Smart threads for product traceability

Spotted: Most people are familiar with RFID tags – a type of tracking system that uses smart barcodes in order to identify items. RFID stands for “radio frequency identification,” and the tags use radio waves to transmit data from the tag to a reader. RFID tags have uses as disparate as tracking items in retail stores and warehouses, supply chain management, and tracking the movement of vehicles, pets, and even patients with Alzheimer’s disease.

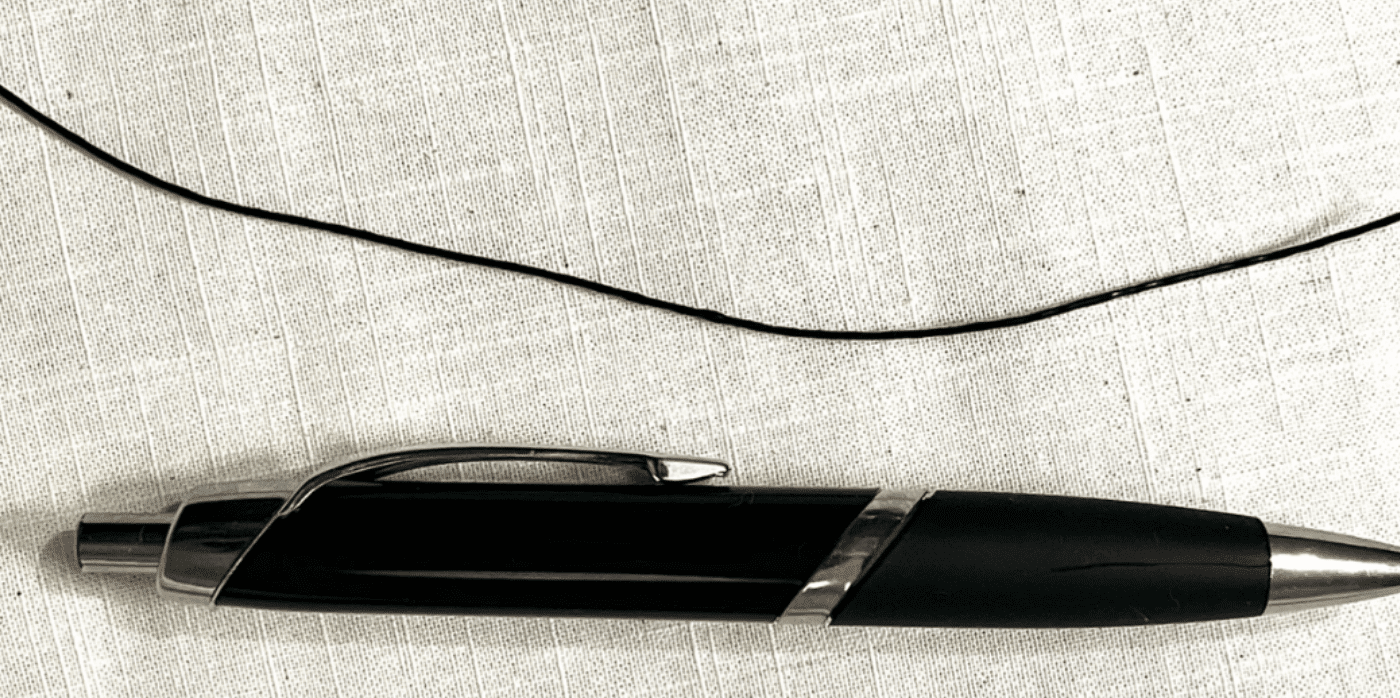

Now, Circlolink has developed RFID Threads, which it claims are the world’s first washable radio frequency digital ID that stays with the product. The radio transmitter is housed in a single smart thread that can be integrated into products, connecting them to a dedicated cloud platform. The RFID yarn can be inserted into products during manufacture and then all of the details of an item’s manufacture, sourcing, fibre types, and more can be easily tracked across its lifetime. The threads can be used in everything from clothing and mattresses to shoes and homeware, with Circlolink also testing thicker threads for incorporation into tyres.

Circlolink has partnered with e-textile company Adetex.CS, to provide the CIRCAA Cloud platform used to manage the data collected by the threads. The system also allows for the creation of digital product passports, unique QR Codes for customer engagement, and bulk scanning, and acts as a bridge to supply chain management systems.

The company recently launched its Digital Product Passport (DPP) Pilot Package wherein brands can trial the technology with 100 RFID threads, an RFID reader, and access to the CIRCAA app. In the longer term, Circlolink plans to begin distribution of the first 100 million threads over a two-year rollout period. The company points out that producing the threads in bulk will allow it to reduce the cost from $1.50 (around €1.42) per thread as part of the pilot scheme to just $0.11 (around €0.10) each, helping to make the technology as affordable and accessible as possible.

The new RFID threads join recent innovations seeking to improve circularity and traceability. These include a marketplace that connects fashion brands to deadstock materials and a circular marketplace for personal electronics.

Written By: Lisa Magloff