Architizer is thrilled to announce the winners of the 11th Annual A+Awards! Interested in participating next season? Sign up for key information about the 12th Annual A+Awards, set to launch this fall.

The new EU Deforestation Regulation (EUDR) has now been enacted as part of the wider European Union Green Deal. This mandates heightened due diligence on the value chain for operators and traders in various commodities, including soy, palm oil, cattle, coffee and wood.

Between 1990 and 2008, the bloc’s imports in products now covered by the revised rules amounted to 36% of total associated deforestation worldwide. The changes won’t bring an end to this, but any firm that wants to do business in the economic union, no matter where their headquarters, now needs to prove sustainable sourcing of these materials and that products have not contributed to deforestation that occurred after 31st December 2020.

Last October, Construction Europe reported on a lack of EUDR preparedness across built environment sectors within the context of a rise in timber as a building material. The ‘plyscraper’ race is perhaps the most visible sign of this, with several World’s Tallest Timber Building hopefuls topping out in the past few years. Ascent by Korb + Associates currently holds the title in Milwaukee, US, at 284 feet (87 meters). This is followed by the 280-foot (85-meter) Mjøstårnet by Voll Arkitekter, in Brumunddal, Norway, and HoHo Wien by RLP Rüdiger Lainer + Partner, a Vienna mid-rise boasting 18 floors at 275 feet (84 meters).

Shor House by Measured Architecture Inc., Mayne Island, Canada | Photo by Ema Peter Photography

A little shorter, Sara Kulturhaus by White arkitekter AB in Skellefteå, Sweden, is a strong example of the carbon savings good timber design can offer. Housing a library, gallery, museum and hotel, over 50 years this 239 foot (73 meter) cross-laminated timber (CLT) design will sequester more carbon than the total of its embodied footprint from materials, transportation, construction and operation. The carbon negative status is thanks in part to properties of the core structure, but this isn’t always the case.

Two of construction and architecture’s greatest environmental adversaries are steel and concrete. But the widely-trumpeted climate gains from switching to timber aren’t guaranteed. The real test is always in the quality of what is built. In the best case scenarios, impacts from physical construction, ongoing use and material sourcing will be outweighed by carbon sequestration and storage capacity. In the worst, building with wood can be worse for the planet than its alternatives, but recycled timber is often a safe bet in ecological terms.

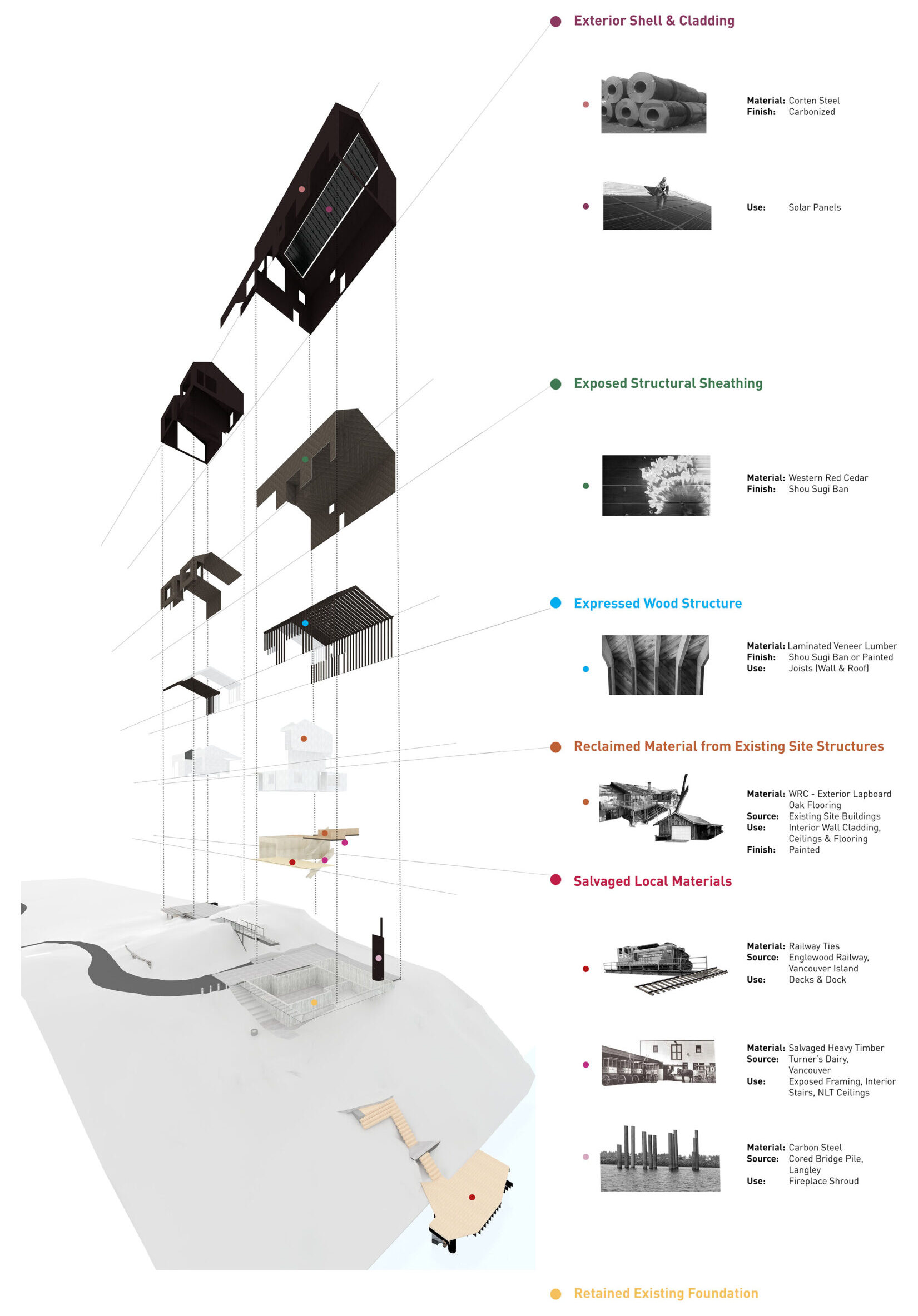

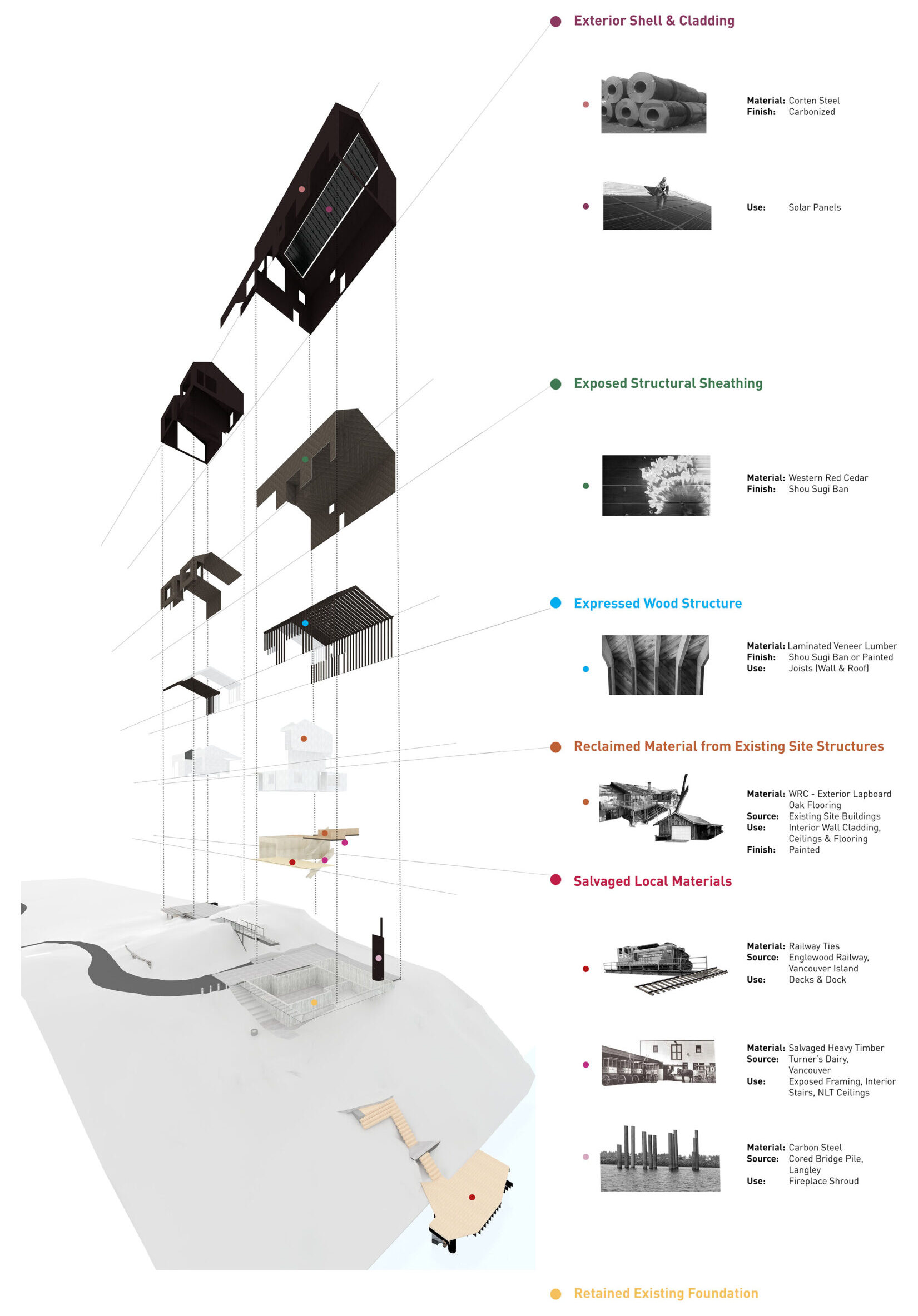

Measured Architecture Inc’s Shor House, Popular Choice Winner in Sustainable Private House at this year’s Architizer A+ Awards, is a beautiful example of what can be done with reclaimed wood. Completed in 2022, the design focuses on one truth: “The most progressive edge of designing with wood is to recycle it.” Much of the lumber was sourced from the old home and barn that occupied the site at Mayne Island, Canada. The original structures were dismantled rather than demolished, so cladding, floors and frames could be de-nailed, stored and reused.

Shor House by Measured Architecture Inc., Mayne Island, Canada | Photo by Ema Peter Photography

Some timber also came from the remnants of the Englewood Railroad, Northern Vancouver Island, which was decommissioned in 2017. The outside is then clad in Corten raw plate steel, chosen for its low upkeep and long lifespan. Architect and the property owner Clinton Cuddington describes the material as “eminently recyclable”, and its use emphasizes the importance of product diversity in green construction. Without this rust-colored layer, timber would be far more exposed to the elements, increasing the speed of degradation and likelihood of repairs. The steel also has the potential for reuse at a later date.

Of course, however it features recycled timber presents some problems. These woods are often thought of for the rustic aesthetics of a “past life effect.” Surfaces may be marked, nailed or chiseled, giving them stacks of personality but — crucially — often a lack of uniformity.

There’s also a cost issue. Reclaimed wood is usually priced higher than virgin timber because additional resources are needed to bring it back to spec. Toxins, contaminants, natural pests and other risks must be eliminated before it re-enters the supply chain. Nevertheless, the benefits are significant, not least in emissions terms. Recycled timber extends wood lifecycle, and with it the time carbon is stored before decomposition releases it into the atmosphere. At Shor House, dating suggests some lumber can be traced to trees that stood for 1,000 years.

Shor House by Measured Architecture Inc., Mayne Island, Canada | Photo by Ema Peter Photography

The materials certainly pack the aged, historic look people love reclaimed wood for, but elsewhere developments are underway that could bridge a gap between this and the mass timber many new wooden structures rely on, which can be a major cause of deforestation. University College London researcher Dr. Colin Rose won Rambøll’s 2022 Flemming Bligaard Award for his work on CLST, or cross laminated secondary timber, which uses reclaimed rather than virgin wood as the feedstock for ‘new’ CLT stock.

In an interview published when the prize was announced, Rose explains his belief this material can be a viable alternative to steel and concrete in strength, production levels and affordability. He also says built environment professionals have not caught up with CLST yet, and most still see the material as “in lab phase”. He then predicts this will change as embodied carbon begins to define our approach to construction, which CLST performs well on, as do recycled woods generally.

According to his estimates, you could build around 1,000 new homes each year using the discarded wood from building sites in London alone. Widening the lens, every 12 months we create 16 million tonnes of waste wood globally, and currently recycle just 15% of that. These facts emphasize the idea that access and systems are major obstacles to wider use of reclaimed timber, and how urgently change is needed to maximize the way lumber is used to minimize waste and deforestation. Achieving that requires a number of things, including the scaling up of operations and infrastructure, not to mention fresh thinking on the part of architects and designers.

Shor House by Measured Architecture Inc., Mayne Island, Canada | Photo by Ema Peter Photography

Architizer is thrilled to announce the winners of the 11th Annual A+Awards! Interested in participating next season? Sign up for key information about the 12th Annual A+Awards, set to launch this fall.

Whether they’re structure, infrastructure, or comfort and decor, we are selecting sustainable materials for how they will be used in our homes. It’s important to identify the key factors that impact how long you will utilize and enjoy a product. Here is where cost-effective and eco-friendly come into harmony. A product that is expensive to run is likely consuming energy and/or excessive resources and materials throughout its usable life. Interestingly, people are inclined to hold on to—or pass along for reuse—a product or building that functions flexibly, is durable, or brings delight. If you are less than satisfied, it’s likely headed for the curb no matter how much it cost.

Whether they’re structure, infrastructure, or comfort and decor, we are selecting sustainable materials for how they will be used in our homes. It’s important to identify the key factors that impact how long you will utilize and enjoy a product. Here is where cost-effective and eco-friendly come into harmony. A product that is expensive to run is likely consuming energy and/or excessive resources and materials throughout its usable life. Interestingly, people are inclined to hold on to—or pass along for reuse—a product or building that functions flexibly, is durable, or brings delight. If you are less than satisfied, it’s likely headed for the curb no matter how much it cost.