally positive behaviour is high. It’s that as a society we have developed an expectation of convenience: to have what we want, when we want it, without any consequences.

This is entirely unreasonable – we weren’t exactly succumbing to dehydration on the streets before coffee shops designed takeaway cups – but while it persists, consumers are very unlikely to switch to reusable alternatives if it puts them out. And without a high return-and-reuse rate, reusable packaging is usually worse for the environment, owing to the much higher quantities of plastic involved.

This is why we need to design for human behaviour if we’re ever to get rid of single-use plastics. You cannot control what people will do with packaging once it leaves your premises, but you can influence them by factoring behavioural psychology into the design of the packaging itself.

The first step is understanding how consumers interact with the pack, throughout its lifecycle. Where are they and what are they doing when they open it? What’s their headspace? How about when they’re finished with it? There’s a big difference between how someone interacts with a reusable plate after a meal in a cafeteria, and how they interact with the reusable salad bowl they’re gobbling from on the lunchtime rush back to the office.

Then it’s about understanding the levers you can pull to nudge people towards more planet-positive decisions. Behavioural psychology shows there are three factors that work together to drive behavioural change: increasing consumer motivation to recycle or reuse, raising their ability to do so, and providing a trigger to remind them.

Take plastic bags. While usage of single-use bags has dramatically decreased in the UK since legislation requiring retailers to charge for them came into force in 2015, reusable alternatives have had mixed success. According to a report by the Environmental Investigation Agency and Greenpeace, 57 “bags for life” were sold for each household in the country in 2019 – more than one a week.

It’s possible to go too far in signalling that a pack isn’t disposable

Online grocer Ocado uses recyclable bags instead, but it has had success in achieving returns because it pulls all three behavioural psychology levers. Consumers are happy to receive bonus reward points for each bag they give back (motivation).

The bags are straightforward to return and customers know not to throw them away because of their clear messaging and distinct off-grey colour, which follows from not using harmful bleaching agents (ability). And because the driver usually asks for old bags after delivery, they’re unlikely to forget (trigger).

Ability is the key consideration. If you wanted to return the packaging from a takeaway burger meal, it would mean washing and then carrying around a bulky burger box, fries box and cup, and either making a special trip to the restaurant or waiting until you happen upon another branch.

New Zealand start-up FOLDPROJECT has done some interesting work here, trying to make boxes more portable. It’s a simple idea: a machine-washable lunch kit that packs down to a flat sheet. The challenge is that because it is so minimal, its form and material make it look disposable.

One way to ensure a reusable design communicates its intended purpose is through material choice. For example, using explicitly post-consumer recycled plastic could be a visual shorthand to communicate a planet-positive intent, as could using longer-lasting materials like glass or stoneware.

Interestingly, it’s possible to go too far in signalling that a pack isn’t disposable. When McDonald’s introduced reusable packaging in its restaurants in France, it found the packaging kept disappearing, only to reappear on eBay. It looked reusable and on-brand, but was too novel for some, defeating the object.

So long as we have bins on every street that lead directly to landfill, we are going to struggle

Businesses cannot just switch to reusable packaging – even when intelligently designed – and expect results. So long as we have bins on every street that lead directly to landfill we are going to struggle.

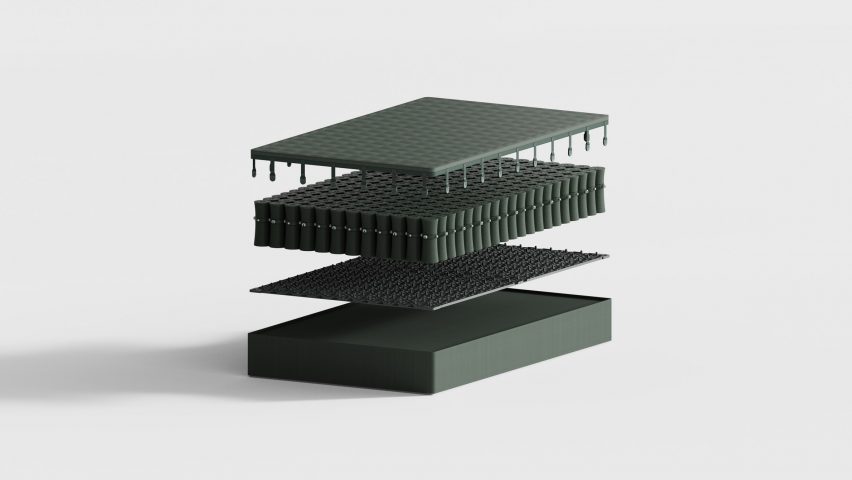

We therefore need to think beyond just designing the packaging to be sustainable, and think about how we design systems to be sustainable. In a circular economy that means service and experience design, packaging, industrial design, marketing, data, artificial intelligence and logistics all working hand-in-hand to keep the pack “in the loop”. It will therefore need to be an ecosystem effort.

We’re already seeing innovations that can help make reuse and return viable in the age of convenience. For example, when is a bin not a bin? When it’s a Bjarke Ingels Group-designed TURN system – a remote, digitally connected, RFID-enabled, packaging-asset reclaim and sorting network, which rejects unwanted trash.

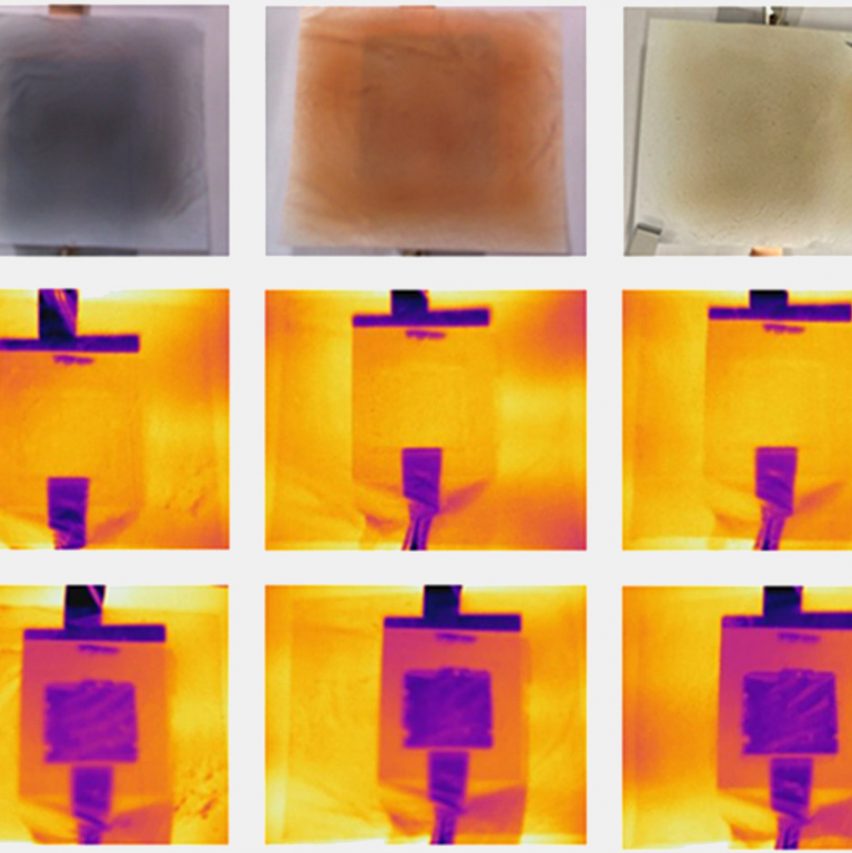

Similarly, we’re seeing nudge messaging along the pack journey, and even packs that communicate their status themselves. Scottish start-up Insignia has designed colour-changing labels that reveal how long a pack has been exposed to the environment. Imagine taking this further, with reusable packaging telling you what to do with it, and offering prompts or rewards to encourage you.

Reusability hasn’t hit scale yet, but we should be optimistic that it can, not least because we’ve been there before. Milk deliveries were once the norm, with bottles returned, not discarded.

There’s no reason that we can’t get back to this more sustainable approach across the board, without having to endure too much inconvenience. All that’s required is a little ingenuity, and a lot of collaboration.

The photography is by Jas Min via Unsplash.

Matt Millington is a sustainable-design strategist at PA Consulting.

Dezeen In Depth

If you enjoy reading Dezeen’s interviews, opinions and features, subscribe to Dezeen In Depth. Sent on the last Friday of each month, this newsletter provides a single place to read about the design and architecture stories behind the headlines.